0020148679_00 - 11/12 - Glow-worm

- 14 -

INSTALLATION AND SERVICING

EN

7.2 System failure codes

The fault status may be “inactive” (disappeared) "active" (still

aff ects the installation).

The installation can operate partially with a fault “active”. It is not

necessarily “blocking”. An alarm (not supplied) can be added to

the installation to signal certain faults. System failure codes are

described in the table of system failure codes (see chapter 10.2).

7.3 Control unit eBUS failures

Description Cause Solution

No display on

screen

The power

supply is faulty.

The fuse is

damaged.

Make sure that the electricity

supply has not been interrupted.

Check that 230V supply is turned on

and present.

Check the position of the control

unit switch.

Check the control unit’s fuse.

7.4 Resetting the control unit eBUS

This function allows you to reset the control unit (factory setting).

This restarts the installation assistant.

b

Caution.

• The resetting of factory settings is irreversible. Any

customised configuration of the control unit will be

lost.

∙ Simultaneously press the buttons

for 10 seconds.

∙ Confi rm by pressing

ok .

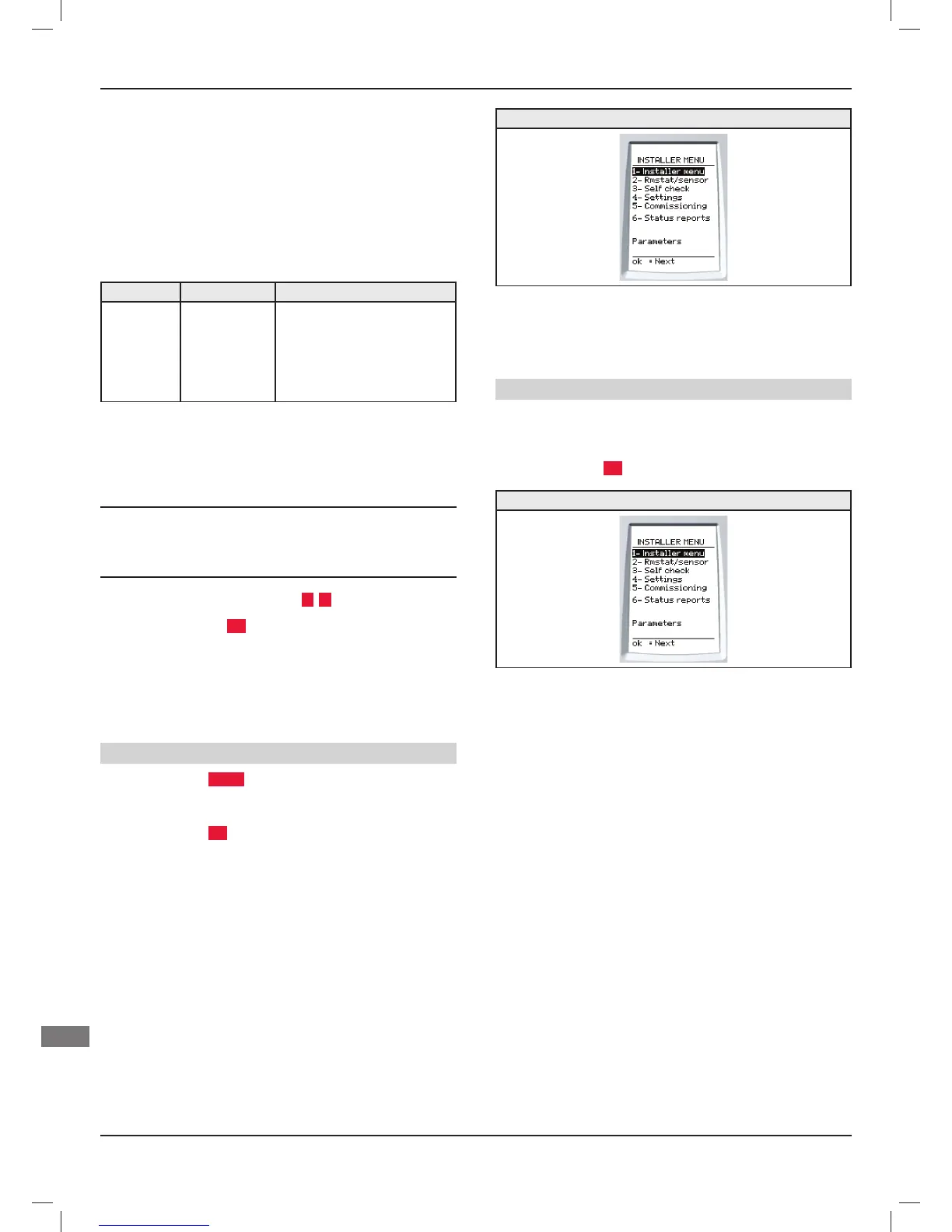

7.5 Installation menu

The installation menu is still accessible after commissioning.

