GE HEALTHCARE

DIRECTION 5394227, 12 LOGIQ S8/LOGIQ E8 SERVICE MANUAL

Section 9-4 - Maintenance task schedule 9 - 3

Section 9-4

Maintenance task schedule

9-4-1 How often should maintenance tasks be performed?

The Care & Maintenance task schedule (Table 9-1 below) specifies how often your LOGIQ™ S8 should

be serviced and outlines items requiring special attention.

NOTE: It is the customer’s responsibility to ensure the LOGIQ™ S8 care & maintenance is performed

as scheduled in order to retain its high level of safety, dependability and performance.

Your GE Service Representative has an in-depth knowledge of your LOGIQ™ S8 ultrasound scanning

system and can best provide competent, efficient service. Please contact us for coverage information

and/or price for service.

The service procedures and recommended intervals shown in the Care & Maintenance Task Schedule

assumes that you use your LOGIQ™ S8 for an average patient load (10-12 per day) and not use it as

a primary mobile unit which is transported between diagnostic facilities.

NOTE: If conditions exist which exceed typical usage and patient load, then it is recommended to

increase the periodic maintenance frequencies.

Abbreviations used in the Customer Care Schedule 9-1:

D = Daily W = Weekly M = Monthly A = Annually

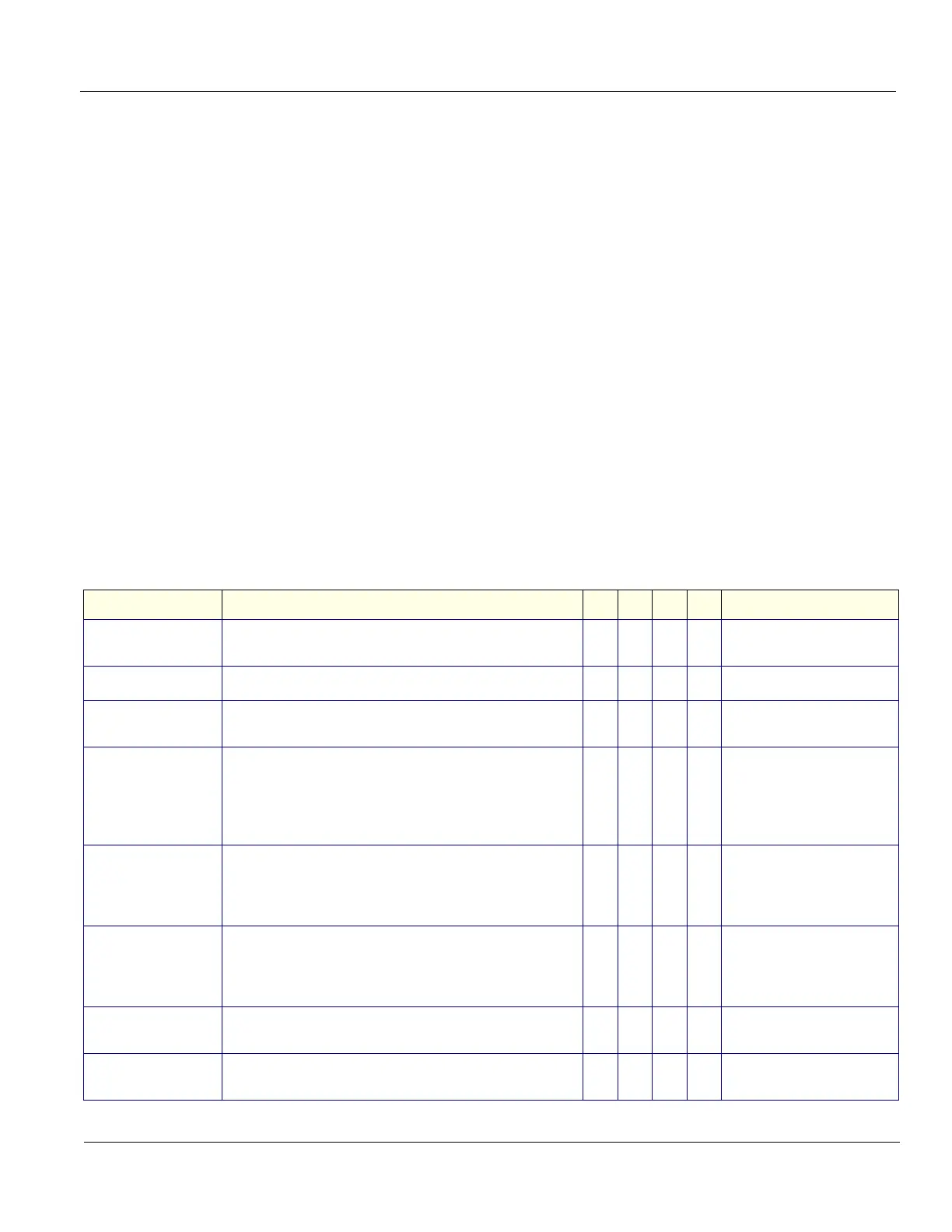

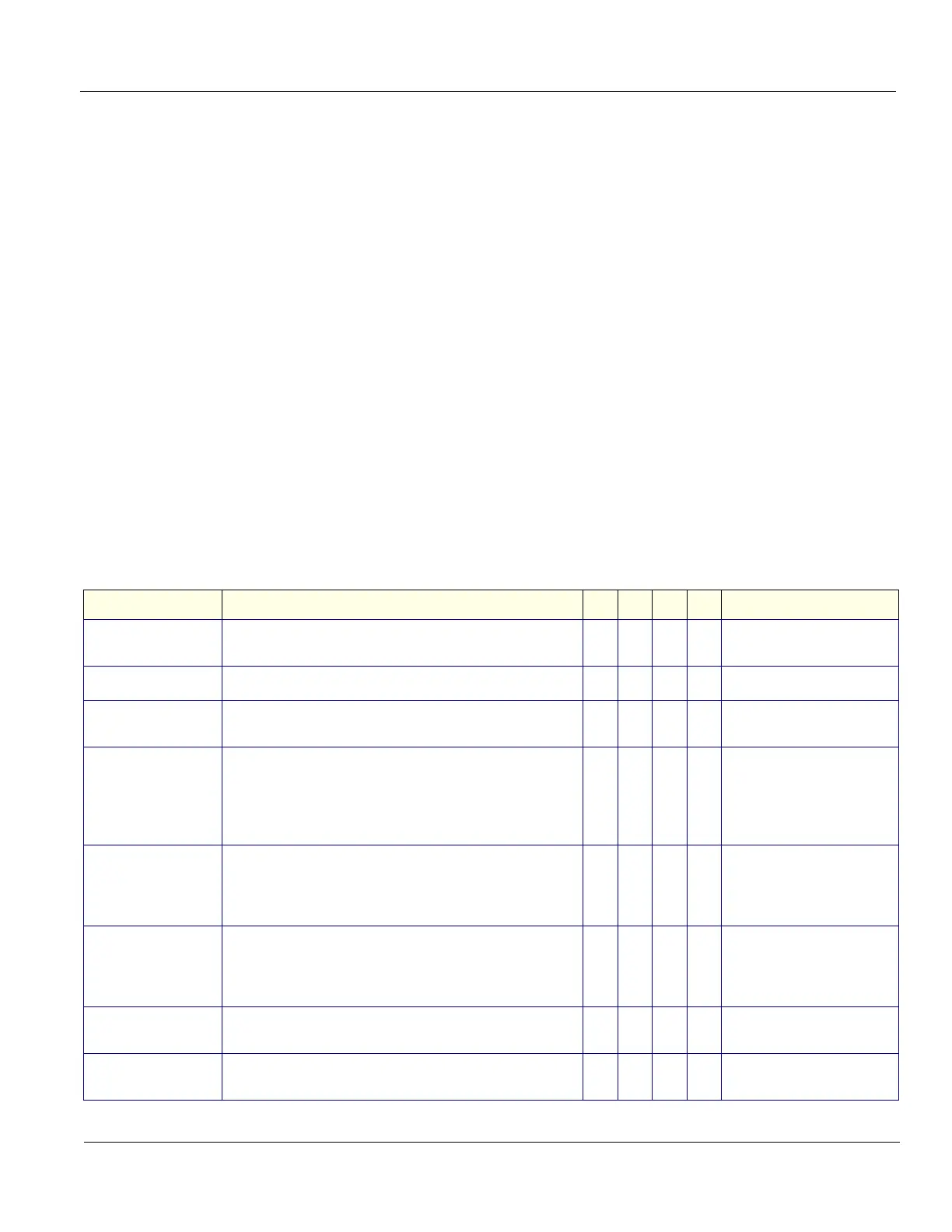

Table 9-1 Customer Care Schedule

Item Service at Indicated Time D W M A Notes

