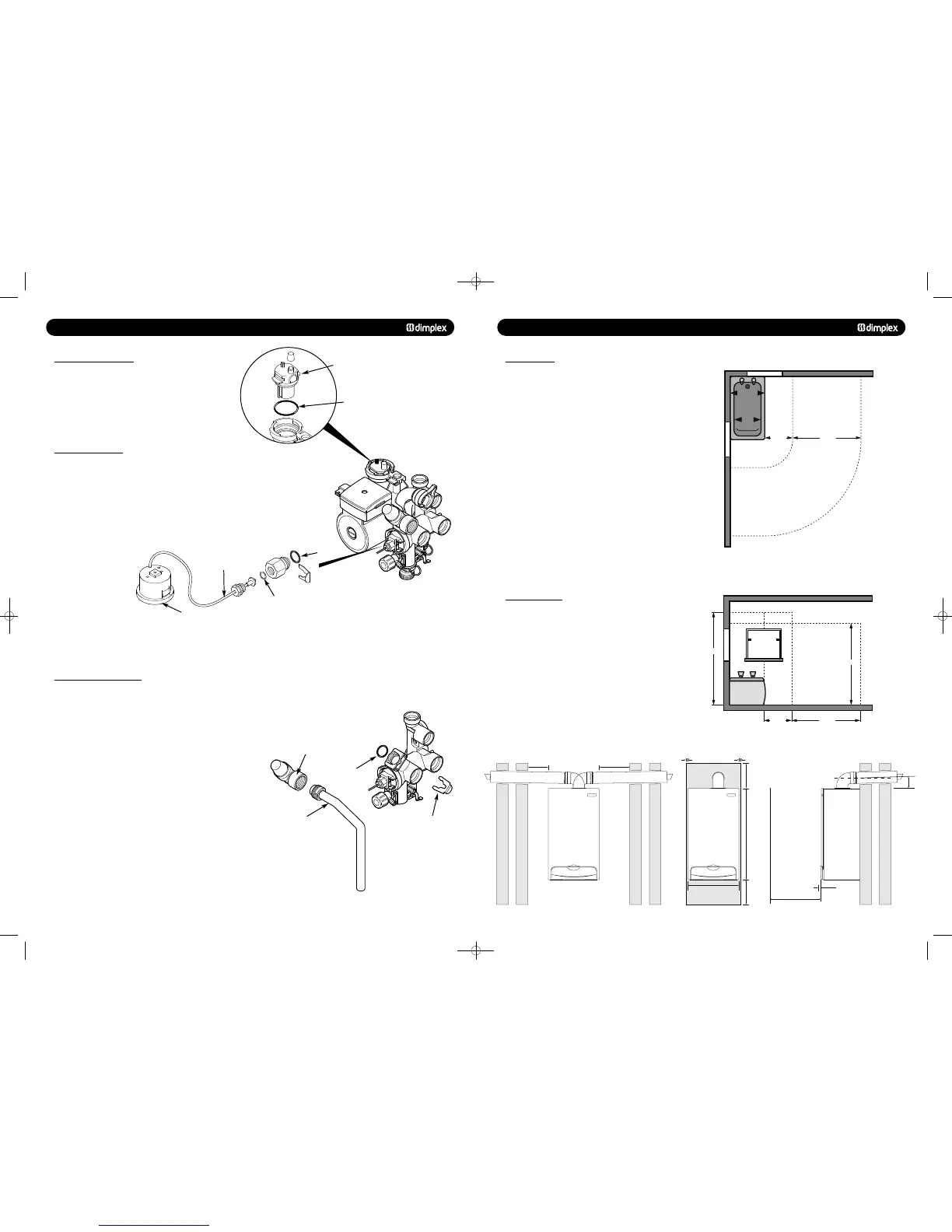

13.0 CHANGING COMPONENTS

13.12 AUTOMATIC AIR VENT

1. Drain the primary circuit and rotate the automatic air vent

1

/

4

turn and remove from the pump body.

2. Examine the ‘O’ ring seal, replacing if necessary, and fit it to

the new automatic air vent.

3. Reassemble in reverse order.

1. Drain the primary circuit and undo the nut on the pressure

gauge capillary.

2. Examine the ‘O’ ring seal, replace if necessary.

3. Unclip the facia from the control box

4. Lever the barbs securing the gauge to remove the gauge

from the control box (Fig. 64).

5. Reassemble in reverse order.

13.14 PRESSURE RELIEF VALVE

1. Drain the primary circuit.

2. Disconnect the discharge pipe from the valve. Ease off the

retaining clip (Fig. 66).

3. Note the orientation of the valve, rotate it and withdraw it

from the manifold.

4. Fit the new valve and ‘O’ ring and set to the previously

noted orientation. Reassemble in reverse order.