Menus and functions are described in the table of menus and

functions (see chapter 10.1).

Access to the installation menu

∙ Press the button

menu for 7 seconds.

∙ Enter the installer access code 96.

∙ Press the button

ok to confi rm.

Individual installation

- Check the proper operation of external control items (room

thermostat, outside sensor...).

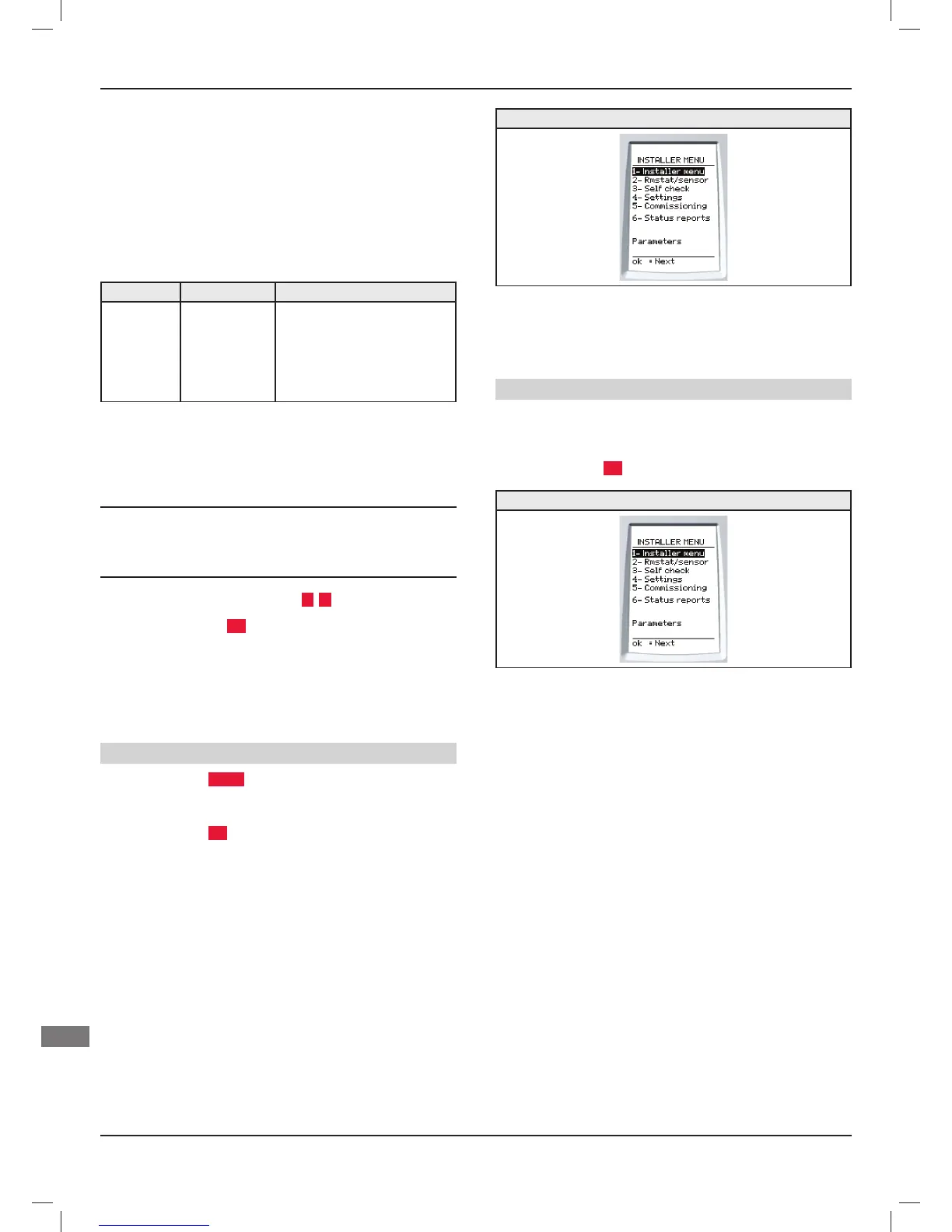

7.6 Maintenance menu

Access to the maintenance menu

∙ Press the “menu” button for 7 seconds.

∙ Enter the installer maintenance access code 35.

∙ Press the button

ok to confi rm.

Individual installation

The maintenance menu includes the installation menu function,

plus 2 additional functions:

- "System tests", within the maintenance menu,

- "After sales service Info", in the options.

7.6.1 System tests

This menu allows you to test the operation of all the appliances

and the system (boiler, HP, valve,) present in the installation.

Each element can be controlled centrally by activating its normal

start-up function or by individual component.

By entering the test menu, the control unit displays the following

message: “the system is currently stopped" No further heating

control operations are aff ected. Control is resumed upon exiting

the menus.

Loading...

Loading...