6.0 SYSTEM DETAILS

6.4 SYSTEM FILLING AND PRESSURISING

1. A filling point connection on the central heating return

pipework must be provided for initial filling and pressurising

and subsequent topping up of the system.

A filling loop is provided loose with the boiler

2. The filling method adopted must comply with all relevant

water supply regulations and use approved equipment.

3. Further details are given in;

for GB: Guidance G24.2 and recommendation R24.2 of the

Water Regulations Guide.

for IE: the current edition of I.S. 813 “Domestic Gas

Installations”.

4. The sealed primary circuits may be filled or topped up using

a temporary connection between the circuit and a supply pipe,

provided a ‘Listed’ double check valve or some other no less

effective backflow prevention device is permanently connected

at the inlet to the circuit and the temporary connection is

removed after use.

1. The appliance expansion vessel is pre-charged to 1 bar.

Therefore the minimum cold fill pressure is 2 bar. The vessel is

suitable for correct operation for system capacities up to 84

litres. For greater system capacities an additional expansion

vessel must be fitted.

For GB refer to BS 7074 Pt 1.

For IE, the current edition of I.S. 813 “Domestic Gas

Installations”.

6.6 PRESSURE RELIEF VALVE

1. The pressure relief valve is set at 3 bar, therefore all

pipework, fittings, etc. should be suitable for pressures in

excess of 3 bar and temperature greater than 100°C.

2. The pressure relief discharge pipe should be not less than

15mm diameter, run continuously downward, and discharge

outside the building, preferably over a drain. It should be

routed in such a manner that no hazard occurs to occupants or

causes damage to wiring or electrical components. The end of

the pipe should terminate facing down and towards the wall.

NOTE: Boiling water/steam could discharge from the pipe,

therefore it s

hould be terminated away from windows and

doors.

