651

21/44

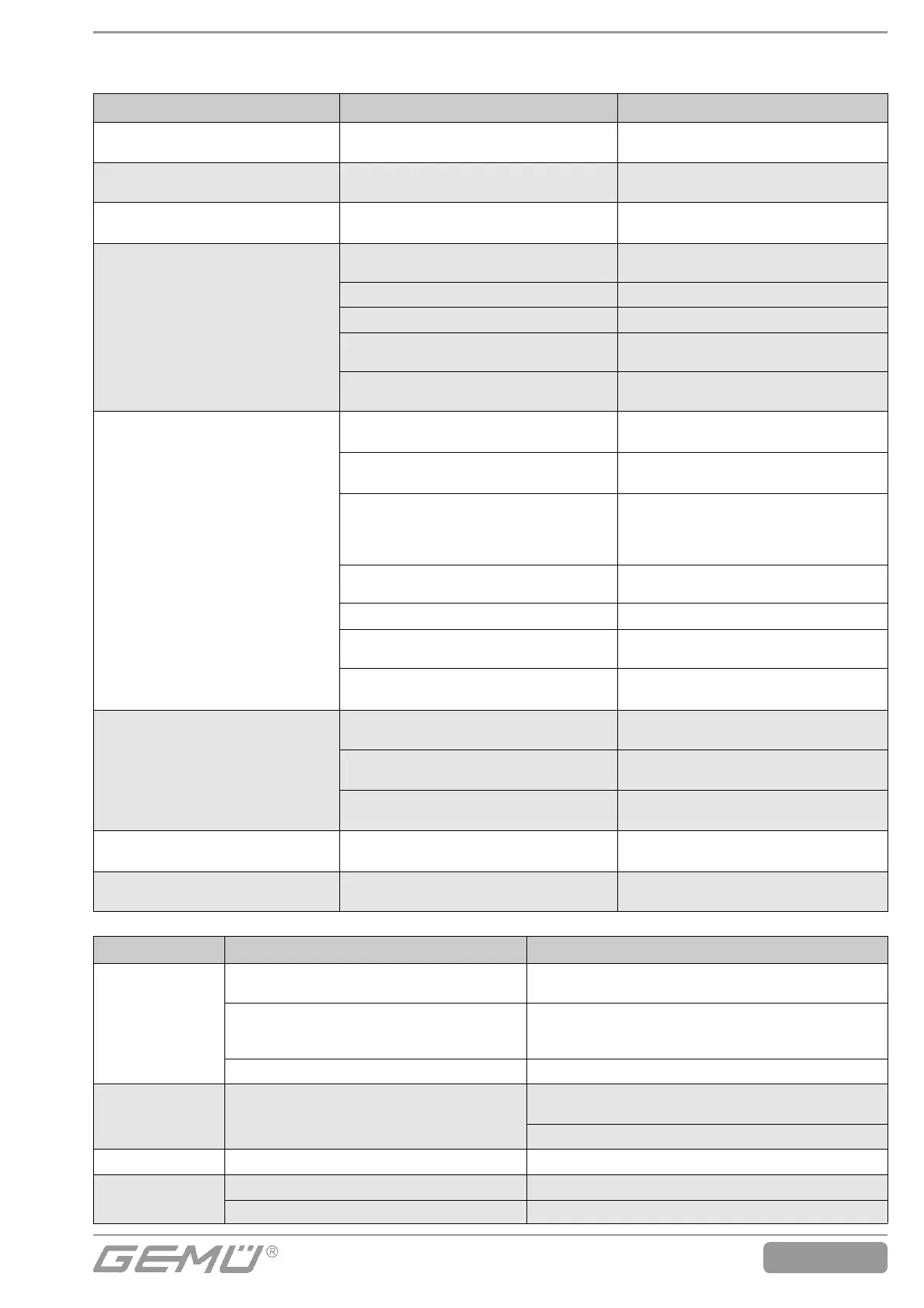

Fault Possible cause Fault clearance

Programming error No air supply during the programming

procedure

Ensure the air supply availability,

re-programme

Programming was deactivated before both

end positions were reached

(Manual programming mode)

Re-programme

Minimum stroke was not reached Adjust minimum stroke, re-programme

Sensor error Sensor limit exceeded Adjust minimum stroke (see Technical data),

re-programme

Note maximum stroke (see Technical data)

