Page 13

Troubleshooting 3D Models

Machine Maintenance

Dust and Debris

The gMax was designed with robust components however all machines are susceptible to dust and

debris causing performance issues especially if the electronics are not

getting proper cooling.

We recommend blowing out the fans on the power supply, inside the

electronics case and on the extruder often.

Make sure to clear loose filament or debris from the belts, pulleys, and

guide rails. Also make sure to use the supplied metal bristle brush to

clean filament off the nozzle when it is hot

Lubricating linear rails

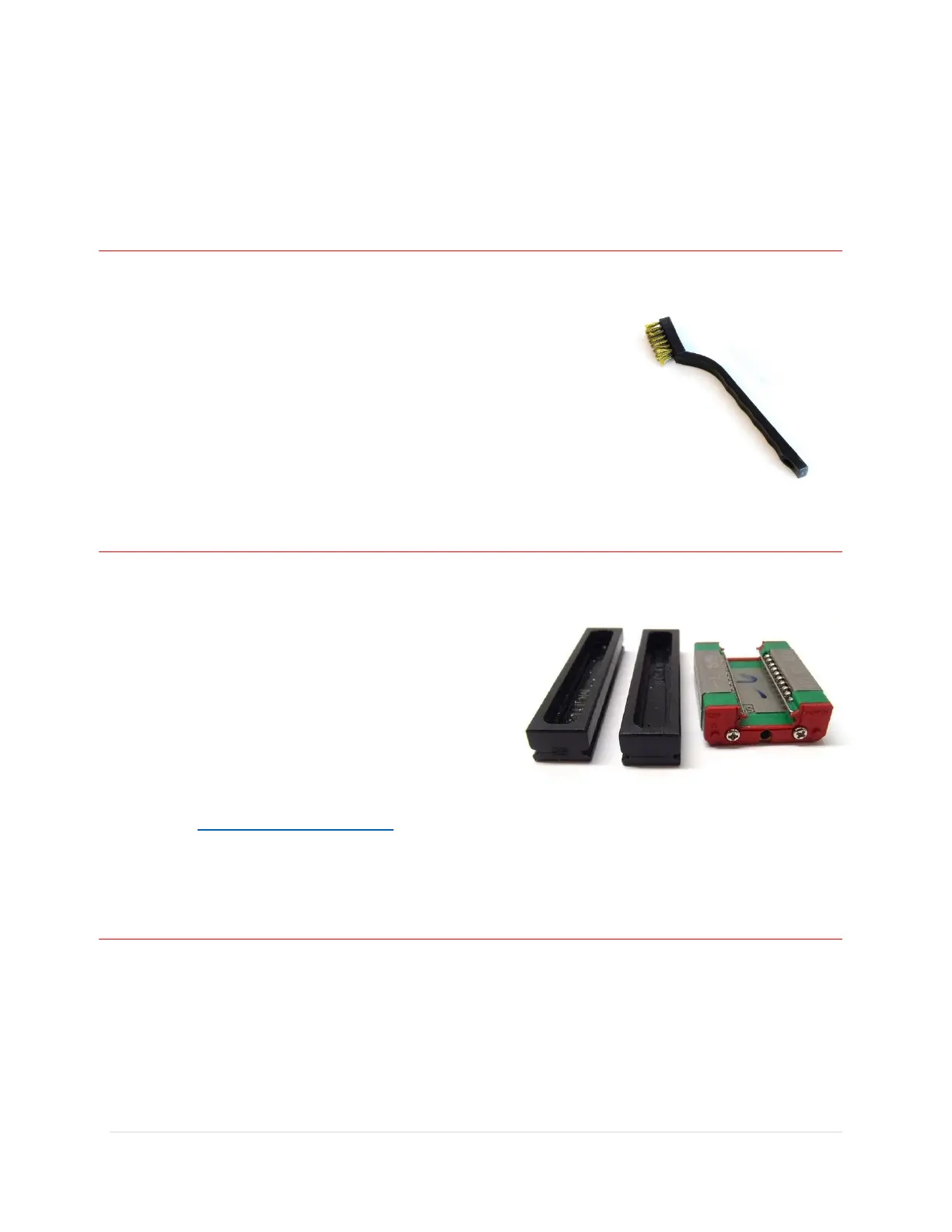

The gMax 2 Pro uses Hiwin linear guide rails and blocks. The guide blocks contain rows of recirculating

ball bearings and it performs best when lubricaled and clear of debris.

The X and Z axis use Hiwin MGN15C rails and the Y axis

uses EGH15C rails.

Warning. Do not remove the linear block from the rail

without the use of a plastic stopper or you risk having

the ball bearings fall out and ruin the block.

To clean and lubricate the rails we recommend wiping

them clean with a paper towel and spraying with

CorrosionX (http://www.corrosionx.com) ensuring the

lubricant gets inside the bearings.

Tightening or replacing belts

The gMax printer uses 6mm wide GT2 fiber reinforced timing belts. Use the guide below to replace or

tighten the belts. Do not use metal reinforced belts as the tight radius of the pulleys will weaken the

metal fibers over time causing the belt to break.

Loading...

Loading...