www.gemu-group.com42 / 46GEMÜ 550

15 Inspection and maintenance

15.3 Removing the actuator

1. Move the actuator A to the open position.

2. Undo union nut a.

3. Remove actuator A from valve body 1.

4. Disconnect actuator A from the control medium lines.

5. Clean all parts of contamination (do not damage parts dur-

ing cleaning).

6. Check parts for potential damage, replace if necessary

(only use genuine parts from GEMÜ).

15.4 Replacing the seals

NOTICE

Gasket!

● Replace gasket 4 each time the actuator is disas-

sembled/assembled.

1. Remove actuator A (see chapter "Removing the actuator").

2. Remove sealing washer 4 from the valve body.

3. Loosen nut e on spindle b (hold spindle b with appropriate

tool that will not damage the spindle surfaces).

4. Remove retaining washer d.

5. Remove seat seal 14.

6. Clean all parts of contamination (do not damage parts dur-

ing cleaning).

7. Insert new seat seal 14.

8. Insert retaining washer d.

9. Apply appropriate thread locking compound on the thread

of spindle b.

10. Fix spindle b in place with nut e (hold spindle b in place

with appropriate tools which do not damage the spindle

surfaces).

11. Insert new sealing washer 4 in valve body 1.

12. Mount actuator A (see chapter "Mounting the actuator").

15.5 Mounting the actuator

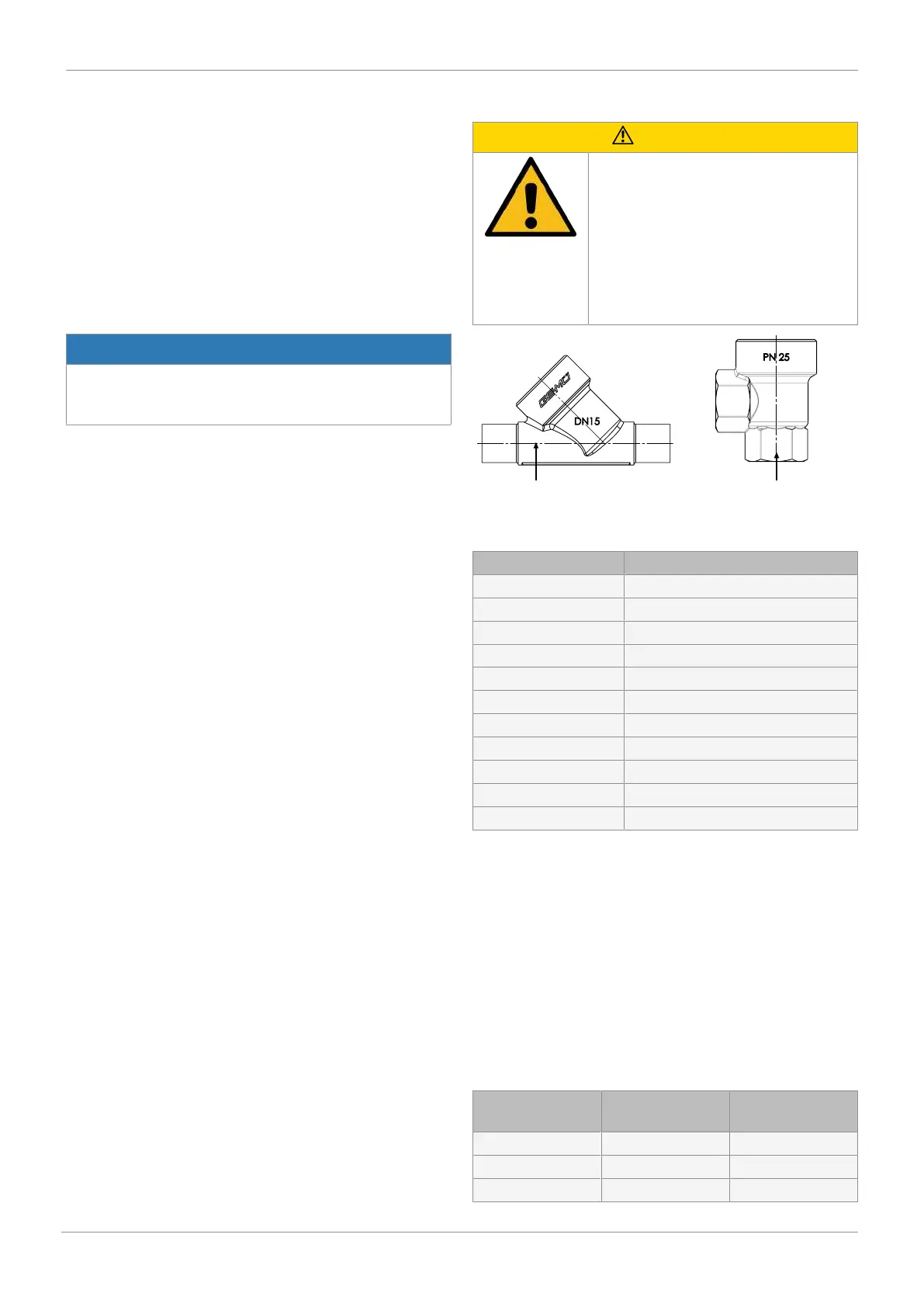

CAUTION

Incorrect combination of actuator and

valve body!

