RB-RBC-IOMM-2015-1

Fulton Ltd

Page 46

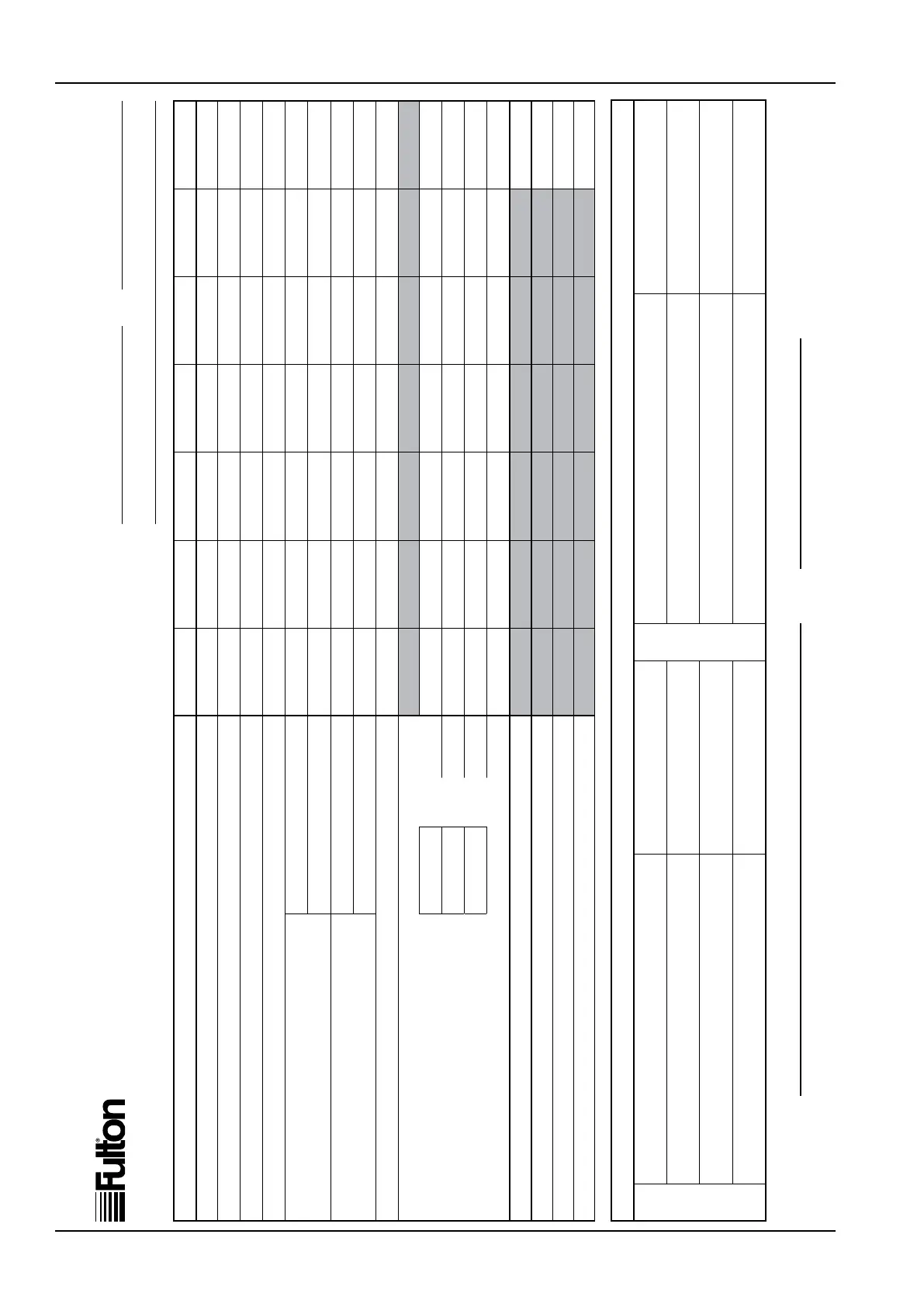

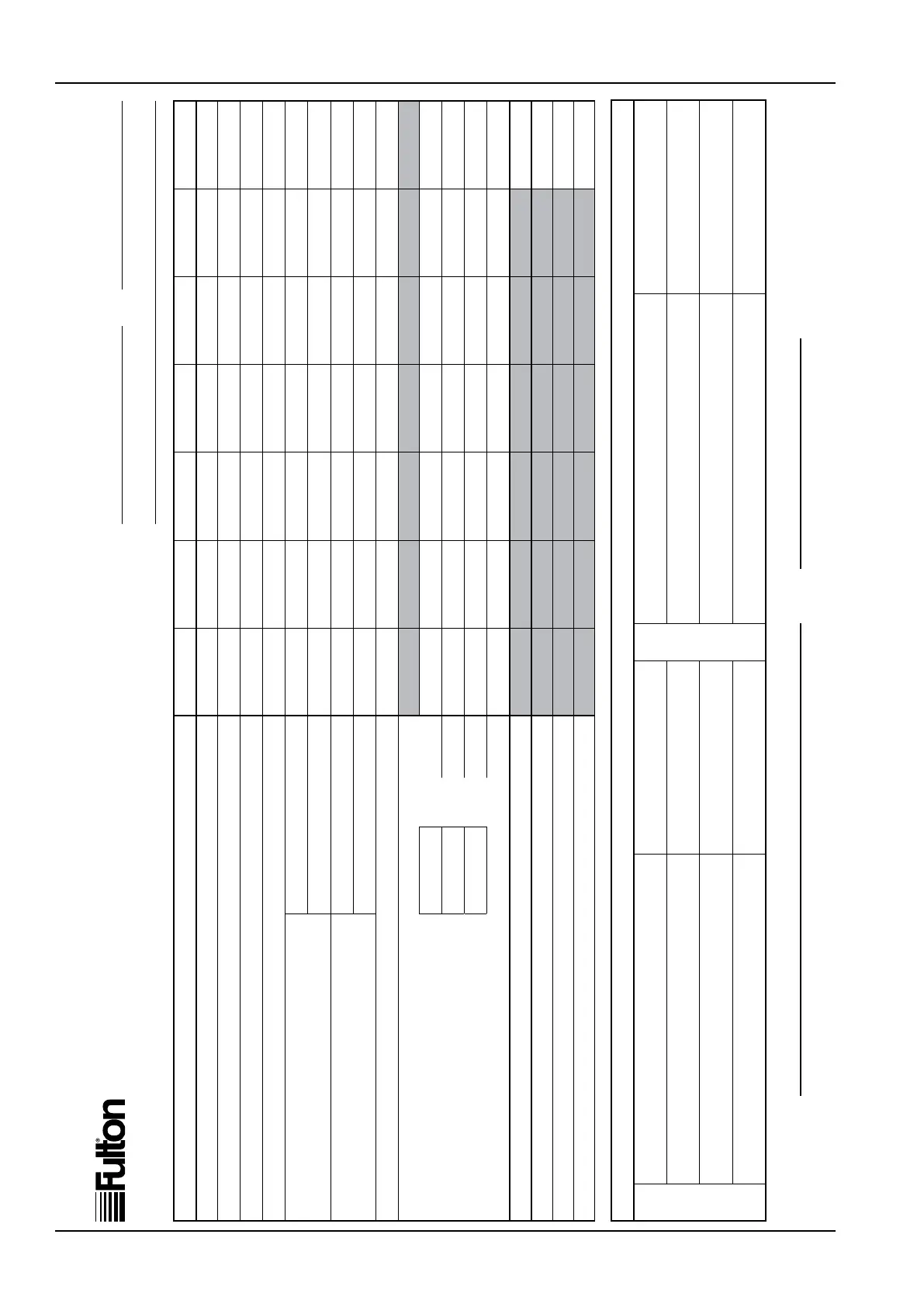

MAINTENANCE - 4

DAILY TESTS 1 2 3 4 5 6 7

Date

1.

V

isual Inspectionofpipework,ttingsandhandholesforsignsofleakage. Y - N Y - N Y - N Y - N Y - N Y - N Y - N

2.

1st Low W

ater Level Check - low water indicator illuminate, alarm sound and burner cuts-out. Y - N Y - N Y - N Y - N Y - N Y - N Y - N

3. 2nd Low Water Level Check - 2nd low water switch illuminates and alarm sounds. Y - N Y - N Y - N Y - N Y - N Y - N Y - N

4.

Blowdown, Boiler

Duration seconds.

T

est Time.

5.

Blowdown, W

ater Level Gauge

Duration seconds.

Test Time.

6.

Pressure gauge

reading for blowdown tests.

Boiler water and water treatment values must be within known tolerances of the datum.

7.

Boiler W

ater.

datum value. TDS. reading

datum value. PH reading

8.

Oxygen Scavenger Concentration datum value. reading

9.

Brine level correct Y -

N Y - N Y - N Y - N Y - N Y - N Y - N

WEEKLY TESTS 7+

10. Flame Sensor Test Y - N

11.

Feedwater Pump T

est - Feedwater pump, start/stop Y - N

12.

Safety valve outlet pipe

to safe blowdown point and free of damage Y - N

Test results and actions taken

Day 1. sig. Day 5. sig.

2. sig. 6. sig.

3. sig. 7. sig.

4. sig. 7+. sig.

Log examined by: Date:

Horizontal Steam Boiler - Daily and Weekly Tests

Model:

Fuel:

Boiler Number:

Loading...

Loading...