14

09665-08.2018-Gb

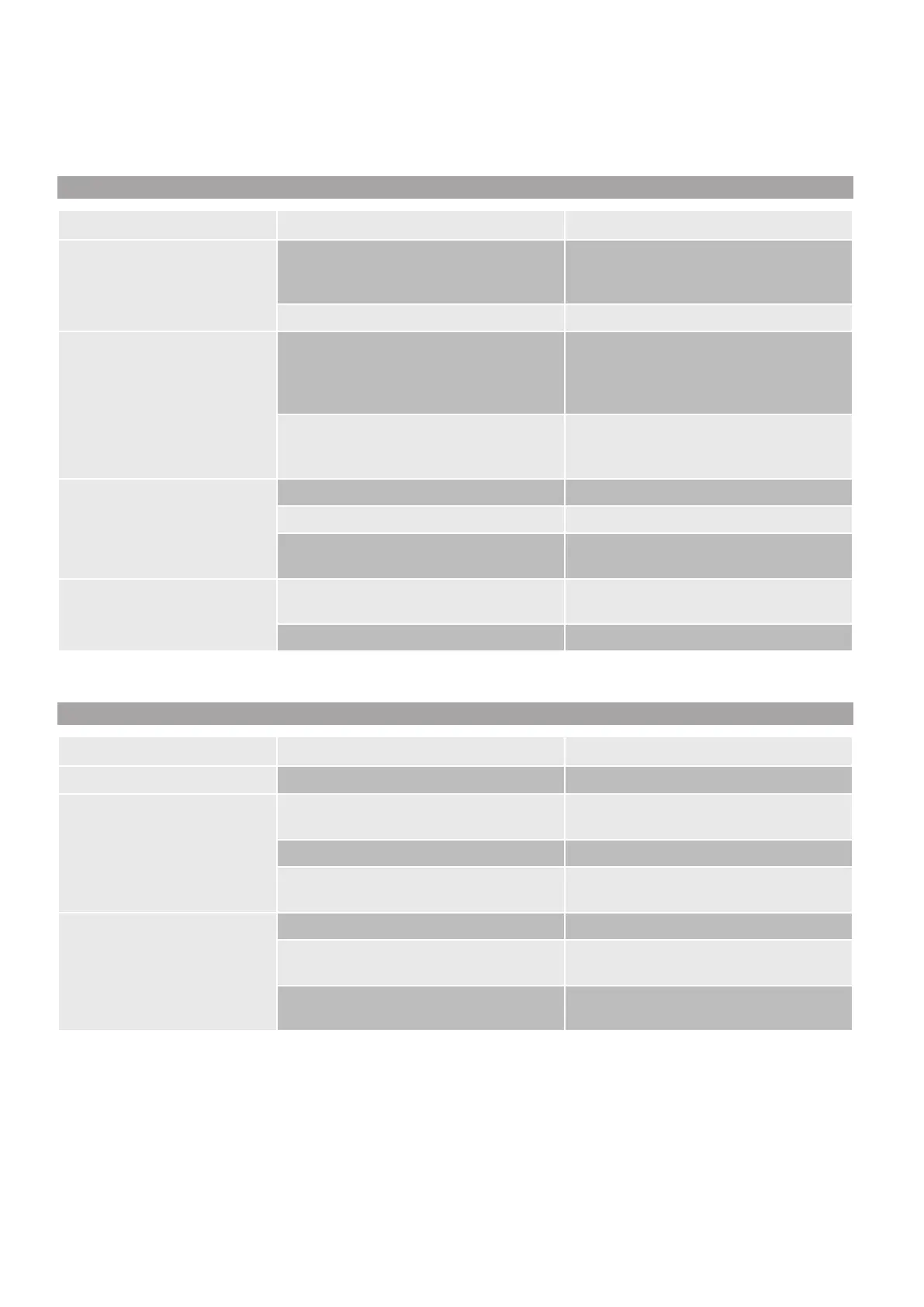

6 I Fault diagnosis

Abnormal running noise from compressor

Problem Possible cause Remedy

Fixation of compressor is loose

- Screwed connections have become loose

- Securing elements for screwed connections

missing

- Tighten the screwed connections and secure

them anew

- Vibration metals defective - Replace vibrations metals

Liquid shock

- Liquid refrigerant reaching the compressor

- Adjust / check expansion valve

Check refrigerant lling

Check evaporator fan

- Icing-up of the evaporator

- Oil shocks because of too much oil - Check oil level

Check the dimensioning of pipes (gas velocity)

Replace worn piston rings

Capacity regulator (accessory)

