■ Movement Principle of Electric Screwdriver Controller ( DO-1390A )

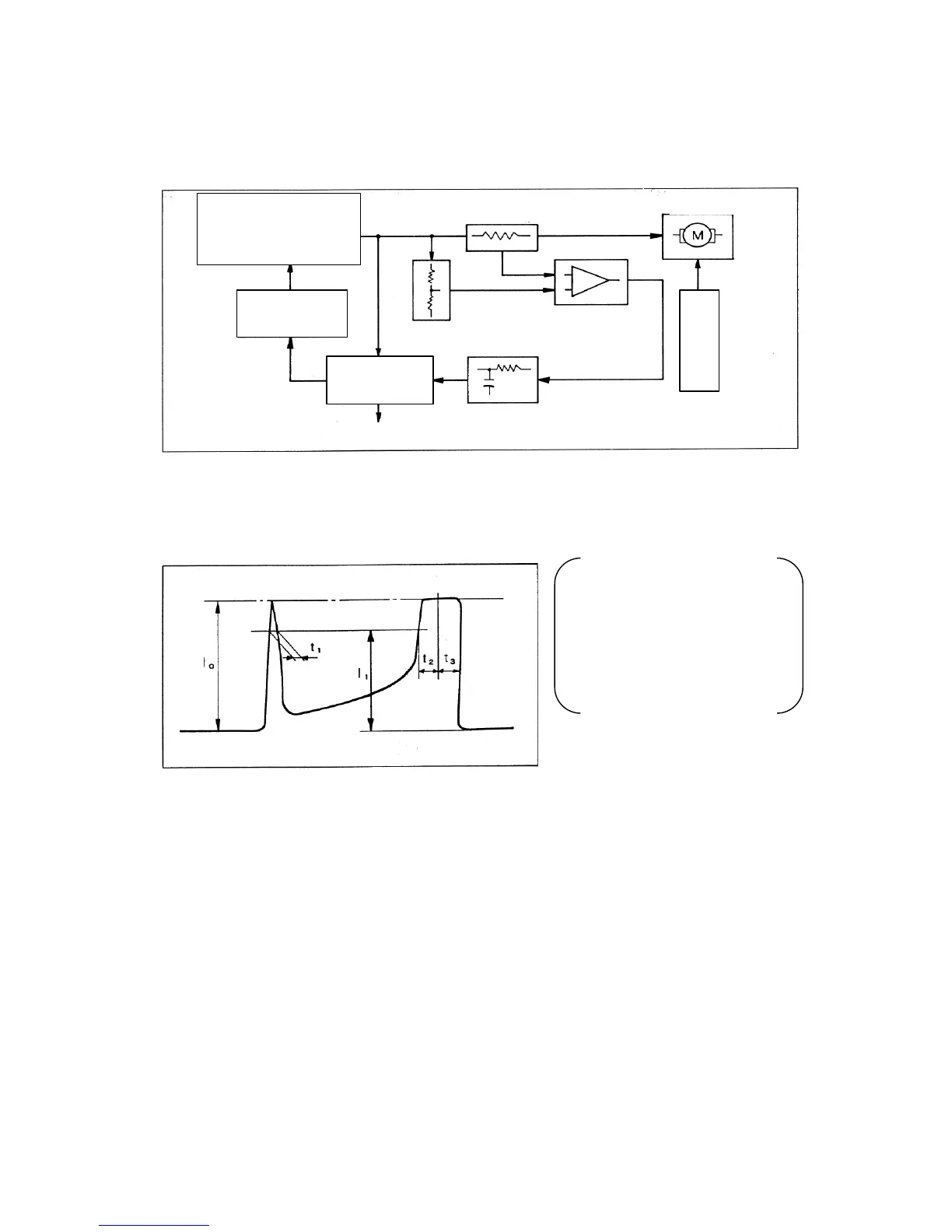

①Block chatr

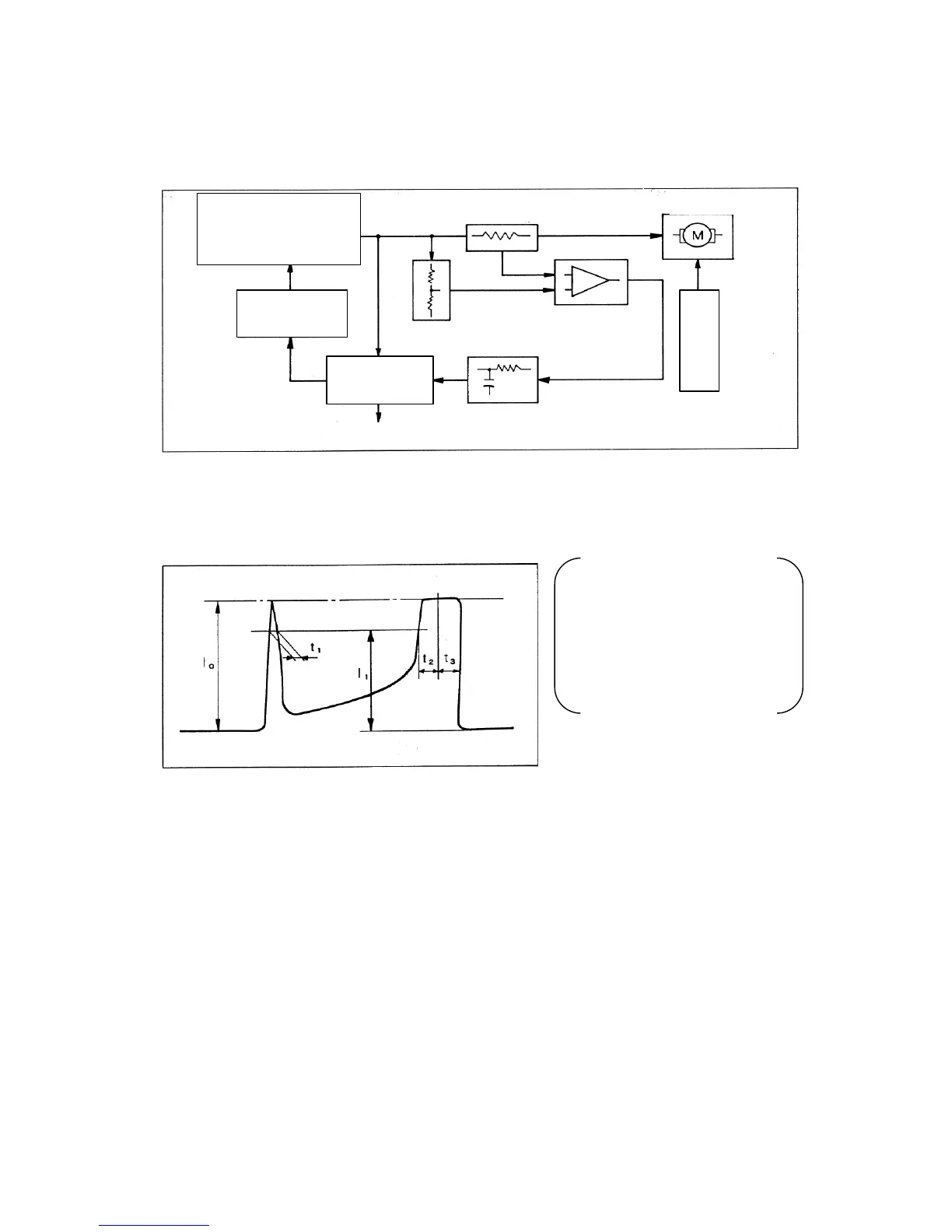

②Electric current waveform

③Movement principle

Load current value of motor goes up as screw is fastened. Controller compares this value with the

preset one, and when the two values coincides, controller stops motors a determined time later.

④Reference

・ Load current is proportionate to fastening torque since DC motor is used.

・

Not to stop motor with starting current, the follwing condition is adopted.

t1 < t2

・ Current detection level for I 1 is set to 75% of I 0.

I0:Motor starting current

I1:Detected current ( 0.75*10)

t1:Current delay time in I1

( 50ms as follows)

t2:Delay time(t2>t1)

t2+t3:Holding time(0.05~

Constant-voltage regulated

power supply circuit

( torque changeable)

Electric current Detector( Torque detection)

Loading...

Loading...