Internal error Memory error Re-programme

AS-Interface error Slave is addressed to zero Address the slave

No AS-Interface communication available Check AS-Interface net

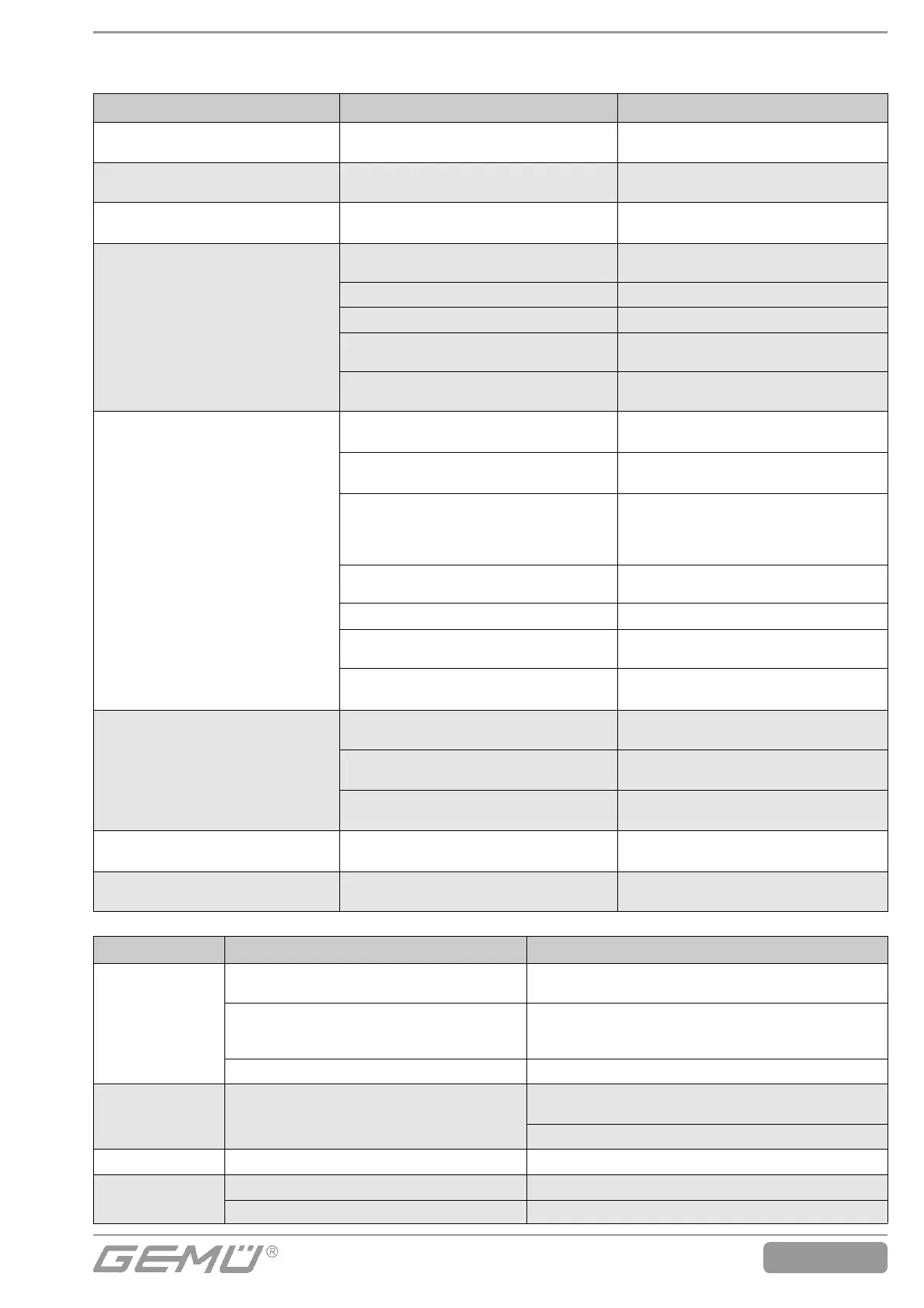

11 Troubleshooting / Fault clearance

Fault Possible cause Fault clearance

Air escapes from ventilation hole

in the upper part

Control piston not sealing Replace actuator

Air escapes from hole on the

distance piece

Spindle sealing leaky Replace actuator and check control

medium for impurities

Medium escapes from the hole

on the distance piece

Valve diaphragm faulty Check valve diaphragm for damage,

if necessary replace diaphragm

Valve doesn't open or doesn't

open fully

Control pressure too low Operate valve with control pressure

specified in data sheet

Pilot valve faulty (for c.f. 1 + 3) Replace actuator

Control medium not connected Connect control medium

Valve diaphragm incorrectly

assembled

Disassemble actuator, check diaphragm

assembly, replace if necessary

Faulty actuator spring (for control

function 2, normally open)

Replace actuator

Valve leaks downstream (doesn't

close or doesn't close fully)

Media operating pressure too high Operate valve with operating

pressure specified in data sheet

Control pressure too low Operate valve with control pressure

specified in data sheet

Foreign matter between valve

diaphragm and valve body weir

Disassemble actuator, remove foreign

matter, check valve diaphragm and

valve body weir for damage and

replace if necessary

Valve body weir damaged Check valve body weir for damage,

if necessary replace valve body

Pilot valve faulty (for c.f. 2 + 3) Replace actuator

Valve diaphragm faulty Check valve diaphragm for damage,

if necessary replace diaphragm

Actuator spring wrong or faulty

(for control function 1, normally closed)

Replace actuator

Valve leaks between actuator and

valve body

Valve diaphragm incorrectly

assembled

Disassemble actuator, check diaphragm

assembly, replace if necessary

Bolting between valve body and

actuator loose

Tighten bolting between valve body

and actuator diagonally

Valve diaphragm faulty Check valve diaphragm for damage,

replace diaphragm if necessary

Valve body connection to piping

leaks

Valve body fitted incorrectly to piping Check installation of valve body in

piping

Valve body leaks Valve body faulty or corroded Check valve body for damage,

replace valve body if necessary

Loading...

Loading...