11

THE PROCESS

The steam sterilizing process

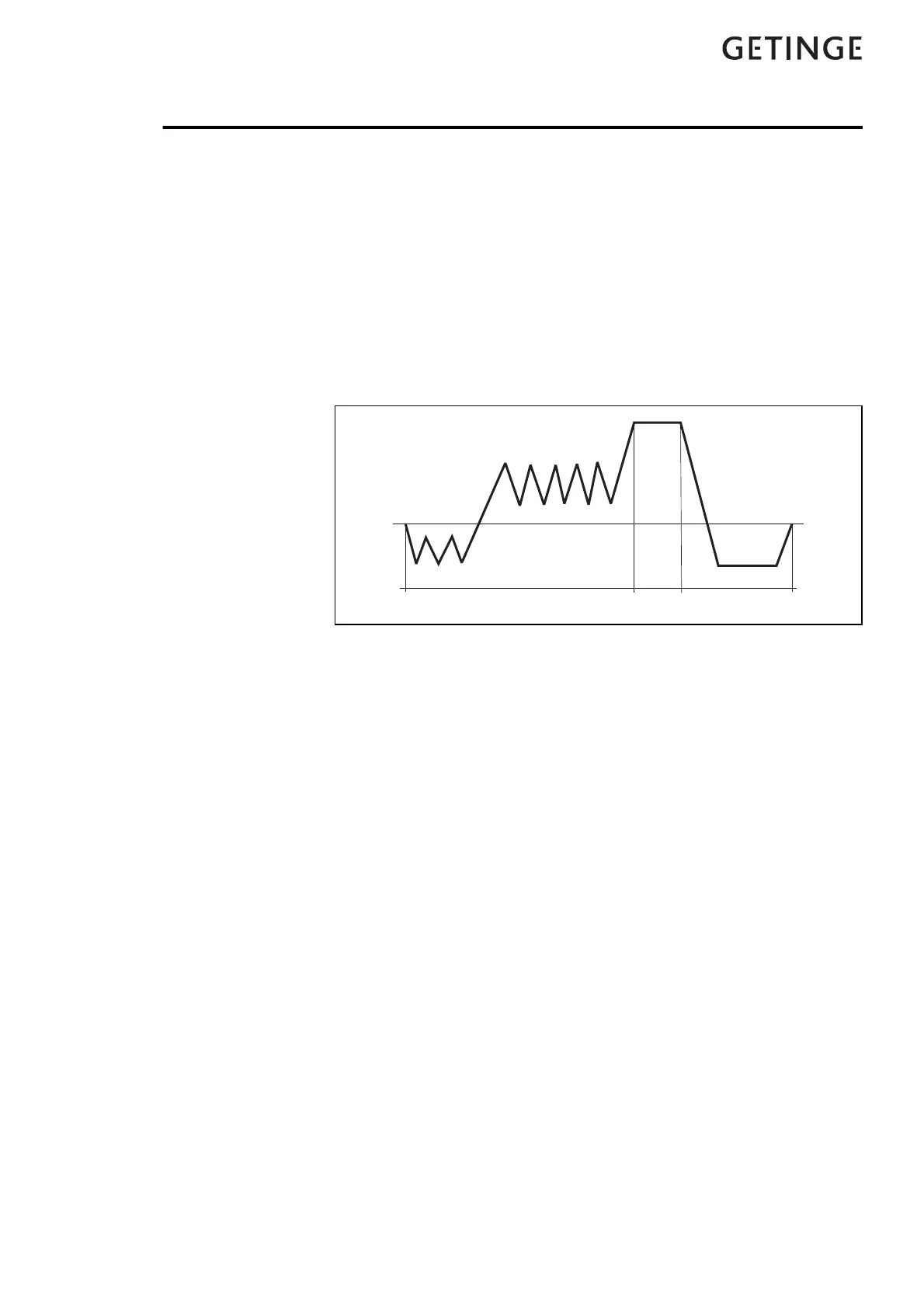

The universal steam autoclaving process can be divided into three main

phases:

A Pre-treatment

B Sterilizing

C Post-treatment

Pre-treatment

It has been found that moisture is an essential element in achieving

sterility with steam. It is therefore important that the steam comes into

close contact with the micro-organisms to be killed.

A pre-treatment phase consisting of a number of pressure variations

following a certain pattern effectively removes air from various types of

goods and produces the moisture required in the subsequent sterilizing

phase. Depending on the equipment of the sterilizer, steam may pass

through before the evacuations.

Air removal when autoclaving liquids in open containers is by

applying a vacuum or by flowing steam, to ensure that the liquid does

not boil during the decompression periods in a pulsating procedure.

Sterilizing

For sterilizers equipped with a computerized control unit, the sterilizing

time starts at the instant in the pre-treatment phase of the process when

the chamber temperature sensor signals a temperature equal to or higher

than the sterilizing temperature specified for the current program. An

alarm sounds if the temperature sensor registers a value outside the

temperature band, or if the temperature differs by more than the

permitted amount from the chosen sterilizing temperature.

Loading...

Loading...