Chapter 3 System Setup Page: 79 Setup Warnings Lists critical warnings and safety precautions to observe during system setup.

Connecting Probes Provides instructions and precautions for connecting ultrasound probes.

Power ON Describes the steps for powering on the system and what to expect during the boot process.

Login Explains the login process and user acknowledgment of regulations.

Password Policies Describes how to create and set password policies for system access.

Disk Encryption Explains how to enable and manage disk encryption for data security.

ECG Connector Shows the location of the ECG connector on different system versions.

Stand-alone LOGIQ S8 Describes the setup for a stand-alone LOGIQ S8 scanner without network connection.

Network Icon Explains the meaning of network icons displayed on the system.

TCPIP Details how to configure TCP/IP settings for system and network connectivity.

Device Explains how to add, manage, and ping connected devices.

Service Details how to add and configure services for destination devices.

User Manual(s) Advises to check for correct User Manuals and their language versions.

Chapter 4 Functional Checks Page: 177 Power ON Details the procedure for powering on the system.

Login Explains the login procedure and user acknowledgment.

Caster Describes how to lock and unlock the swivel/brake casters.

Moving the System Details the procedure for physically moving the system, including safety checks.

Overview Introduces the functional checks for the LOGIQ S8 and their purpose.

Preparation Outlines initial steps required before performing functional checks.

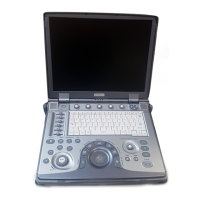

Basic Controls Provides a labeled diagram of the system's control panel.

Trackball Area Explains the functions and usage of the trackball and its associated controls.

B-Mode Checks Details the steps and controls used to optimize and verify B-Mode image quality.

M-Mode Checks Outlines preparations for M-Mode checks, including phantom use and scanner setup.

Basic Measurements Guides on performing distance, tissue depth, and circumference/area measurements.

DVD Drive Test Guides on testing the DVD drive's read/write capabilities.

LAN Port Test Outlines how to test the LAN port for network recognition.

To Connect a Probe Provides instructions for safely connecting probes, including handling precautions.

ECG Check Explains ECG capability and how to perform checks using cables or a simulator.

Peripheral Checks Checks the functionality of various peripherals like DVR, printers, and media drives.

Single CWD Guides on testing the Continuous Wave Doppler (CW) function.

Label Check Details how to check for the presence and condition of system labels on R1-R3 models.

3 D;4 D (Option) Details how to test the 3D/4D option, including probe preparation.

Chapter 7 Diagnostics;Troubleshooting Page: 271 Section 7-1 Overview Describes tools and software for maintaining image quality and system operation, including diagnostics.

Error Logs Explains how to view and interpret system error logs using the Log Viewer.

Diagnostics Details how to perform common service components and diagnostics tests.

Image Quality Explains how to verify image quality within the system.

Configuration Provides information on viewing and modifying device information and configurations.

Disruptive Mode Explains how to control interruptions to operation using Disruptive Mode.

Licenses Lists available options with Service Basic Access, including HOME and Utilities.

Home Explains how home configurations vary depending on the purchased service level.

Software Status Provides information about the installed software versions and application status.

Connected Probes Shows information about probes connected to the LOGIQ S8, including status and serial numbers.

Utilities Lists various utility configurations and related information.

Change Password Allows changing the password for specified user types, with data loss warnings.

Data Transfer Provides methods for viewing and setting up automatic or manual data file transfers.

Delete Files Explains how to delete files and folders from the D:\Service directory.

Gather Logs Utility Provides a way to collect system logs and place them in the D:\Service directory.

Network Capture Displays network traffic and provides tools to capture network logs for analysis.

SSA License Provides functionality to view SSA key details, status, and restore licenses.

Options Allows viewing and managing software options and their details.

Chapter 9 Care & Maintenance Page: 375 Warnings Provides essential safety warnings for system maintenance.

Why Do Maintenance Explains the importance of maintaining records and quality assurance programs.

Tools Required Lists special tools, supplies, and equipment needed for periodic maintenance.

Functional Checks Details system functional checks for B-Mode, Color Flow, Doppler, and other modes.

Cleaning Provides guidelines for general cleaning and appropriate disinfectant agents.

Air Filter Cleaning Details the procedure for cleaning the system's air filters to prevent overheating.

Physical Inspection Instructs to check the system exterior for loose or cracked parts and labels.

Probe maintenance Provides guidance on probe care, handling, and cleaning to prevent damage.

Mains on Applied Part Tests sink leakage current by applying mains voltage to the probe's insulation barrier.

Chassis Fails Troubleshooting steps for chassis failures related to grounding and connections.

Probe Fails Guides on isolating probe failures by testing with different probes.

Peripheral Fails Troubleshooting steps for peripheral failures, focusing on grounds and connections.

Still Fails Provides isolation steps by removing peripherals to monitor leakage current.

ECG Fails Instructs to inspect ECG cables for damage or poor connections.