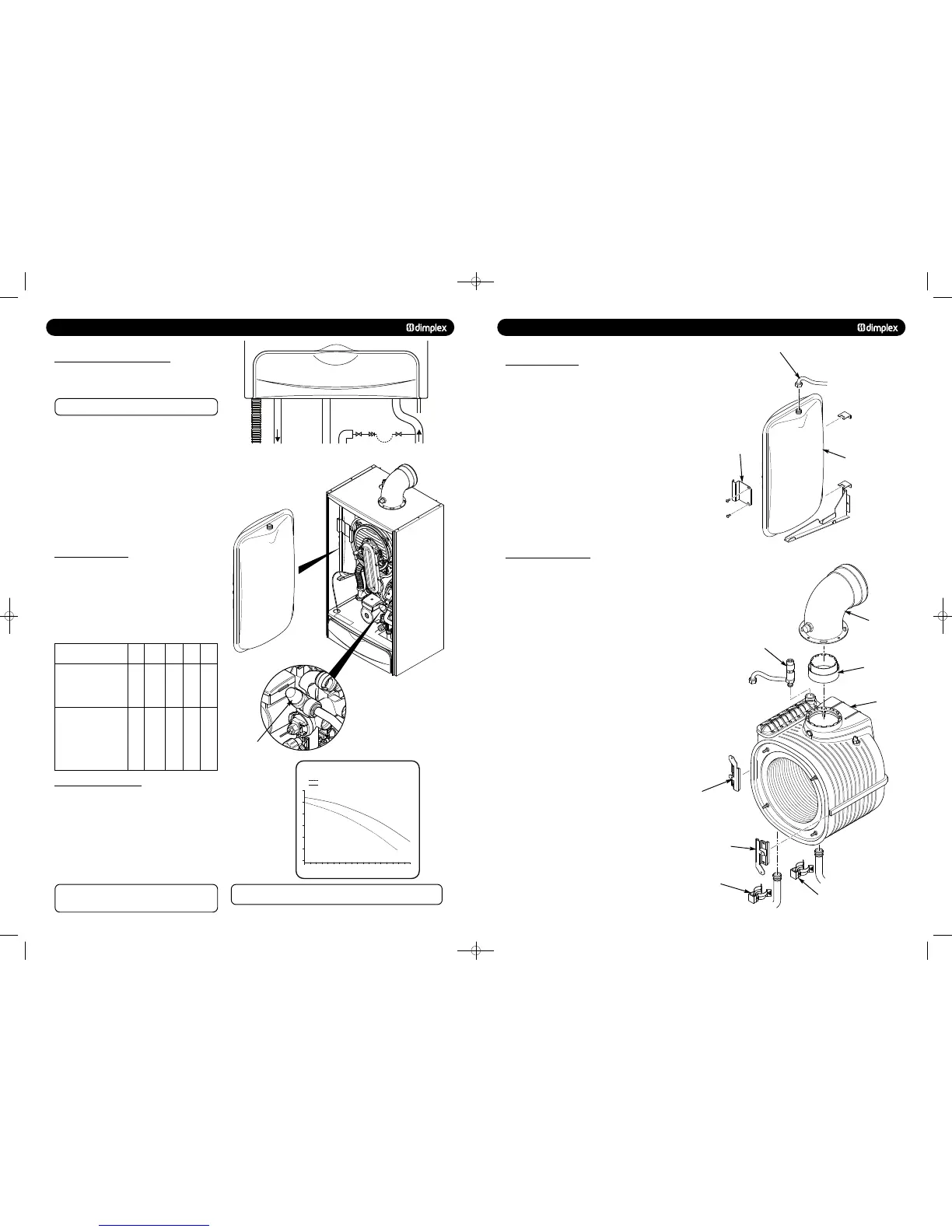

Mains

Supply

CH

Return

Pressure

Relief

Discharge

Pipe

Temporary

Loop

Stop

Val ve

Stop

Val ve

Double

Check

Val ve

GasCH

Flow

Condensate

1

0123456789101112131415161718

2

3

4

5

6

7

FLOW RATE Ltr/min

PUMP HEAD (mH

2

O)

System 18

System 30

AVAILABLE PUMP HEADS

Expansion Vessel

Pressure

Relief Valve

Vessel charge and initial

system pressure

Total water content of

system using 8 litres

capacity expansion

vessel supplied with

appliance

For systems having a

larger capacity multiply

the total system capacity

in litres by this factor to

obtain the total minimum

expansion vessel capacity

required in litres

bar

litres

0.5

96

0.75

84

0.093

1.0

73

1.5

50

Fig. 6

Fig. 9

Fig. 10

NOTE: Do not use the pressure relief valve to drain the system, because dirt

and debris could preven

t the valve seating correctly.

