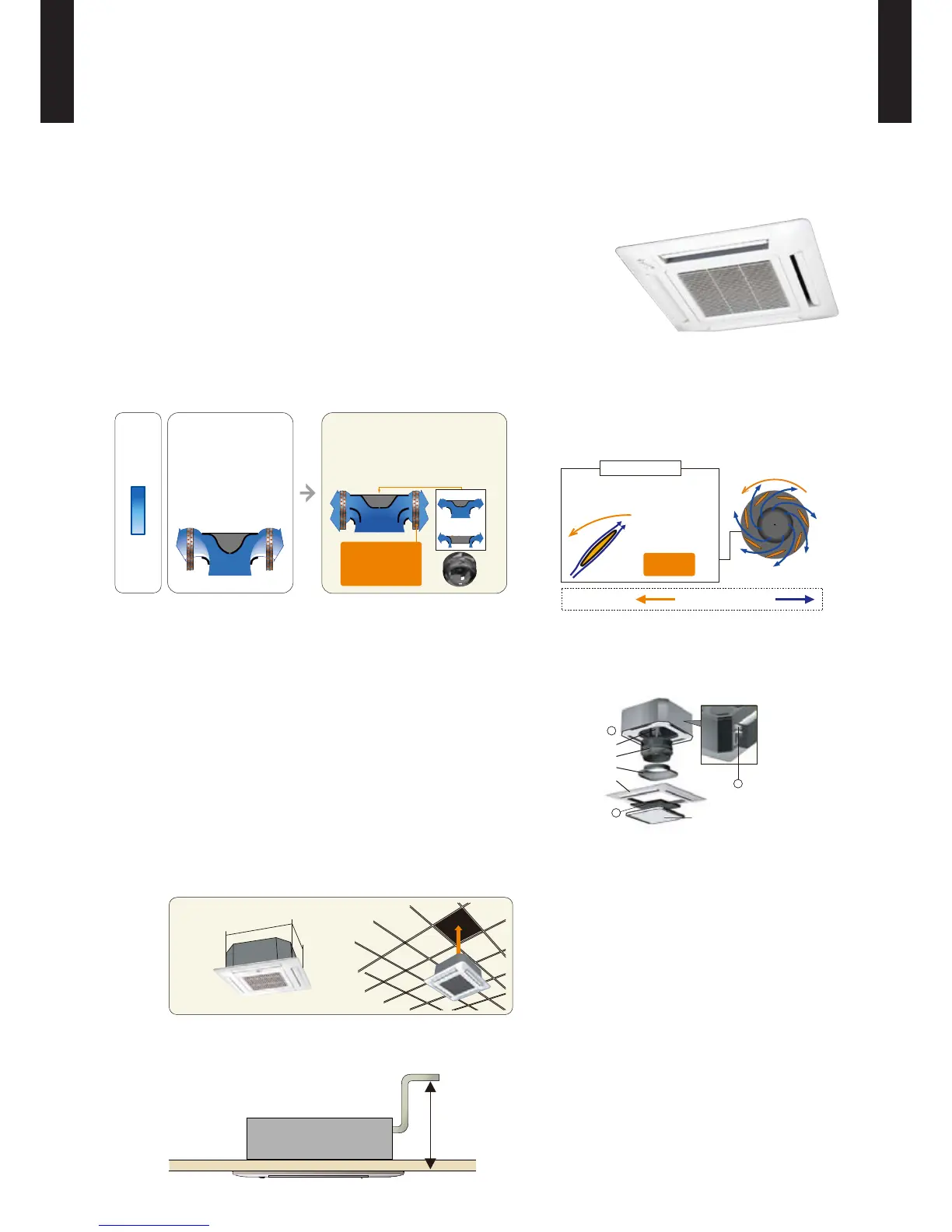

Previous turbo fan

In the case of a

conventional fan, the air

outlet range was narrow

as the airow moved to

the motor side which

meant the velocity of air

passing through the heat

exchanger was uneven.

2-stage turbo fan

A evenly spread air distribution across

the heat exchanger is possible due

to the new 2 stage turbo fan which

produces two separate airow

streams.

