Servo-i Ventilator System Description of functions

Revision 02 Service Manual 3 - 3

3

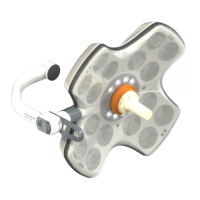

Patient unit

Inspiratory section

Functional Main Blocks diagram marking: 'I'

The main block Inspiratory Section conveys the

breathing gas from its gas inlets for Air and O

2

supply

to the patient breathing system. It comprises the

following main functions:

• Gas Modules – Air and O

2

.

• Connector Muff.

• Inspiratory Pipe.

•O

2

Cell.

• Temperature Sensor.

• Inspiratory Pressure Tube.

• Safety Valve incl. pull magnet.

• Inspiratory Outlet.

• PC 1780 Pneumatic Back-Plane.

Gas modules – Air and O

2

The Air and O

2

Gas Modules regulates the inspiratory

gas flow and gas mixture.

1.Filter

2.Inspiratory valve temperature sensor

3.Supply pressure transducer

4.Flow transducer (Delta pressure transducer and net)

5.Nozzle unit with valve diaphragm

6.Inspiratory solenoid

The Gas Modules are factory calibrated. Each

Gas Module must not be disassembled further

than described in chapter 'Preventive

maintenance'.

Gas inlet

Gas supply is connected to the ventilators gas inlet

nipples. The design of the gas inlet nipples and their

color markings vary according to the standard

chosen.

Gas is to be connected from hospital central gas

supply or from gas cylinders. The Air supply may be

connected from a compressor for medical air.

Filter

The Filter protects the ventilator from particles in the

gas delivered to the Gas Modules. The filter must be

replaced during the ”Preventive maintenance”.

The filter housing and the filter cover are provided

with matching guide pins. These guide pins prevent

mounting of the filter cover (with gas inlet nipple) on

the wrong module.

A non-return valve for the gas inlet is located in the

filter cover. This valve will suppress short pressure

drops in the gas supply.

The non-return valve is also designed to slowly

evacuate compressed gas from the module, if the

gas supply to the module is disconnected.

Inspiratory valve temperature sensor

The temperature of the supplied gas is measured by

the Inspiratory Valve Temperature Sensor. This

sensor is situated in the gas flow.

The output signal from this sensor is used to

compensate for the gas density variations due to

temperature.

Supply pressure transducer

The pressure of the supplied gas is measured by the

Supply Pressure Transducer.

The output signal from this transducer is amplified. It

is then used to calculate the absolute pressure of the

gas to compensate for gas density variations due to

pressure.

Flow transducer

The gas flows through a net (resistance) which

causes a pressure drop. The pressure is measured

on both sides of this net and the differential pressure

value is then amplified.

Loading...

Loading...