Do you have a question about the Gardner Denver Reavell H5000 Series and is the answer not in the manual?

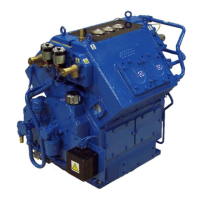

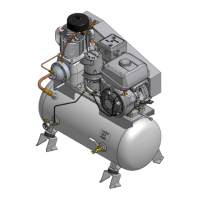

| Brand | Gardner Denver |

|---|---|

| Model | Reavell H5000 Series |

| Category | Air Compressor |

| Language | English |

Details for recording compressor ownership information.

Introduction to the handbook and compressor.

Guidance on maintenance procedures and requirements.

Information regarding the warranty terms and conditions.

Important warnings and advisories for safe operation.

Guidelines for environmentally sound disposal of waste.

Essential precautions for safe operation and maintenance.

Procedures for purging gas installations before operation.

Guidelines for operating in hazardous environments.

Records of changes made to the manual.

Describes the compressor's physical layout and design.

Details on the lubrication system and recommended lubricants.

Advantages and disadvantages of synthetic oils.

Explanation of the compressor's cooling system.

Information on the compressor's drive system.

Specifies the model and designation of the unit.

General specifications including type, cooling, and mounting.

Operating temperature ranges for ambient and working fluids.

Specifies minimum and maximum operating speeds.

Details maximum and minimum working pressures.

Key internal measurements of the compressor components.

Oil capacity and recommended lubricants.

Cooling water flow rate and temperature specifications.

Specifies sizes for various pipe connections.

Permissible clearances for moving parts during operation.

Torque values for assembly operations.

Instructions for safe lifting and moving the compressor.

Recommended site selection and environmental considerations.

Guidance on securing the compressor to its foundation.

Requirements for system and pipework layout and installation.

Advice on drive arrangements, belts, and alignment.

Detailed instructions for the cooling system setup and operation.

Requirements for electrical installation and safety compliance.

List of recommended supporting equipment for the installation.

Checks and preparations before the initial run.

Step-by-step guide for starting the compressor.

General guidelines for operation and routine checks.

Procedures for safely starting the compressor.

How to operate the compressor when under load.

Correct procedure for stopping the compressor.

Procedures for periods when the compressor is not in use.

Importance of recording maintenance logs.

Daily checks for oil level, pressure, and temperature.

Weekly checks for leaks, oil condition, and controls.

Specific maintenance after initial mineral oil run.

Steps for transitioning to synthetic lubricants.

Scheduled maintenance tasks based on operating hours.

General advice on valve maintenance.

Procedures for cleaning and inspecting valve components.

Steps for safely removing and taking apart valves.

How to clean individual valve components.

Instructions for replacing valve assemblies.

Detailed steps for reassembling valves.

Troubleshooting steps for a compressor that won't start.

Diagnosing and resolving issues causing start-up shutdowns.

Identifying causes and solutions for reduced compressor output.

Troubleshooting for safety valves activating unexpectedly.

Addressing faults causing the compressor to stop abruptly.

Investigating reasons for excessive oil usage.

Troubleshooting low oil pressure faults.

Diagnosing and resolving compressor overheating issues.

Identifying sources of abnormal noise during operation.

Identifying sources of abnormal noise when unloaded.

Instructions and required information for ordering spare parts.

List and diagrams of parts for the crankcase assembly.

List and diagrams of parts for the running gear assembly.

List and diagrams of parts for the first stage cylinder.

List and diagrams of parts for the second stage cylinder.

List and diagrams of parts for the cooler assemblies.

List and diagrams of parts for pressure gauges.

List and diagrams of parts related to the lubrication system.

List and diagrams of parts for drain valves and associated piping.

List and diagrams of external components.

List and diagrams of parts related to the drive system.

List and diagrams of parts for the 1st stage concentric valve.

List and diagrams of parts for the 2nd stage concentric valve.

List and diagrams of parts for diaphragm drain valves.

Lists various joint kits available for assembly and maintenance.

Lists available 'O' ring kits for different components.

Lists kits for valve maintenance.

Details and settings for the temperature controller.

Installation, operation, and testing of safety valves.

Information on the 3-way solenoid valve used in DDVs.

Details on anti-vibration mount types and maintenance.

Information and parts for the water pump drive assembly.

Special instructions for filling the compressor's cooling system.

General information, installation, and service of pressure gauges.

Guidelines for preventive maintenance and installation of flexible hoses.

Identifies terminal numbers for set wiring connections.

Loading...

Loading...