2-2

SECTION 2: IGNITION

4. Repeat for second armature.

5. Adjust armature air gap.

ADJUST ARMATURE AIR GAP:

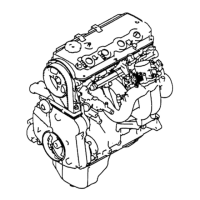

1. Rotate flywheel until magnet is under armature

laminations.

2. Place thickness gauge, 0.20-.30 mm (.008"-.012") between

magnet and armature laminations, Figure 2-3.

3. Loosen mounting screw so magnet will pull armature down

against thickness gauge.

a. Torque screws to 12.2 Nm (9 ft. Ibs.).

4. Rotate flywheel to remove thickness gauge.

5. Repeat for second armature.

Note: Route armature ground wire over breather tube

and away from the flywheel.

Figure 2-3. Adjusting Air Gap

FLYWHEEL

REMOVE FLYWHEEL:

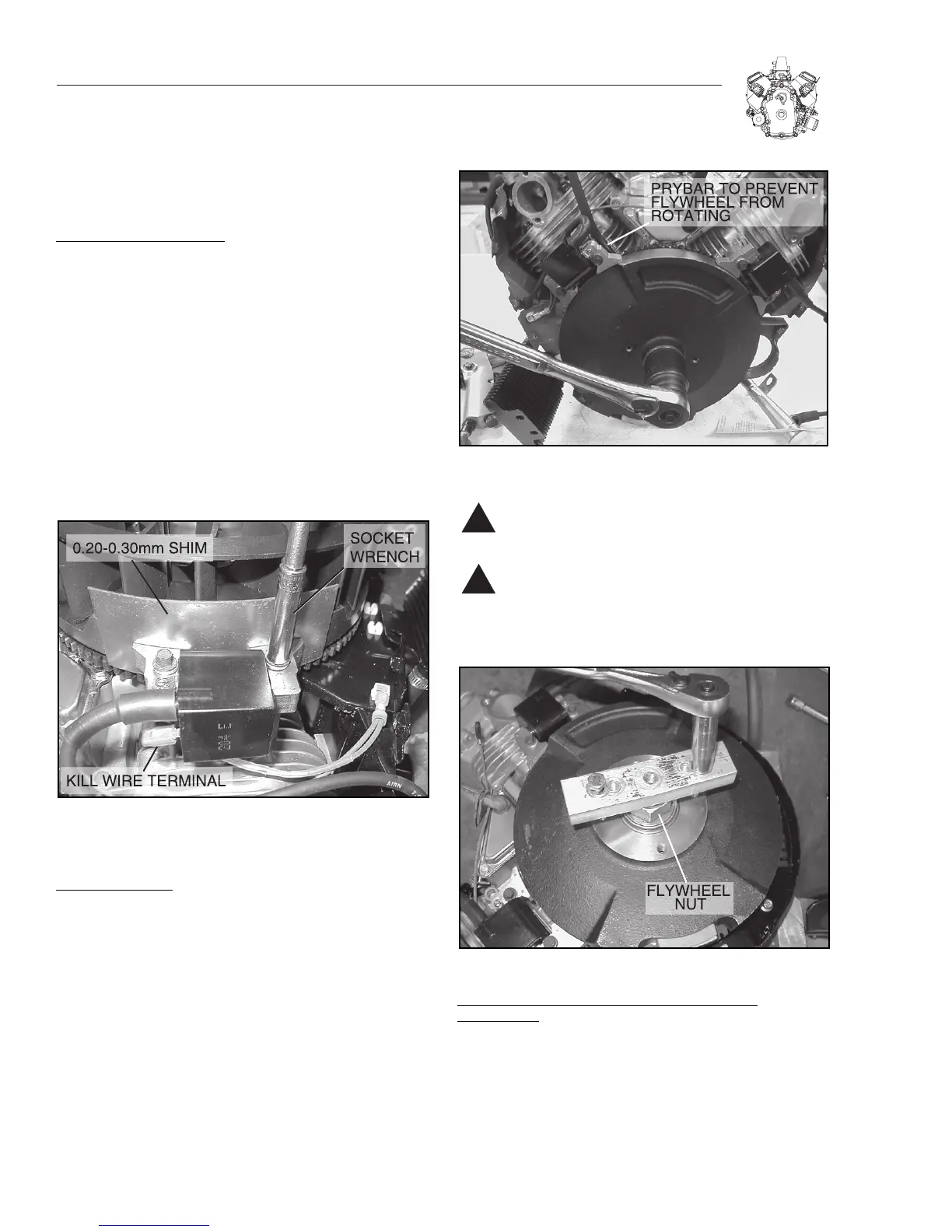

1. Remove flywheel nut and washer, Figure 2-4.

2. Remove fan retainer and fan.

4. Reinstall flywheel nut. Turn nut down flush with top of

threads.

5. Install flywheel puller.

6. Tighten puller screws equally until flywheel loosens,

Figure 2-5.

Figure 2-4. Removing Flywheel Nut

Caution: Flywheel puller bolts may damage lighting

coil if turned in too far.

Caution: DO NOT strike flywheel with a hard object

or a metal tool as this may cause flywheel to shat-

ter in operation. Always use approved flywheel

removal tools.

Figure 2-5. Removing Flywheel

INSPECT FL

YWHEEL KEY, KEYWAYS, FLYWHEEL AND

CRANKSHAFT:

Check flywheel key for damage. Check flywheel for cracks

or keyway damage. Also check crankshaft keyways and taper

for damage, Figure 2-6. Replace crankshaft, if damaged.

Loading...

Loading...