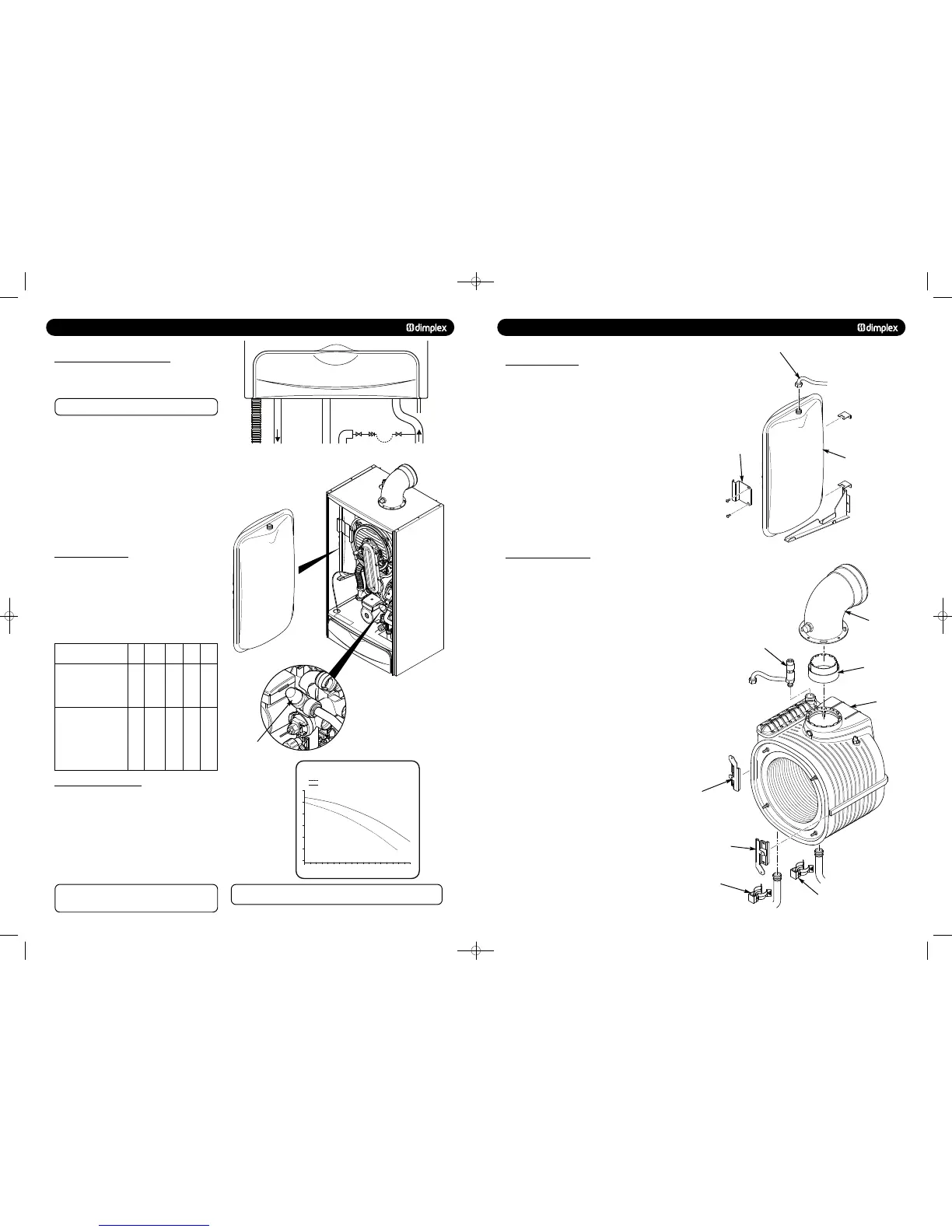

1. Drain the primary circuit and undo the nut on the vessel

connection pipe.

2. Remove the two screws holding the retaining bracket and

remove the bracket (Fig. 67).

3. Carefully slide out the vessel from the boiler.

4. Reassemble in reverse order.

Expansion Vessel

Vessel Connection Pipe

Retaining

Bracket

Flue Elbow

Flue Adaptor

Main Heat

Exchanger

Left Hand

Retaining Bracket

Right Hand

Retaining Bracket

Flow Pipe

Retaining Clip

Return Pipe Retaining Clip

Manual Air Vent

13.17 MAIN HEAT EXCHANGER

1. Drain the primary circuit.

2. Remove the electrode leads, noting their positions as

described in section 13.2.

3. Remove the valve and fan assembly as described in Section

13.3.

4. Examine the gasket and replace if necessary.

5. Undo the four nuts securing the burner door and remove the

cover plate from the heat exchanger.

6. Remove the two clips from the flow and return pipes on the

bottom of the heat exchanger and slide out the pipes (Fig. 68).

7. Remove the clip holding the manual air vent and remove the

pipe from the top of the heat exchanger.

8. Remove the four screws holding the left and right hand

retaining brackets and remove the brackets.

9. Remove the four screws securing the flue to the top of the

boiler. Lift the flue adaptor out of the flue outlet in the top of

the heat exchanger.

10. Carefully slide the heat exchanger out of the boiler.

11. Reassemble in reverse order.

751262 MANUAL 19/10/10 08:41 Page 12

Loading...

Loading...