www.gemu-group.com 7 / 46 GEMÜ 550

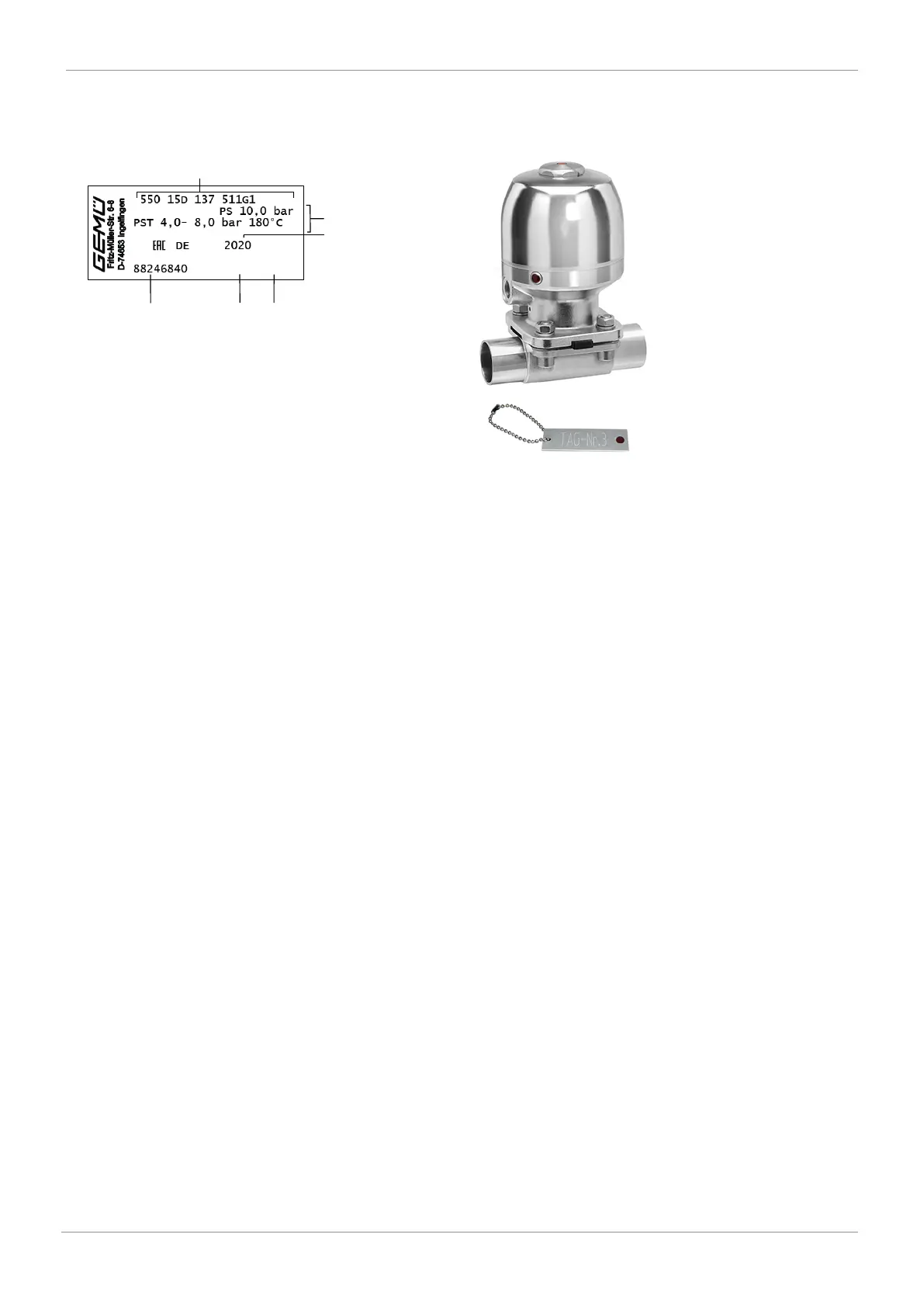

3.7 Product label

The product label is located on the actuator. Product label

data (example):

Design in accordance with order data

Device-specific data

Year of manufacture

Item number Traceability number Consecutive number

- XXXXXXXX|YYYY

The month of manufacture is encoded in the traceability num-

ber and can be obtained from GEMÜ. The product was manu-

factured in Germany.

The operating pressure stated on the product label applies to

a media temperature of 20 °C. The product can be used up to

the maximum stated media temperature. You can find the

pressure/temperature correlation in the technical data.

