10.0 COMMISSIONING

10.2 FACTORY SETTINGS

1. With the boiler firing at maximum gas rate, check that the

inlet pressure at the appliance is 19mbar +/- 1mbar when

measured at the inlet pressure test point (Fig. 44).

To set the boiler to maximum gas rate see section

11.0 (Service Mode).

2. Check the maximum and minimum gas rate at the gas meter

according to the table below using a stopwatch.

This boiler is supplied factory set for operation on

natural gas. No further adjustments of the air/gas ratio

valve or measurement of the combustion performance are

necessary at the time of installation and commissioning.

This is provided the appliance has been installed according

to these instructions and the inlet gas pressure is within

our specification.

If any doubts exist over the above checks then the

combustion of the appliance can be measured as described

in Section 12.0 of these instructions providing;

• The person carrying out the measurement has been

assessed as competent in the use of a flue gas analyser

and the interpretation of the results.

• The flue gas analyser used, meets the requirements of

BS7927 or BS-EN50379-3.

• The flue gas analyser is calibrated in accordance with the

manufacturers requirements.

10.3 INLET PRESSURE AND GAS RATE CHECKS

1. On completion of the gas inlet pressure and gas rate checks,

it is necessary to check the following:

• The appliance installation conforms to these instructions.

• The installation and integrity of the full flue system

including the seals in the flue pipes.

• The boiler combustion circuit, including the burner door

seal, combustion door seal.

2. The recorded combustion values should be compared with

the values in Table 1 and Table 2 (see Section 12.2).

3. If the combustion value(s) is outside the values specified in

Section 12.2 (Tables 1 & 2), do not attempt to adjust the

air/gas ratio valve, please ring the helpline number -

0844 371 1121. If in doubt - ASK.

