11-2

Data subject to change without notice 7/07. © 2007 GE Drives

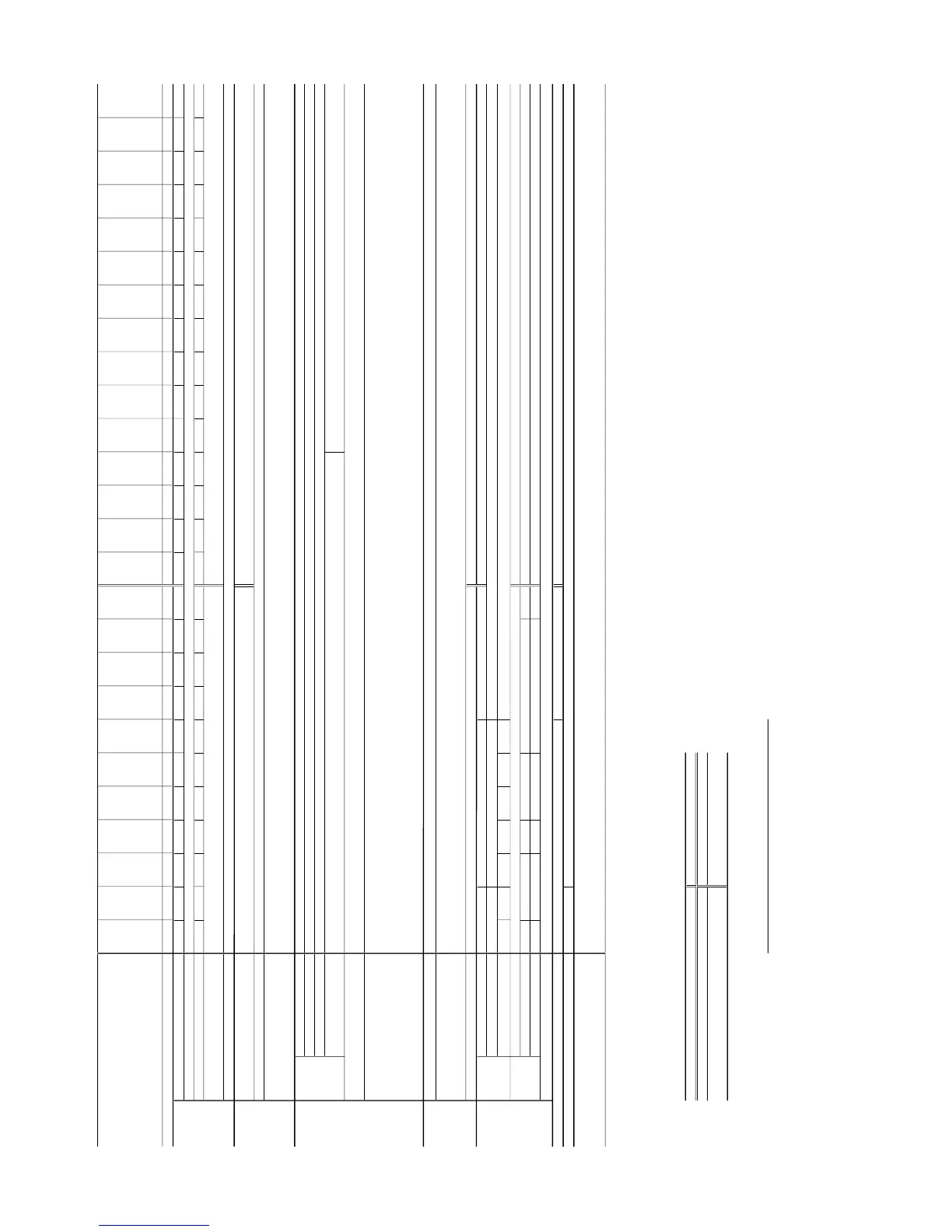

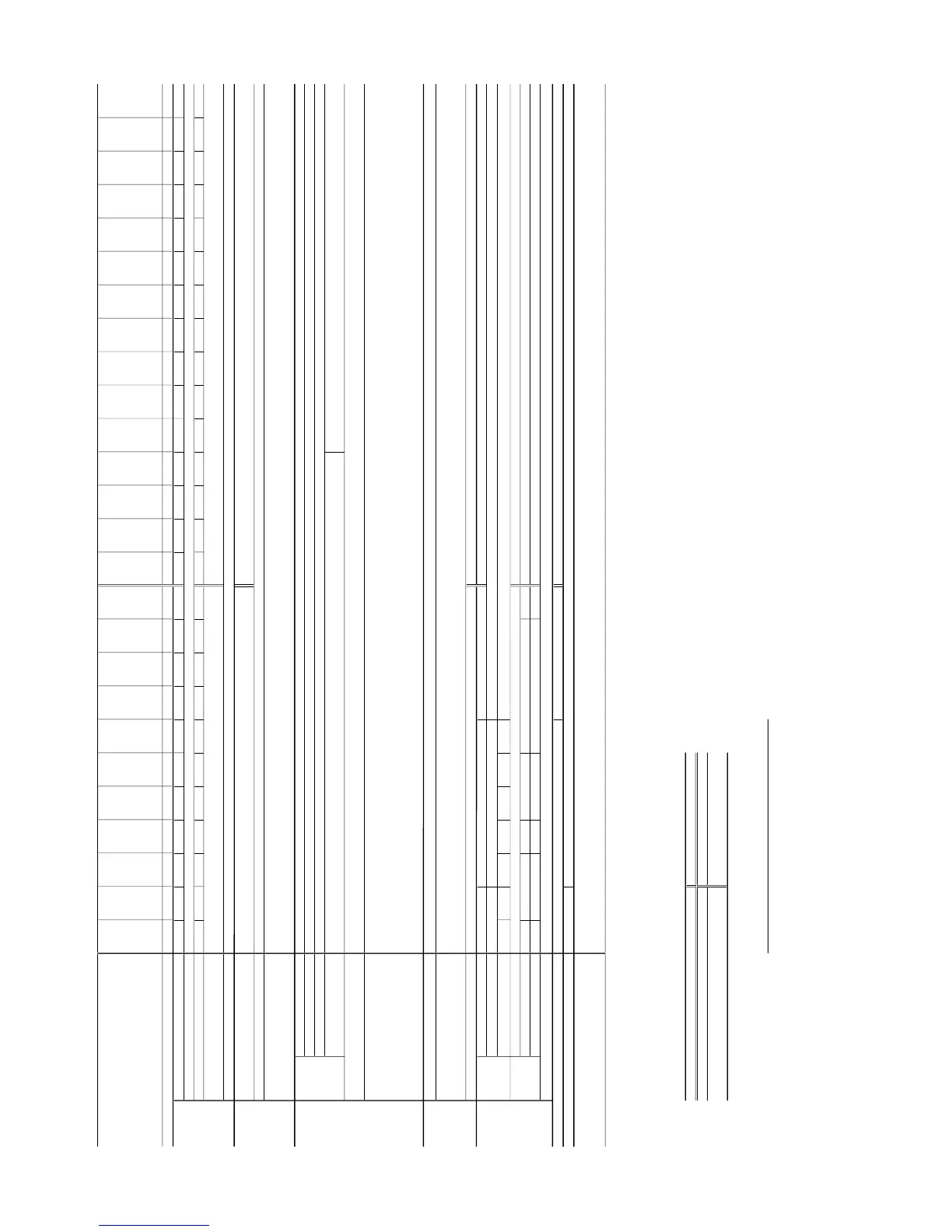

Three-phase 460V series

F50 001 002 003 005 007 010 015 020 025 030 040 050 060 075 100 125 150 200 250 300 350 400 450 500 600

Norminal 460V system applied motor HP 1/2 12357.5101520253040506075100125150200250300350400450500600

Rated Capacity *1) kVA 1.1 1.9 2.9 4.3 7.1 10 14 19 23 31 35 47 59 72 89 119 140 167 201 242 300 330 414

466 518 590

Rated Voltage *2) V 3-phase, 380V , 400V , 415V /50Hz , 380V , 400V , 440V , 460V /60Hz

Rated Current *3) A 1.5 2.5 3.7 5.5 9.0 13 18 24 30 39 45 60 75 91 112 150 176 210 253 304 377 415 520 585 650 740

Overload Capability 150% of rated current for 1min , 150% of rated current for 1min ,

200% of rated current for 0.5s 180% of rated current for 0.5s

Rated Frequency Hz 50, 60Hz

Input Phases, Voltage, Frequency 3-phase, 380 to 480V , 50/60Hz 3-phase, 380 to 440V /50Hz , 380 to 480V /60Hz

ratings * 380V/50Hz and 380 to 415V/60Hz *4)

Voltage / frequency variations -Voltage : +10 to -15% ( Voltage unbalance *5) : 2% or less ) -Frequency :+5 to -5%

Momentary voltage dip When the input voltage is 310V or more, the inverter can be operated continuously.

capability *6) When the input voltage drops below 310V from rated voltage, the inverter can be operated for 15ms . (less th

an 85% load of nominal applied motors)

The smooth recovery method is selectable.