Heat exchange

efciency:

20%UP

1-stage

2-stage

Wind

velocity

Fast

Slow

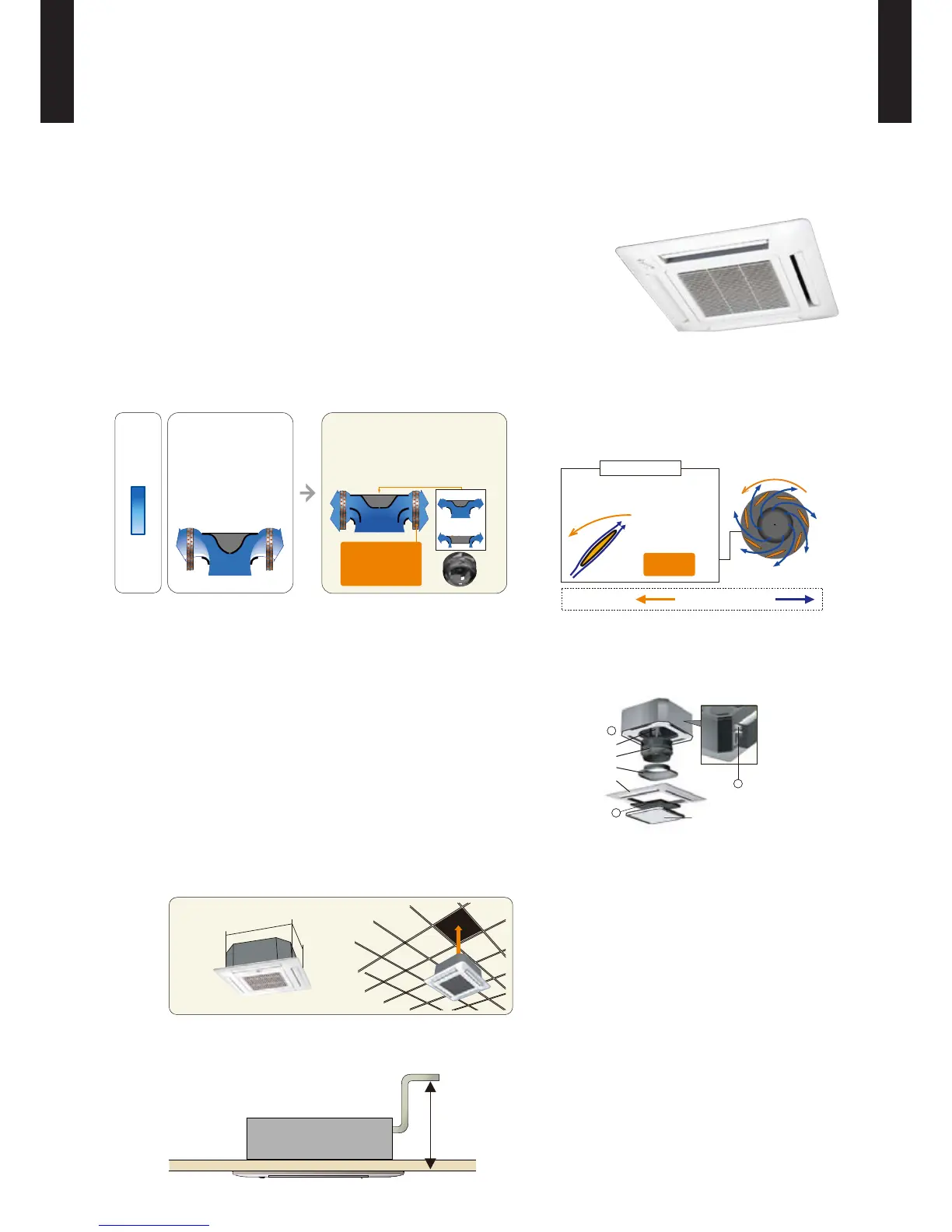

Easy maintenance

z

Maintenance of fan motor and fan

Maintenance of the fan motor and fan can be done easily after taking off the panel as the bell mouth of the fan

can be removed easily.

A : Fan motor B : 2-stage turbo fan

C : Bell-mouth D : Panel

Air lter

: standard equipment

Adaptation of transparent drainage parts

During installation, maintenance and operation, the drain pump and

kit can be checked easily.

Compact design

z

Easy installation by taking off ceiling panel of 600mm x 600mm size

Quiet quality

z

Optimization of wing form (laminar

wing type) and wing number (7 blades

each)

Airow runs through smoothly

along the laminar wing

No airow separation

Adoption of laminar wing

Spin direction

Airow direction

Quiet

Quiet

Designed by CFD-analysis (uid) simulations

Laminar wing

Loading...

Loading...