▶ Risk of damage to the actuator and

valve body.

● For control valves with a reduced valve

seat, make sure that the combination

of actuator and valve body is correct.

● Compare the product label of the actu-

ator with the valve body marking.

Valve body marking 2/2-way

body

Valve body marking: Angle

valve body

Fig.12: Valve body marking

Actuator product label Valve body marking

RAxxx R002

RBxxx R004

RCxxx R006

RDxxx R008

RExxx R010

RFxxx R012

RGxxx R015

RHxxx R020

RJxxx R025

RKxxx R032

RMxxx R040

1. Move the actuator A to the open position.

2. Lubricate the thread of union nut a using a suitable lubric-

ant.

3. Place actuator A on valve body 1 approx. 90° anticlock-

wise to the end position of the control medium connectors

and screw it in hand tight using union nut a.

4. Tighten union nut a with an open-end wrench (for torques,

see table). This rotates actuator A clockwise approx. 90°

to the desired position.

5. Move the actuator A to the closed position.

6. With the valve fully assembled, check the function and

tightness.

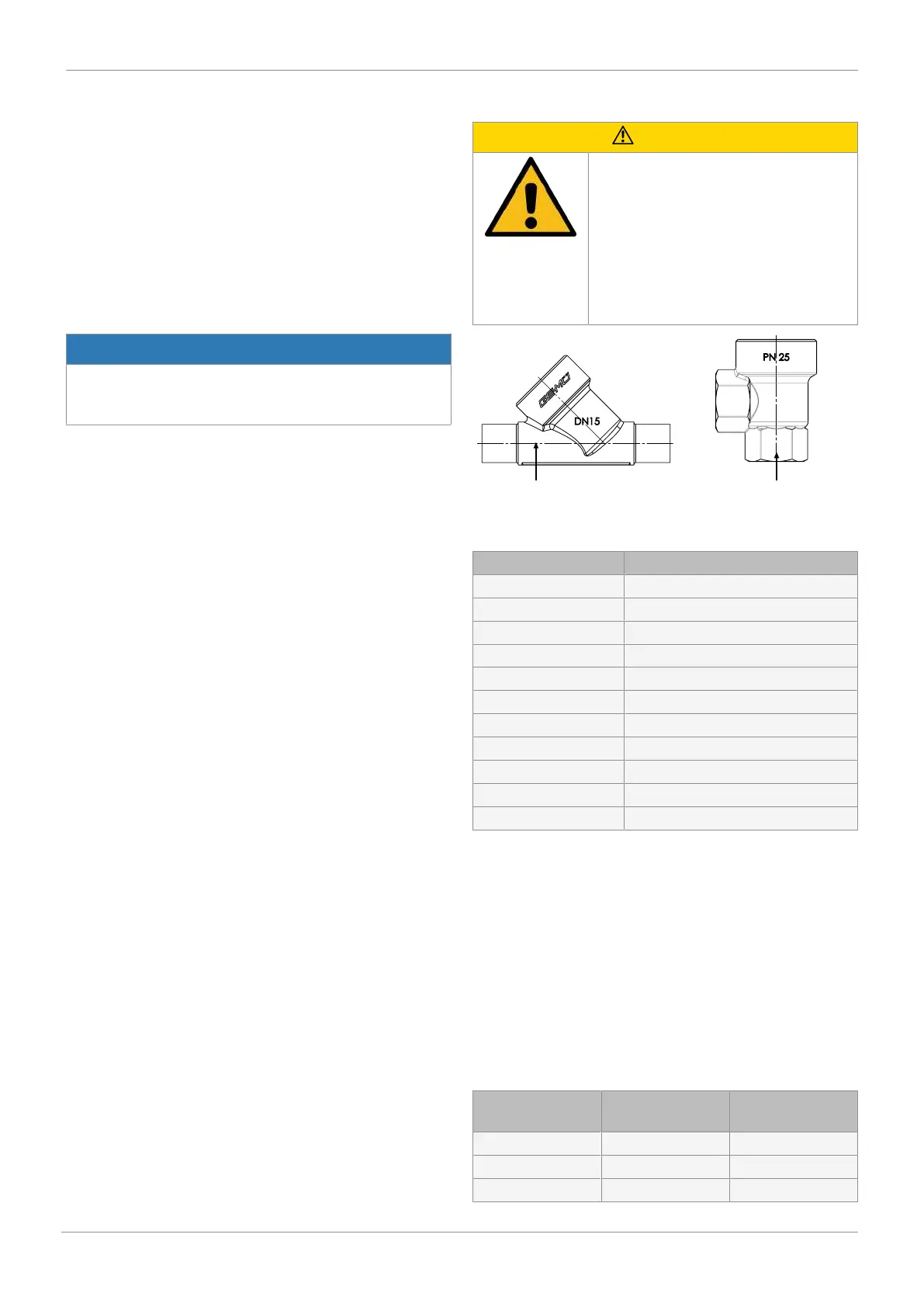

Nominal size

[DN]

Actuator size Torque

[Nm]

DN 6 0G / 0M 35

DN 8 0G / 0M 35

DN 10 0G / 0M 35

Loading...

Loading...