Electric IOM

14

Electrical Requirements

1. Connect wiring as shown in the specific

wiring diagram which is furnished inside

the cover of the electrical control box. Be

sure to install a separate fused

disconnect for the boiler. All wiring must

conform to NEC Code.

WARNING

Prior to powering up the boiler, all electrical

contacts require re-torquing to the

individual compenents manufacturers

recommendations.

2. A correctly sized fused disconnect switch

should be fitted as close to the boiler as

possible and connections made to the

boiler control panel in compliance with

NFPA (National Fire Protection

Association), NEC Code, and local

codes. The appropriate number of

terminals are provided inside the control

panel box to take these connections, but

the panel box must be drilled to accept

the type of conduit used.

Boiler Controls

Fulton packaged electric steam boilers are

equipped with both a steam pressure

control and a high limit pressure control

mounted on the outside or inside of the

electrical panel box.

1. The steam pressure control should be

adjusted to suit the boiler application.

The control has two scales (main and

differential) which can be adjusted by

means of screws on top of the control.

The main scale setting should be

adjusted to the desired operating steam

pressure.

CAUTION

Do not adjust to exceed the pressure

rating on the boiler.

2. A high limit pressure control is located

next to the operating steam pressure

control and should be set 5 to 10 pounds

higher than the operating steam

pressure control. This control serves as

a secondary high pressure cut-off if for

some reason the main operating steam

pressure control should become

inoperative.

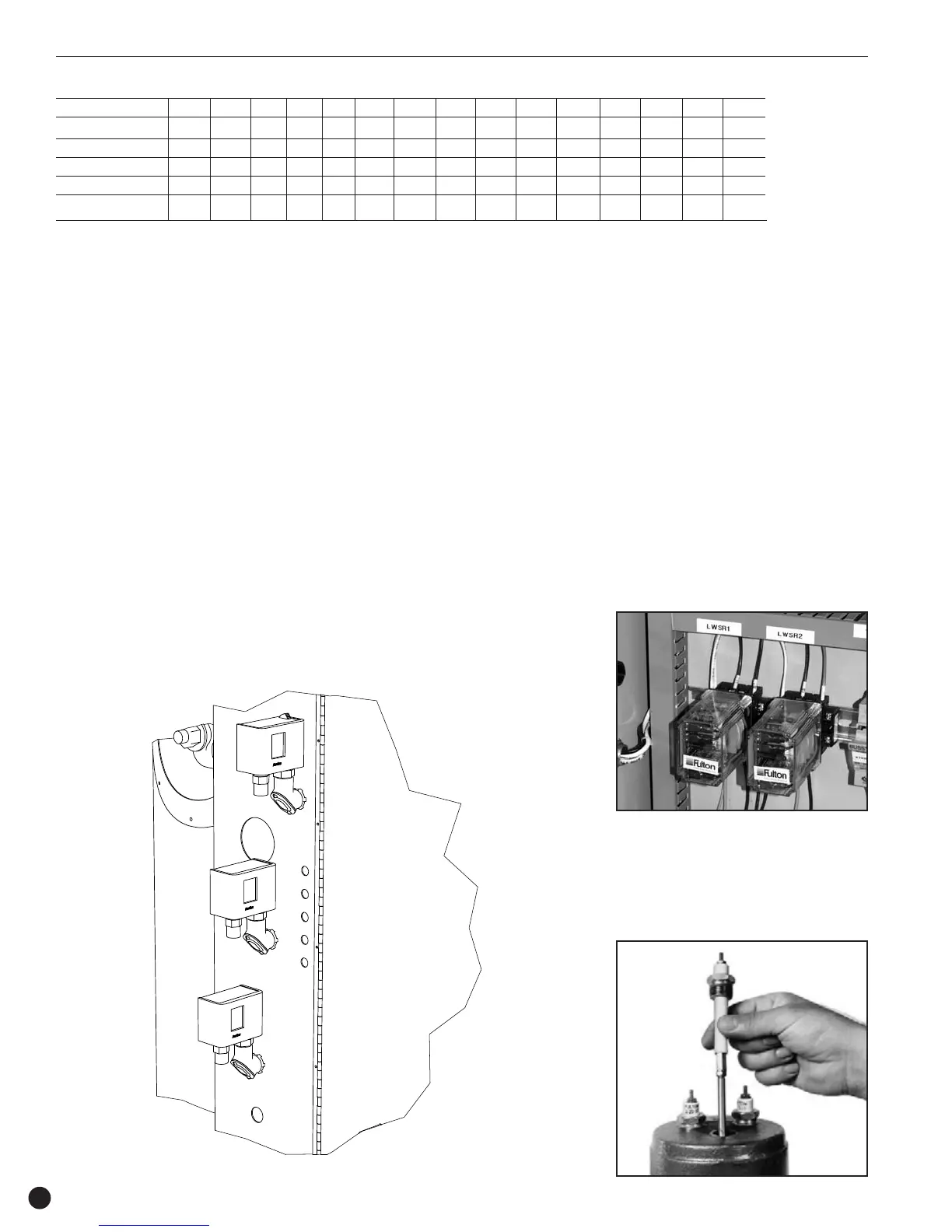

Low Water Control

Relays

1. Boilers from 1.2 to 3.6 HP are e quipped

with one low water cut off relay in the

panel box connected to two

independent probes in the top of the

boiler and one water level control relay

in the panel box operating two probes in

the top of the boiler.

2. Boilers from 5 - 20 HP contain two low

water cut off relays in the panel box

connected to two independent probes in

the top of the boiler.

3. Boilers from 30 - 100 HP have an

external water column on the right hand

side of the boiler. There are two low

water cut off control relays in the panel

box. One connects to a probe in the top

of the boiler and the other connects to a

probe in the top of the water bottle.

Installation

Electrical Power Requirements (In Amps)

Model FB-L 012 015 018 024 030 036 050 075 100 150 200 300 500 750 1000

208V 3 Phase 34 42 50 67 84 100 139 208 278 416 556 832 -- -- --

230V 1 Phase 52 65 78 -- -- -- -- -- -- -- -- -- -- -- --

230V 3 Phase 29 36 43 58 73 87 120 180 241 361 482 724 -- -- --

460V 3Phase 15 18 21 29 36 44 60 90 120 180 241 363 607 906 1204

575V 3 Phase 13 16 18 24 30 36 50 76 101 150 201 301 502 756 1004

Loading...

Loading...