Do you have a question about the Getinge HS 6613 AR-2 and is the answer not in the manual?

Explains the use of special symbols for warnings, instructions, and advice within the manual.

Describes symbols used on the unit itself, such as warnings for hot surfaces.

Outlines procedures and required information for reporting accidents or incidents involving the unit.

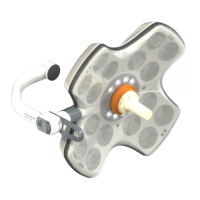

Introduces the HS 66 series of high-pressure autoclaves and their features.

Provides a general overview of the safety features and devices integrated into the autoclaves.

Divides the steam autoclaving process into three main phases: pre-treatment, sterilizing, and post-treatment.

Explains the pre-treatment phase focused on air removal and moisture production for effective sterilization.

Details the sterilizing phase, including temperature monitoring, time, and alarm conditions.

Describes the post-treatment phase for normalizing temperature and moisture content of sterilized goods.

Discusses optimizing processes using control equipment features for different customer requirements.

Describes the automatic process for performing a leak test on the autoclave chamber.

Explains how a printing recorder documents process pressure and temperature on graph paper.

Identifies and describes the instruments and controls located on the loading side of the unit.

Identifies and describes the instruments and controls located on the unloading side of the unit.

Details the procedure for starting a program, including parameter input and prerequisite conditions.

Describes the system's behavior and safety measures when the unit enters an alarm phase.

Lists and explains messages displayed on the operator panel when a process startup is blocked.

Provides instructions on emergency actions to take if a safety valve blows off.

Explains how alarms in standby mode prevent unit startup and the need for technician intervention.

Details how faults during a process stop the program and the options for continuation or technician intervention.

Introduces the list of error messages defined in the control system for fault identification.

Explains when service is required and provides explanations for various service codes displayed on the unit.

Provides general recommendations for safe and effective use of the sterilizer.

Warns about the risk of fire with textile loads due to excessive dryness and heat.

Provides instructions for cleaning the external surfaces of the sterilizer using appropriate cleaners.

Details the procedure for cleaning the inside of the sterilizer chamber, including safety precautions.

Explains the purpose and procedure of the Bowie Dick test for air expulsion and leak detection.

Discusses matching packaging materials to sterilization methods and load carriers for compatibility.

Recommends specific packaging materials like paper and paper/plastic bags for steam sterilization.

Recommends packaging materials for formaldehyde sterilization.

Covers test articles and indicators for routine checks, emphasizing European standards.

Emphasizes using genuine or approved spare parts for optimal operation and safety.

Explains that low-temperature sterilizing with formaldehyde requires special sterilizers and media.

Describes how formaldehyde solution containers are brought to the site and attached.

Discusses CE marking and the importance of using compatible and approved accessories with the autoclave.

Lists compatible accessories, including operator interfaces and documentation systems.

Focuses on the day-to-day operation of the sterilizer, including crucial warnings.

Outlines essential daily preparation steps before operating the sterilizer.

Details the procedure for selecting and initiating a sterilization process.

Explains programs that require a password, often used for special or non-routine operations.

Describes how to start a process using the OP20 operator panel, including password entry.

Provides important safety notes on handling hot goods immediately after unloading.

Lists the final procedures to follow when the day's work is completed.

Explains the meaning of different light indicators for process completion status.

Details emergency procedures for stopping a program or a blowing safety valve.

Outlines the necessary actions to take when an alarm condition is detected.

Defines key technical terms used within the manual for clarity.

Illustrates and describes the indicators and controls of the OP 10 operating panel.

Provides a detailed description of the various indicators and control elements on the unit's panel.

Explains the two-line display window and how information and fault messages are presented.

Describes how to navigate through menus and lists using the panel's arrow keys and ENTER button.

Explains the function of program selection buttons and accessing the program list.

Details the function of the navigation keys (arrow keys and ENTER) for cursor control and selection.

Explains how to edit fields for parameter entry and saving values.

Describes the process of entering passwords for access and handling incorrect entries.

Presents a visual hierarchical overview of the operator's menu structure and navigation paths.

Provides a detailed explanation of each main menu level and its available options.

Explains the display and options for Main Menu 1, including selecting cycles and changing parameters.

Details how to select a program cycle using arrow keys and ENTER, noting password requirements.

Explains how to access and modify parameters, distinguishing between adjustable and information parameters.

Presents a summary of available program combinations with their parameters and settings.

| Category | Medical Equipment |

|---|---|

| Type | Steam Sterilizer |

| Model | HS 6613 AR-2 |

| Manufacturer | Getinge |

| Power Supply | 50/60 Hz |