10.4 COMBUSTION CHECKS DURING COMMISSIONING

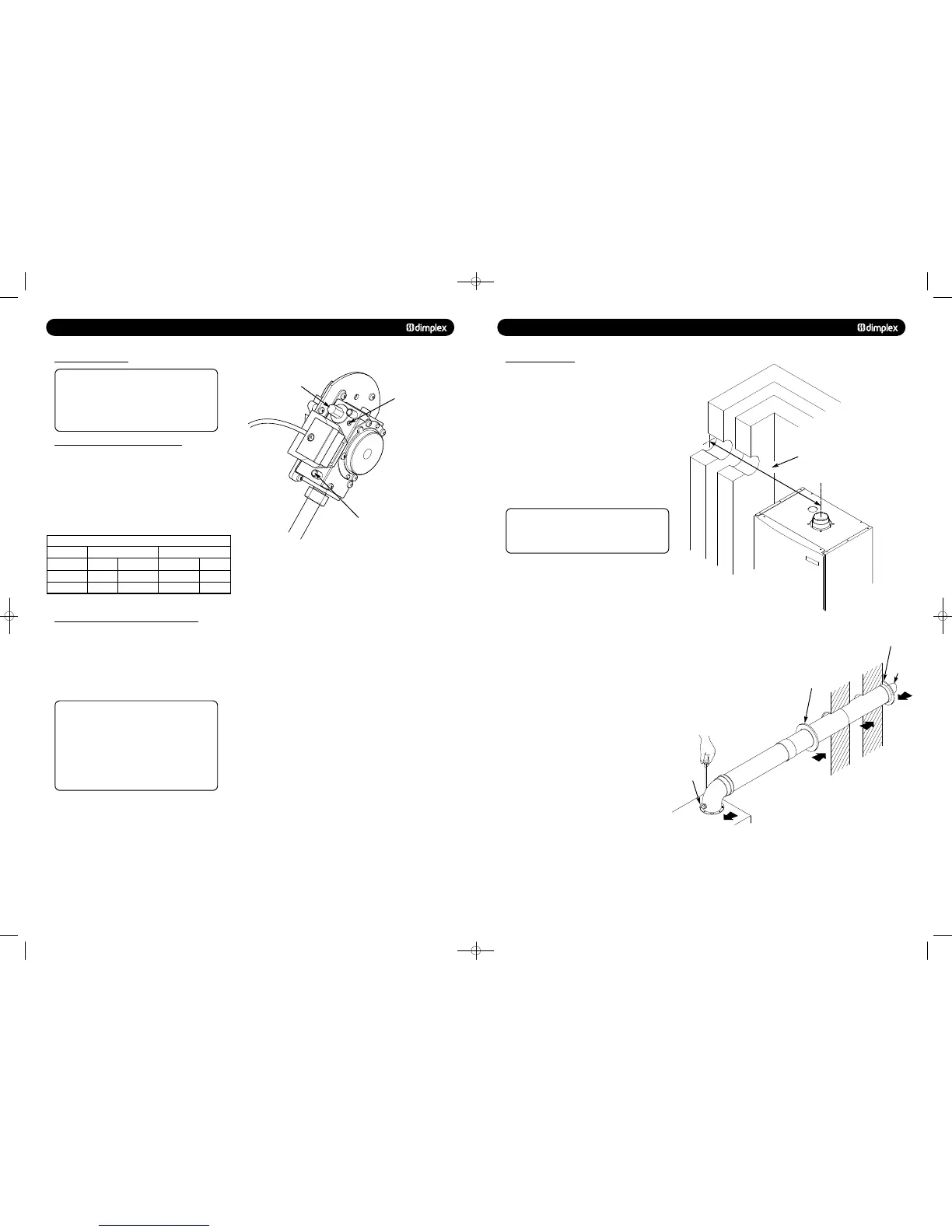

Gas Rates (Natural Gas) after 5 minutes from cold

Maximum RateBoiler Model

Factory set - warranty

void if adjusted

Throttle Adjuster Screw

9.0 INSTALLATION

9.5 FITTING THE FLUE

HORIZONTAL TELESCOPIC FLUE

1. For correct flue installation please refer to the installation

instructions that are provided with the individual flue kit as

described in sections 7 & 8.

