Fu nction

Code

Name

Settin g Range

Default

Value

F1. 24

En ergy Conservation

Selection

0: No O peration

1: Energ y Co nserv at ion

0

When the mot oris running in no-load or lower-loadduring,t he invertercan outputvoltage

by

adjust

automaticall y cur rent kf th e load。

Note:This function is especi ally valid for variable torque load (such as fan and pump).

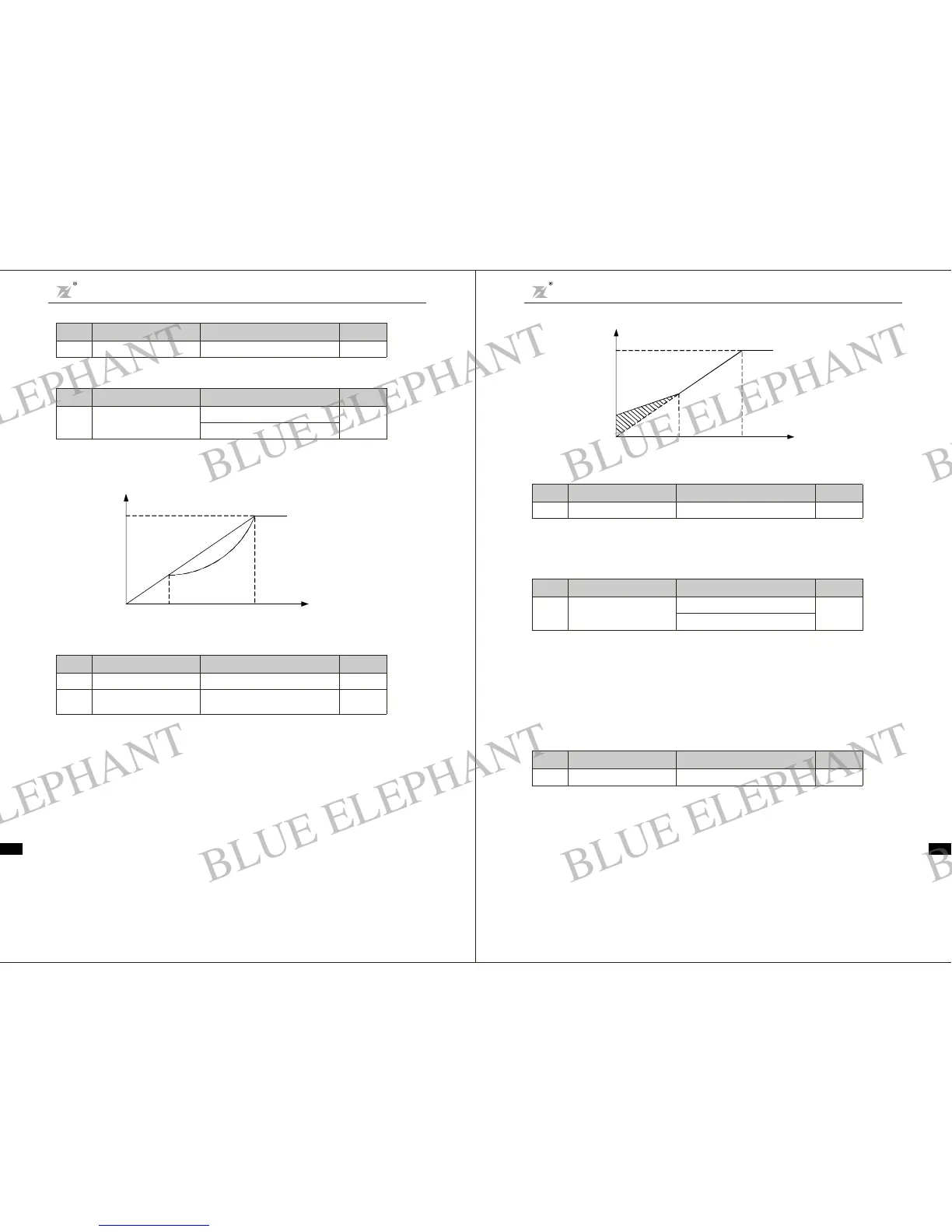

Fig. 6-7 Manual torque boost di agram

It sets up S1-S6,VI a ndCI terminal ssample filt eri ngtime. In big i nterference situati on, this parameter

should b e inc r ease d i n o r der to p r ev ent malo pera tio n .

O utp ut F requen cy f

Output Volta ge ( V)

f

cut -off

V

b oost

V

b

f

b

Setti ng this parametercan c ompensatet he motor spee dchange produced because of undertaking

l oading whi leon V/F control, to increase the rigidit y of motor mecha nica l performance. This value

should be set as the motor rated sli p frequency.

