13

Maintenance program

Leak test

Fully automatic process for steam autoclaves

With autoclaves equipped with an analogue pressure transducer the leak

test can easily be automatically performed. The leak test is to be

performed with an empty chamber. The chamber additionally has to

have been warm, for example as a result of a heating program having

been run beforehand.

The checking process has its own program button (see program list)

which starts with the vacuum system evacuating the chamber.

Depending on the equipment of the sterilizer, steam may pass through

before the evacuation. The pump in the vacuum system stops when a

deep vacuum has been created. For a short period of time after this

evacuation a slight rise in the chamber pressure takes place which is not

due to leakage but results from evaporation of condensate and

temperature-volume changes in the recently rarefied residual steam.

It is therefore not possible to establish that an increase in pressure in

the chamber is caused by leakage until conditions in the chamber have

stabilized. It is not until about 10 minutes after the pump has stopped

that the pressure and time start to be measured.

A satisfactory leak test allows for a maximum permissible pressure rise

of 13 mbar / 10 minutes.

With double-ended autoclaves, the loading door opens after a

completed leak test either automatically or manually, depending on how

it has been programmed.

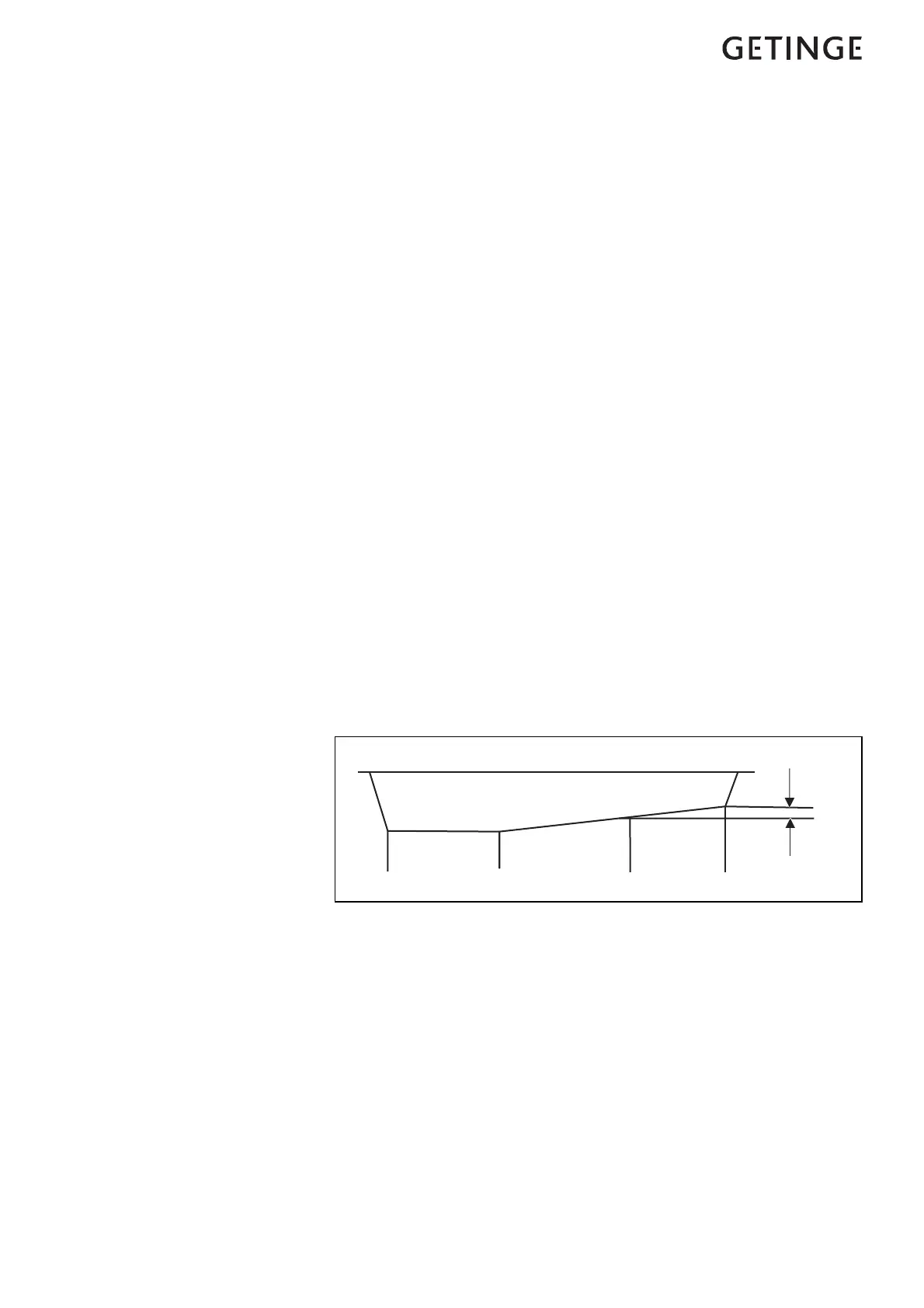

A Normal vacuum 5 min.

B Stabilization of chamber atmosphere 10 min.

C Check time 10 min.

D Pressure stepping max. 13 mbar.

Loading...

Loading...