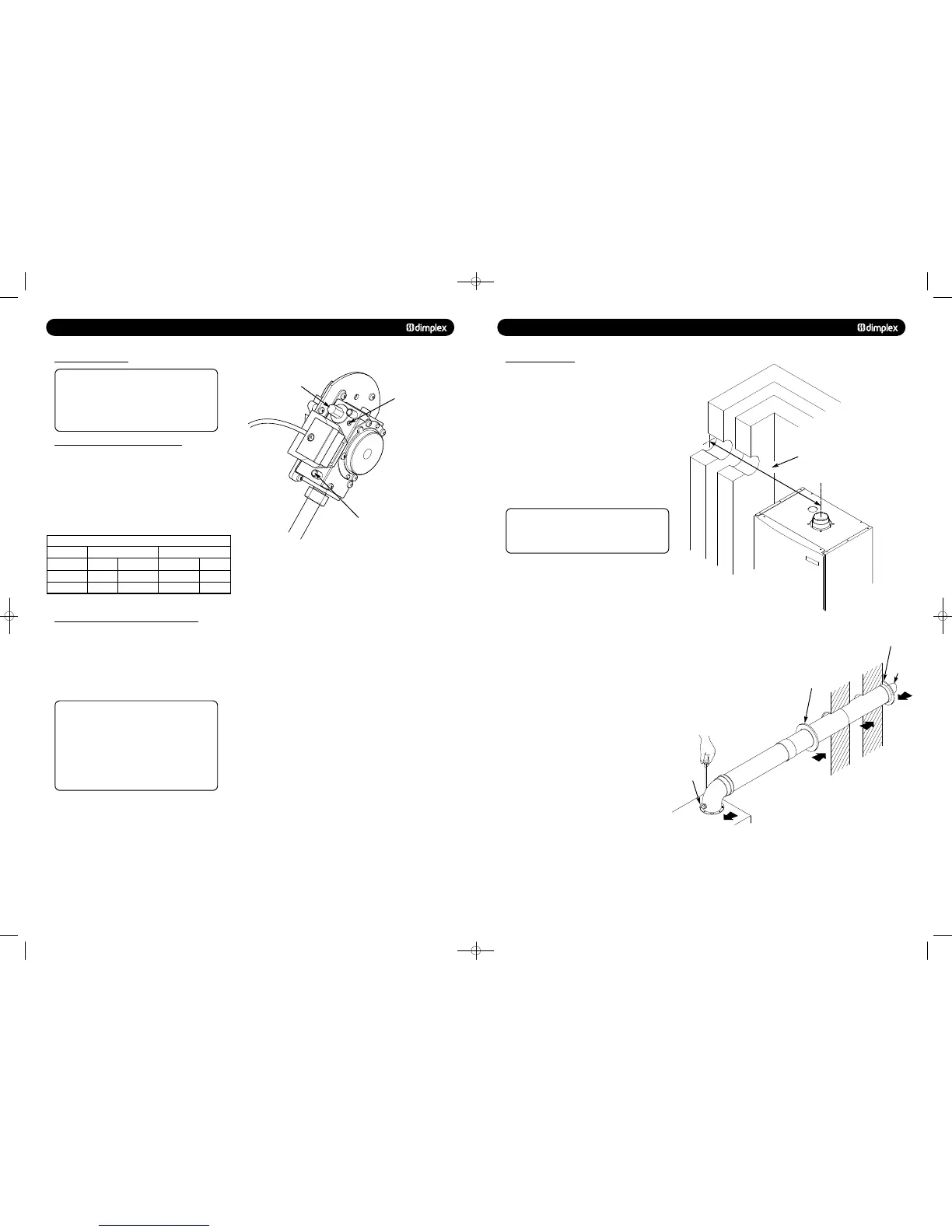

2. Measure the required flue length as shown in Fig. 34. Refer

to section 8 to determine whether any extension kits are

required. Installations using only the standard ducts or

standard ducts with straight extensions are described in this

section. Installation instructions for all other flue systems are

included in the various flue kits.

3. Ensure that all (inner and outer tube) sealing rings are

provided and assemble the air/flue ducts as shown in the flue

instructions.

4. Ensure that the flue and air seals are correctly fitted before

assembly and that each section is fully engaged.

NOTE: NEVER CUT THE SWAGED END. Where necessary the

plain ends of the extension ducts may be cut. Always

ensure that the cut is square and free of burrs or debris.

It is essential that the terminal is fitted the correct way up.

See flue kit instructions (i.e. rain shield at the top).

INSTALLING THE AIR/FLUE DUCT FROM INSIDE TH

Detailed installation instructions are included in the flue kit.

(Flue hole diameter 130mm).

1. Push the terminal through the wall taking care to ensure

that the terminal is the correct way round and the external

wall-sealing ring does not become dislodged.

2. Assemble the flue system extension ducts as necessary,

referring to Fig. 35.

3. Pull the flue system towards the appliance to seat the

external sealing ring against the outside wall, ensuring that the

duct joints are not disturbed.

4. Use the internal sealing ring to make good the internal hole

and check that the terminal is correctly located on the outside

wall. Where possible this should be visually checked from

outside the building (Fig. 35).

5. Finally locate and secure the elbow to the appliance using

the four screws provided.

INSTALLING THE AIR/FLUE DUCT FROM OUTSIDE THE BUILDING

Detailed installation instructions are included in the flue kit.

Flue hole diameter 100mm - 110mm.

1. Secure the flue elbow with seal to the appliance using 4

screws.

2. Fit the external wall sealing ring over the flue and then from

outside the building, push the flue system through the wall

taking care to ensure that the terminal is the correct way

around.

3. Loosely fit the internal wall sealing ring over the inside end

of the flue.

4. Assemble the flue system extension ducts as necessary

referring to the flue kit instructions and fit to the elbow.

5. Fit the flue terminal to the flue system, ensuring that the

duct joints are not disturbed and that the external sealing ring

is seated against the outside wall.

6. Finally use the internal sealing ring to make good the

internal hole. Check that the external wall sealing ring and the

terminal is correctly located on the outside wall.

© Dimplex Boilers 2008

‘L’ = Total flue length from flue outlet

centre to outside wall face

Align the assembled

flue system elbow to

appliance and secure

Slide internal wall

sealing ring to wall to

form a good seal

Insert assembled flue

system from inside the

room. External wall

sealing ring opens

External Wall

Sealing Ring

Terminal

To p

Internal Wall

Sealing Ring

751262 MANUAL 19/10/10 08:41 Page 23

Loading...

Loading...