F 2 Inpu t and Output Termina l Fu nction Paramete rs

F1.2 3

V/F slip co mpensat ion limit

0. 0 20 0.0%

~

100 %

Fu nction

Code

Name

Settin g Range

Default

Value

F2.0 0

On-off signal filter t imes

110

~

5

Fu nction

Code

Name

Settin g Range

Default

Value

Chapter 6 Parameter D escripti on

DZB Series

-44-

Funct ion

Code

Nam e

SettingRange

Default

Valu e

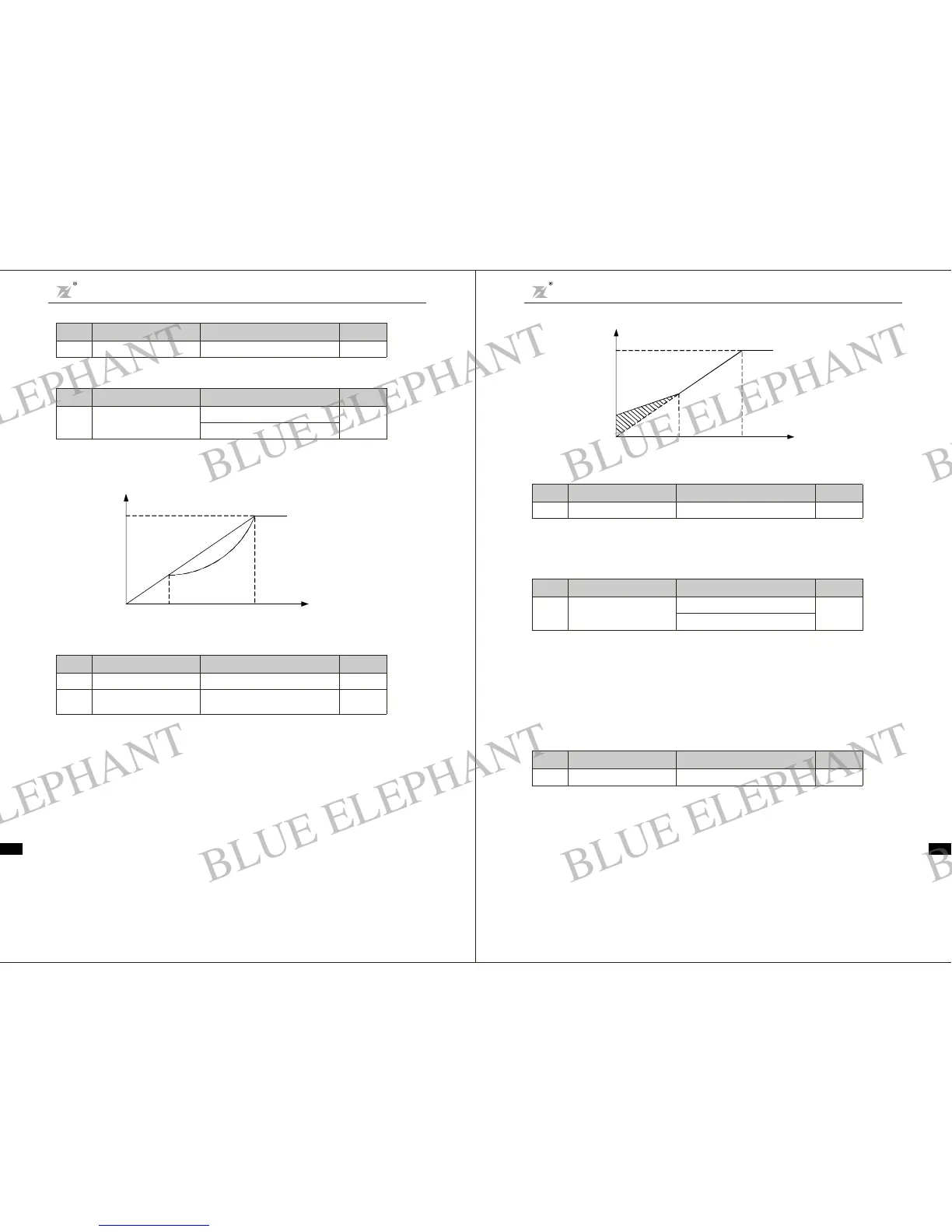

F1.20

V/Fc urve se tting

0 Lin ear V/F curve

:

1 square torqueV/F curve

:

0

The setting 100.0% iscorresponding to the rat ed output current.

0:LinearV/F c urve.It is applicable to constant torque l oad.

1:2.0 exponential V/F curve. It is ap plica ble tovar iable torque l oad, such as blower, pump etc.

Fig. 6-6 V /F curvediagram

Torque Bo ost is mainlyapplied to less than cut-offfrequenc y( F1.22).TheV/F curve after boost i s

shownin fol lowing figure . Torquebooth can improve thel ow frequency torque pe rformance ofV/Fc ontrol .

Ba sedon the load,a tor queshouldbe chosenproperly.F orheavyload, incr ea sethe tor que boost,but

the torque boost s hould no t be se t too big, whic h will result in the motor op erati ng a t ove rexcitat ion and

tha t itcould be overheated, and a lso t he inverter out put current is big, r educi ng efficiency.

Whenthe torque b oost is se t a s0.0%, the inverter is at automatic torqueboost.

Torque boos tcut-offfrequency: below this fre quency, torqueboost is valid, andabovet his frequency

se t ting , tor q ue boost is inv ali d .

b

f

b

V

b

f3/1

Output Voltage (V)

Output Frequency f

Linear V/F curv e

2.0 expo n entia l

V/Fc urve

F1.19

Upper torque lim it sett ing

0.0 200 .0%(invert er rated curre nt)~

150.0%

Funct ion

Code

Nam e

SettingRange

Default

Valu e

F1.21

Tor que boost 0.0% ( auto)

:

0.1 30 .0

%~ %

0

F1.22

Tor que boos t cu t-o ff

0.0% 50.0% (relative to motor

rated frequency)

~

20.0%

Funct ion

Code

Nam e

SettingRange

Default

Valu e

Chapter 6 Parameter Descr iption

DZB S eri es

-43-

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

Loading...

Loading...