4 GEMÜ CONEXO

Processing industry 4.0 – Traceability and service

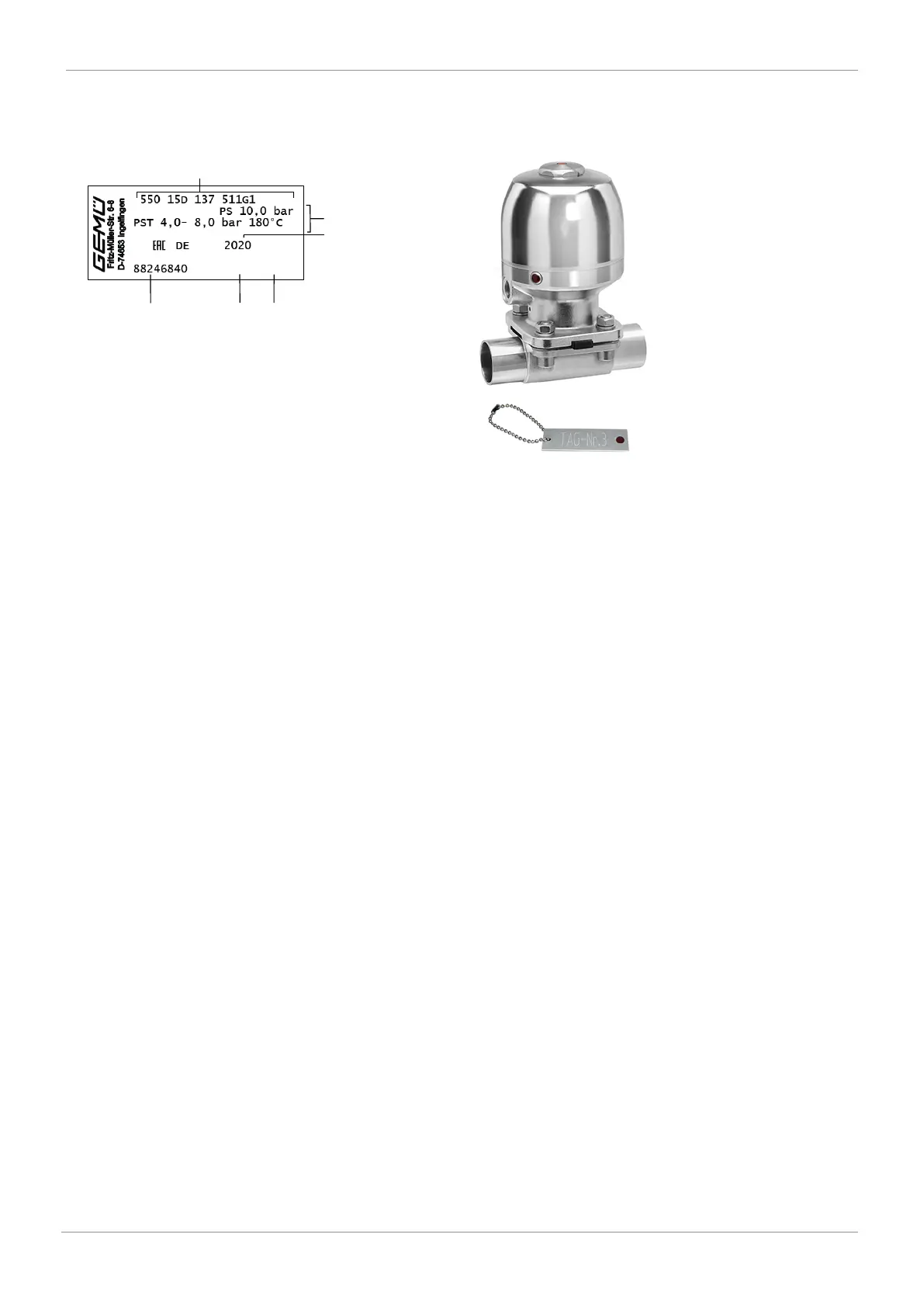

Fig.3: GEMÜ 550 with RFID chips

Description

You can use the GEMÜ CONEXO pen to read and process

identification data from devices and components. In conjunc-

tion with the GEMÜ CONEXO app for maintenance engineers,

field data can be collected, processed, and managed and

archived centrally via the GEMÜ CONEXO portal.

Features

- Captive electronic identification of the valve body, actuator

and diaphragm

- Simplified identification and inventory of devices in the field

- Traceability of the components by providing the serial num-

ber

- Electronic supply of product and project-specific document-

ation

- Optimized maintenance processes thanks to a maintenance

log book and photo documentation

Technical specifications - CONEXO PEN:

- Mobile RFID reading device in the form of a pen

- Bluetooth coupling to mobile end devices

- Stylus for touchscreens (smartphone and tablet)

- UHF signal processing

Technical specifications - CONEXO APP:

- Service software for more efficient maintenance

- Available for tablets and smartphones that have the An-

droid or iOS operating system

- High security standards implemented in portal-reader com-

munication

- Workflow template for customizing the maintenance pro-

cess

- Electronically supported diaphragm evaluation and photo

documentation

4 GEMÜ CONEXO

Loading...

Loading...