21

GB

2.7 Start-up

Before starting the riveting tool, read and observe the operating instructions as well as safety

information and keep in a safe place.

• Insert fully charged battery in correct position into the blind rivet nut setting tool.

• Select nosepiece and threaded mandrel from Table 2.6 and screw on (M6 in working

position).

Caution!

The air inlets for the motor must not be obstructed; do not insert any objects into them.

2.7.1 Setting the threaded mandrel length x (Fig. 2)

• Set the threaded mandrel length x to the blind rivet nut length by turning the nosepiece B.

• Fully utilise the thread depth of closed blind rivet nuts (Fig. 2; 4).

• Secure setting of nosepiece B with lock nut C.

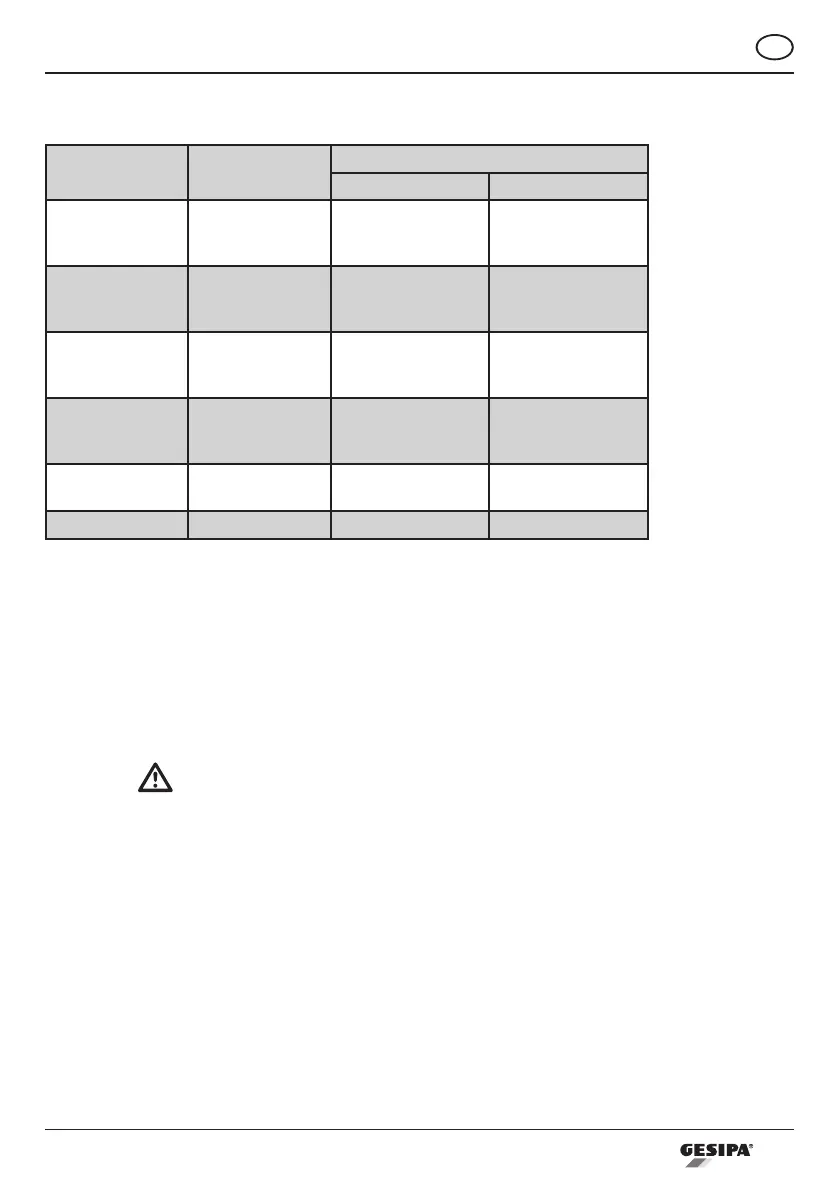

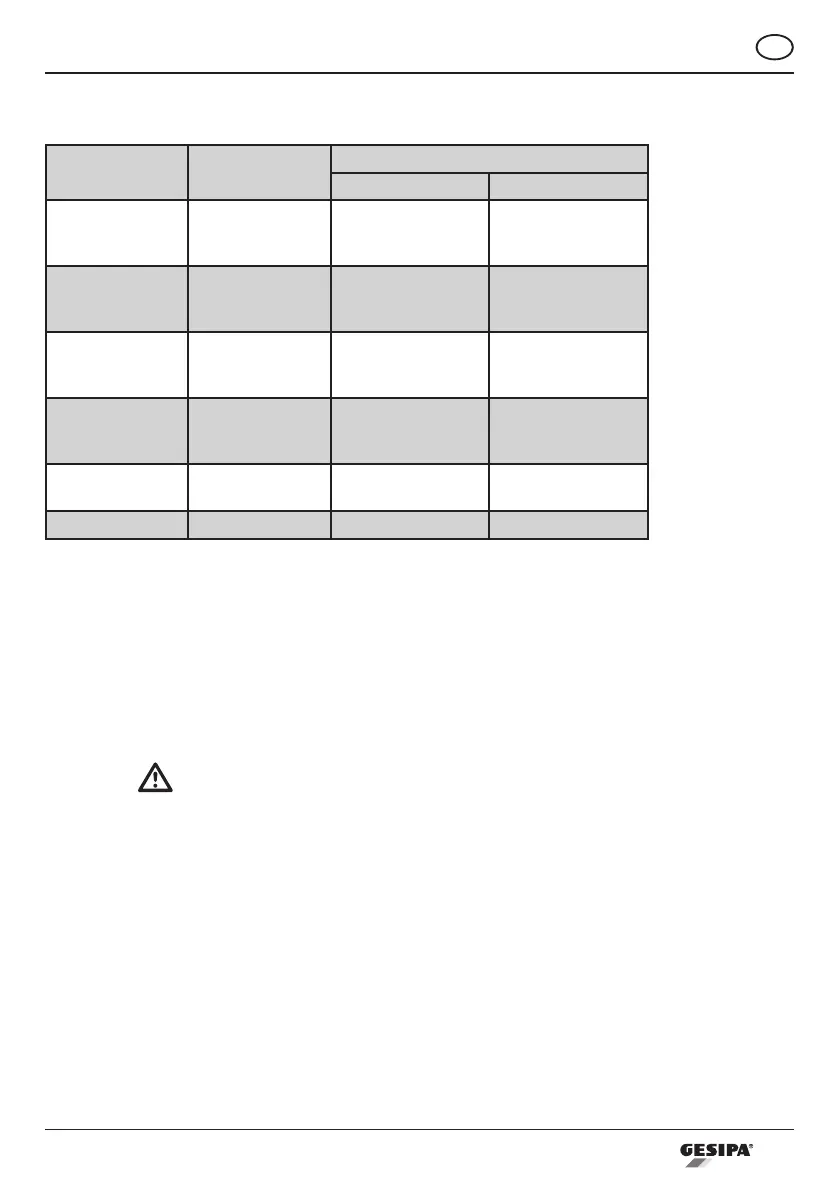

2.6 Threaded mandrels/nosepieces

Thread size Material

Part No.

Threaded mandrel Nosepiece

M3

Aluminium

Steel

Stainless steel

143 5052 143 5065

M4

Aluminium

Steel

Stainless steel

143 5055 143 5066

M5

Aluminium

Steel

Stainless steel

143 5056 143 5067

M6

Aluminium

Steel

Stainless steel

143 5059 143 5068

M8

Aluminium

Steel

143 5063 143 5069

M10 Aluminium 143 5064 143 5070

• The setting stroke y depends on the size of the blind rivet nut (M3-M10) and of the riveta-

ble material z (Fig. 4).

2.7.2 Adjusting the setting stroke y (Fig. 2)

Loading...

Loading...