Description of functions Servo-i Ventilator System

3 - 4 Service Manual Revision 02

3

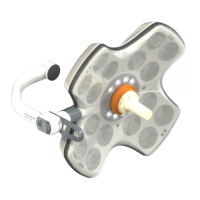

Nozzle unit

The plastic Nozzle Unit contains a valve diaphragm.

The valve diaphragm, controlled by the Inspiratory

Solenoid, regulates the gas flow through the Gas

Module.

The complete plastic nozzle unit must be replaced

during the 'Preventive maintenance'.

After replacement, allow the diaphragm to settle

during approx. 10 minutes before gas pressure is

connected to the Gas Module.

Inspiratory solenoid

The gas flow through the Gas Module is regulated by

the Inspiratory Solenoid via the Nozzle Unit.

The current supplied to the solenoid is regulated so

that the gas module will deliver a gas flow according

to the settings on the User Interface.

Gas module key

The Gas Modules are provided with a mechanical

key to prevent that the module is mounted in the

wrong slot.

The key consists of a plastic guide mounted

underneath the module and a corresponding guide

mounted in the patient unit.

ID PROM

Each Gas Module is provided with an ID-PROM. The

ID information can be read by the Servo-i System.

Connector muff

The Connector Muff connects the Gas Module

outlets to the Inspiratory Pipe inlet.

Inspiratory pipe

The Inspiratory Pipe leads the gas from the

Connector Muff to the Inspiratory Outlet.

The Inspiratory Pipe comprises:

• Housing and locking lever for the O

2

Cell with its

bacteria filter.

• Housing for the Safety Valve.

• Connection for measurement of inspiratory

pressure.

The pipe is provided with internal flanges with the

purpose to improve mixing of O

2

and Air.

O

2

cell

The O

2

Cell is mounted in a housing on the

Inspiratory Pipe and is protected by a bacteria filter.

SVX9015

Maintenance including exchange of bacteria filter

according to the User´s manual. The bacteria filter

must also be replaced during the 'Preventive

maintenance'.

The O

2

cell gives an output voltage proportional to

the partial pressure of oxygen inside the Inspiratory

pipe. At constant ambient pressure this output is

proportional to the O

2

concentration in percent.

In each O

2

cell, the output signal will stay at a fairly

constant level usually within 10–17 mV in normal air

and at standard barometric pressure during the life

time of the cell.

The life time of the cell is affected by the O

2

concentration. With a concentration (at the cell) in %

and expected cell life time in hours the following

applies at 25

o

C (77

o

F):

O

2

Conc. x Expected cell life = 500 000% hours.

The O

2

cell is automatically calibrated each time a

Pre-use check is performed (if O

2

is connected to the

ventilator).

If the ventilator has continually been in use for a long

time, the measured O

2

concentration may drop due

to normal degradation of the O

2

cell. This will activate

a nuisance alarm. For further information, refer to the

User's manual, chapter section 'O

2

cell adjustment'.

Note: Pre-use check is recommended to use to

calibrate the O

2

cell.

An ID PROM is integrated into each O

2

cell. Its ID

information and remaining lifetime can be read by the

Servo-i.

Loading...

Loading...