- Switching on and off constantly / oscillating - Check the control

- Defective - Replace capacity regulator valve

Electromagnetic coupling slipping

- see also p. 14 „Malfunction of electromag-

netic coupling“

- Checking

V belt drive,

increased noise generation

- Belts vibrating excessively - Check belt tension

Use tensioning roller / guidance roller

- Incorrect alignment of compressor and motor - Check alignment and adjust anew

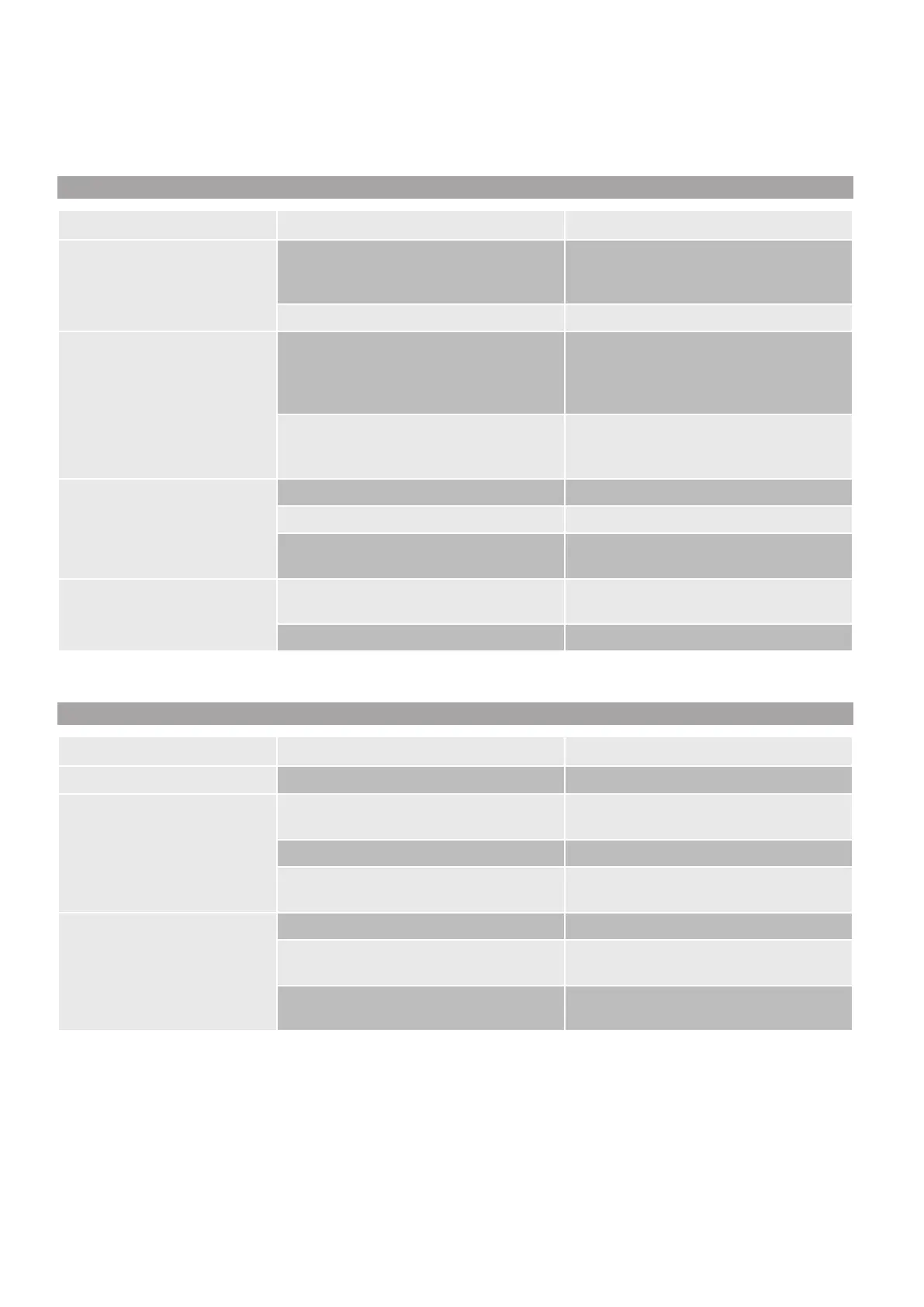

Malfunction of the electromagnetic coupling

Problem Possible cause Remedy

Coupling not switching

- No voltage applied - Apply voltage and check

Coupling slipping too long, get-

ting hot, smoking and squeaking

- Voltage too low - Keep the voltage at 12 or 24 Volts (check

vehicle network)

- Driving power too high - Check operating conditions

- Rotor rubbing at the magnetic eld - Check the seating of the magnet possibly

to high belt tension

Coupling not separating

- Voltage still being applied to the magnet - Check switch / relay

- Coupling is stuck - Disconnect the armature disc from the rotor

mechanically

- Coupling overloaded,

Armature disc is deformed

- Install new rotor ans armature disc

Loading...

Loading...