Output Maximum Freq. 50 to 400Hz *10)

frequency Base Freq. 25 to 400Hz *10)

Setting Starting Freq. 0.1 to 60Hz , Continuous time : 0.0 to 10.0s

Carrier Freq. *8) 0.75 to 15kHz 0.75 to 10kHz

The minimum carrier frequency changes depend on maximum output frequency.

Accuracy (Stability) -Analog setting : ±0.2% of Maximum frequency (at 25 ±10 degrees C)

-Digital setting : ±0.01% of Maximum frequency (at -10 to +50 degrees C)

Setting resolution -Analog setting : 1/3000 of Max. frequency ex.) 0.02Hz at 60Hz , 0.15Hz at 400Hz

-Digital setting : 0.01Hz at Maximum frequency of up to 99.99Hz (0.1Hz at Maximum frequency of 100Hz and above)

-Link setting

: Two methods are selectable.

Control Volt/Freq Characteristic 320 to 480V (with AVR control) at base and maximum frequency, adjustable

Torque boost Constant toruque load Variable torque load

Automatic (setting code) 0.0 -

Manual (setting code) 2.0 to 20.0 0.1 to 1.9 *9)

Starting torque 200% (with Dynamic torque vector control selected) 180% (with Dynamic torque vector control selected)

Braking Braking torque 150% 100% 20% *11) 15 to 10% *11)

Standards Time s 5 5 No limit

Duty cycle % 5353232 No limit

Braking torque 150% 100%

Options Time s 45 45 30 20 10 8 10

Duty cycle % 22 10 7 5 5 5 10

DC injection braking Starting frequency : 0.1 to 60.0Hz , Braking time : 0.0 to 30.0s, Braking level : 0 to 100% of rated current

Enclosure NEMA Type1, Type 4 NEMA Type1, Type12 Open, Open with NEMA Type 12 Heatsink, NEMA Type 1

Cooling method Natural Fan cooling

Standards -UL/cUL

NOTES

*1) Inverter output capacity [kVA] at 460V.

*2) Output voltage is proportional to the power supply voltage and can't exceed the power supply voltage.

*3) Current derating may be required in case of low impedance load such as high frequency motor.

*4) Change the tap of auxiliary transformer.

380V/50Hz and 380 to 415V/60Hz : Change over CN UX connector from U1 part to U2 part. (Reference to the Instruction manua

l)

Input voltage

CN UX connector

400 to 440V/50Hz, 440 to 480V/60Hz

U1 (Factory setting)

380V/50Hz (398V or smaller),

380 to 415V/60Hz (430V or smaller)

*5) Reference to the IEC 61800-3( 5.2.3 )

(Maximum voltage[V] - Minimum voltage[V] )

3-phase averaging voltageV

*6) Input power : 85%

*8) If carrier frequency is set at more than 10kHz and an overheat condition (detected by internal thermal sensor ) occurs, i

nverter will automatically reduce carrier frequency to 8kHz ,

in order to avoid trip.(Available up to 30HP unit)

*9) When setting into 0.1, the starting torque gets 50%

*10) Above 120Hz application, please contact the factory

*11) With a nominal applied motor.(Average torque when the motor decelerates and stops from 60Hz. It may change according to t

he motor loss.)

-LOW VOLTAGE directive -IEC 61800-2 Rating,

specifications for low voltage adjustable frequency a.c.

power drive systems)

-EMC directive -IEC 61800-3 (EMC product

standard including specific test methods)

1/20000 of Maximum frequency ex.) 0.003Hz at 60Hz , 0.01Hz at 400Hz

0.01Hz (Fixed)

Unbalance in power supply voltage [%] =

Type designation ( * * indicate product revision)

6KP1143_ _ _X1 * * (NEMA Type1)

6KP1143_ _ _ X2 * * (NEMA Type12)

6KP1143_ _ _ X4 * * (NEMA Type 4)

6KP1143_ _ _ X8 * * (Open, Type 12 Heatsink)

6KP1143_ _ _ X9 * * (Open)

Loading...

Loading...