Automatic Air Vent

‘O’ Ring

Pressure Gauge

Pressure

Relief Valve

Retaining Clip

‘O’ Ring

Discharge Pipe

Capillary

‘O’ Ring

‘O’ Ring

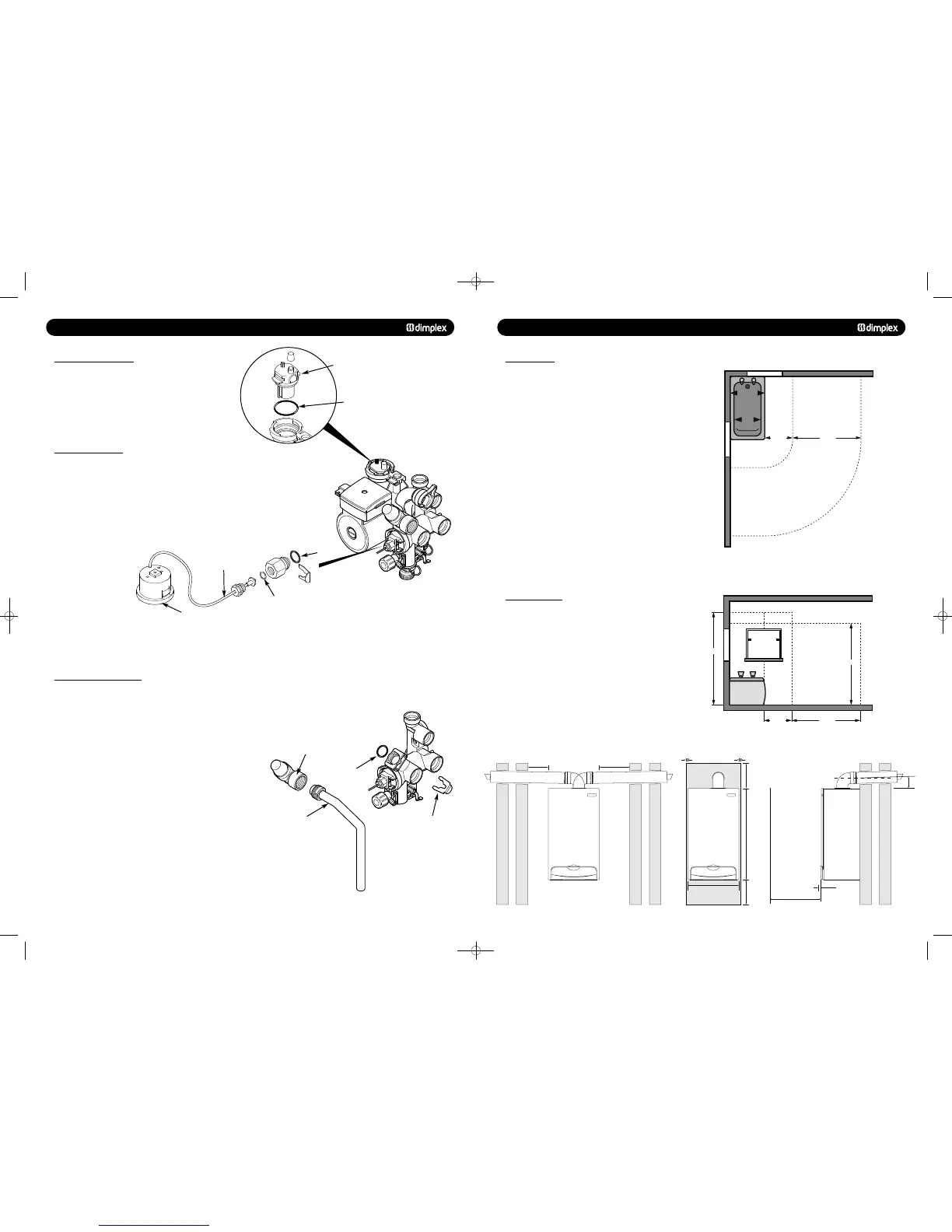

7.0 SITE REQUIREMENTS

7.1 LOCATION

1. The boiler may be fitted to any suitable wall with the flue

passing through an outside wall or roof and discharging to

atmosphere in a position permitting satisfactory removal of

combustion products and providing an adequate air supply. The

boiler should be fitted within the building unless otherwise

protected by a suitable enclosure i.e. garage or outhouse. (The

boiler may be fitted inside an unvented cupboard - see section

7.3).

2. If the boiler is fitted in a room containing a bath or shower

reference must be made to the relevant requirements.

In GB this is the current I.E.E. Wiring Regulations and Building

Regulations.

In IE reference should be made to the current edition of I.S.

813 “Domestic Gas Installations” and current ETCI rules.

(Fig. 11 shows zone dimensions for a bathtub. For other

examples refer to Section 601 of the current I.E.E. Wiring

Regulations) reference must be made to the relevant

requirements.

The boiler is IPX4 rated and can be fitted in Zone 2 (Fig. 11).

3. If the boiler is to be fitted into a building of timber frame

construction then reference must be made to the current

edition of Institute of Gas Engineers Publication IGE/UP/7 (Gas

Installations in Timber Framed Housing).

© Dimplex Boilers 2008

1. A flat vertical area is required for the installation of the

boiler.

2. These dimensions include the necessary clearance around

the boiler for case removal, spanner access and air movement.

Additional clearances may be required for the passage of pipes

around local obstructions such as joists running parallel to the

front face of the boiler.

Zone 2

Zone 2

Zone 1

Zone 0

Zone 3

Zone 3

Window Recess

Zone 2

Window

Recess

Zone 2

0.6 m 2.4 m

Zone 2 Zone 3

Zone 2Zone 1

Zone 0

Zone 3

Outside Zones

Ceiling

Window

Recess

Zone 2

3.0 m

2.25 m

0.6 m 2.4 m

285mm Wall

450mm Min

For Servicing

Purposes

5mm Min

In Operation

2.5°

5mm Min

446mm

5mm Min

796mm

200mm

200mm

5mm Min

5mm Min

285mm Wall

285mm Wall

751262 MANUAL 19/10/10 08:41 Page 13

Loading...

Loading...