Air Filter Grid Remove the filter grid and clean the air filter.

•

Recommend to clean filter

at least bi-weekly

AC Mains Cable Inspect AC Mains Cable

•

Mobile Unit Check weekly

Cables and

Connectors

Check if all cables are fixed well seated at the correct

position and if there is no mechanical damage visible.

•

also after corrective

maintenance

User Interface

Clean alphanumerical keyboard, Functional keys, Digital

potentiometers, TGC-Shift potentiometers. (vacuum

cleaner, lukewarm soap water on a soft, damp cloth)

•

Be careful not to get the

cloth too wet so that

moisture does not enter

the loudspeakers, TGC-

Slider, or other keys!

LCD Monitor, Touch

Panel and Probe

holder

Clean LCD Monitor surface and Probe holder with a fluid

detergent in warm water on a soft, damp cloth.

•

Be careful not to get the

cloth too wet so that

moisture does not enter

the entire system.

Mechanical parts

Clean and inspect the mechanical function of wheels,

casters, brakes and swivel locks as well as side door, foot

rest, front and rear handle, and monitor holder.

Remove Dust and Coupling gel.

•

Mobile Unit Check Daily

Control Console

movement

Check Translation/Rotation and Height Adjustment

(Elevation)

•

more frequently at Mobile

Units

Trackball Check

Check proper operation

(Cursor movement X, Y direction)

•

If failure occurs go to

trackball cleaning.

Loading...

Loading...