Supplied By www.heating spares.co Tel. 0161 620 6677

44

13 Servicing

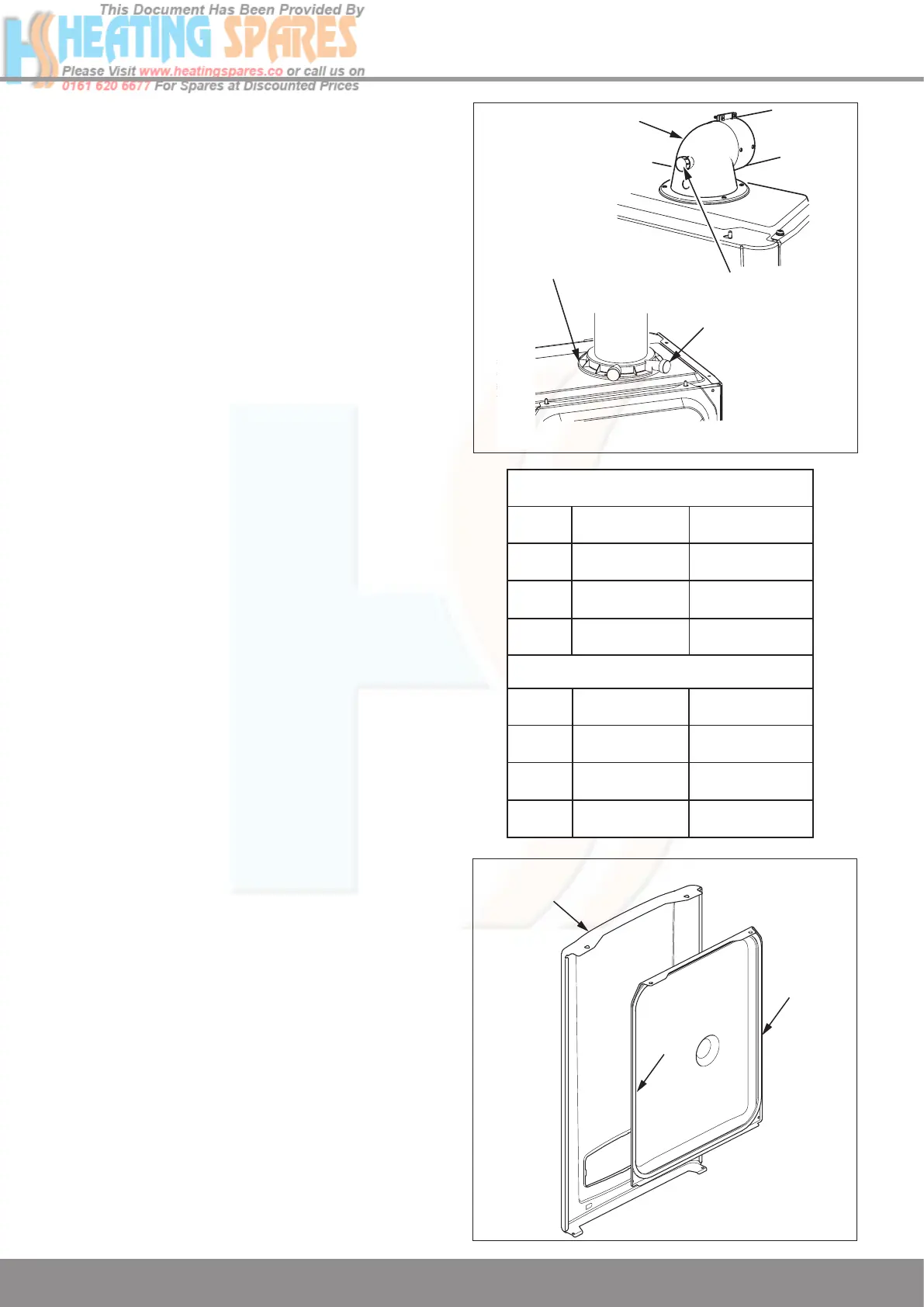

13.7 Combustion Check

With the appliance operational connect the CO

2

combustion

analyser to the test point, see diagram 13.9.

IMPORTANT: Remember to replace the cap on

completion of the test.

Check the burner %CO

2

, at maximum rate(open a hot water

tap fully to generate a demand). The values are shown in the

“CHECK” column of the table and if the reading falls within

the range, disconnect the analyser, fit the test point cap and

return to functional checks - gas rate.

If adjustment is required remove the front and inner casing

panels, see diagram 13.1. Taking care not to touch any

internal components, proceed as follows:

Press the “reset” button on the controls fascia, release

and immediately pr

ess and hold in the “+” button. After

approximately 5 seconds “Hi” will be displayed. Pressing

the mode button when “Hi” is selected will force the boiler

to maximum rate, the display will flash between “Hi” and the

“default display” this will indicate the boiler has been forced

to maximum.

Adjust the %CO

2

to the value shown in the “SETTING”

column of the table with the throttle, see diagram 12.5.

(Rotate anti-clockwise to increase).

To exit the check sequences press the “mode” and “+”

buttons simultaneously, this will reset the boiler to the default

display.

Check the burner % CO

2

at minimum rate is as shown in the

“CHECK” column of the table.

Press the “reset” button on the controls fascia, release

and immediately press and hold in the “+” button. After

approximately 5 seconds “Hi” will be displayed. Pressing the

“+” or “-” buttons will cycle between “Hi” and “Lo”. Pressing

the mode button when “Lo” is selected will force the boiler

to minimum rate, the display will flash between “Lo” and the

“default display” this will indicate the boiler has been forced

to minimum.

Adjustment of the %CO

2

at minimum rate is very coarse

so carefully adjust the %CO

2

to the value shown in the

“SETTING” column of the table with the offset adjustment,

see diagram 12.5 and %CO

2

Table (Rotate clockwise to

increase).

To exit the function press the “mode” and “+” buttons

simultaneously, this will reset the boiler to the default display.

13.8 Gas Rate Adjustment

This appliance incorporates a pre-mix burner and cannot be

adjusted, however, it is acceptible to set the combustion rate

with a gas analyser as described in section 13.7.

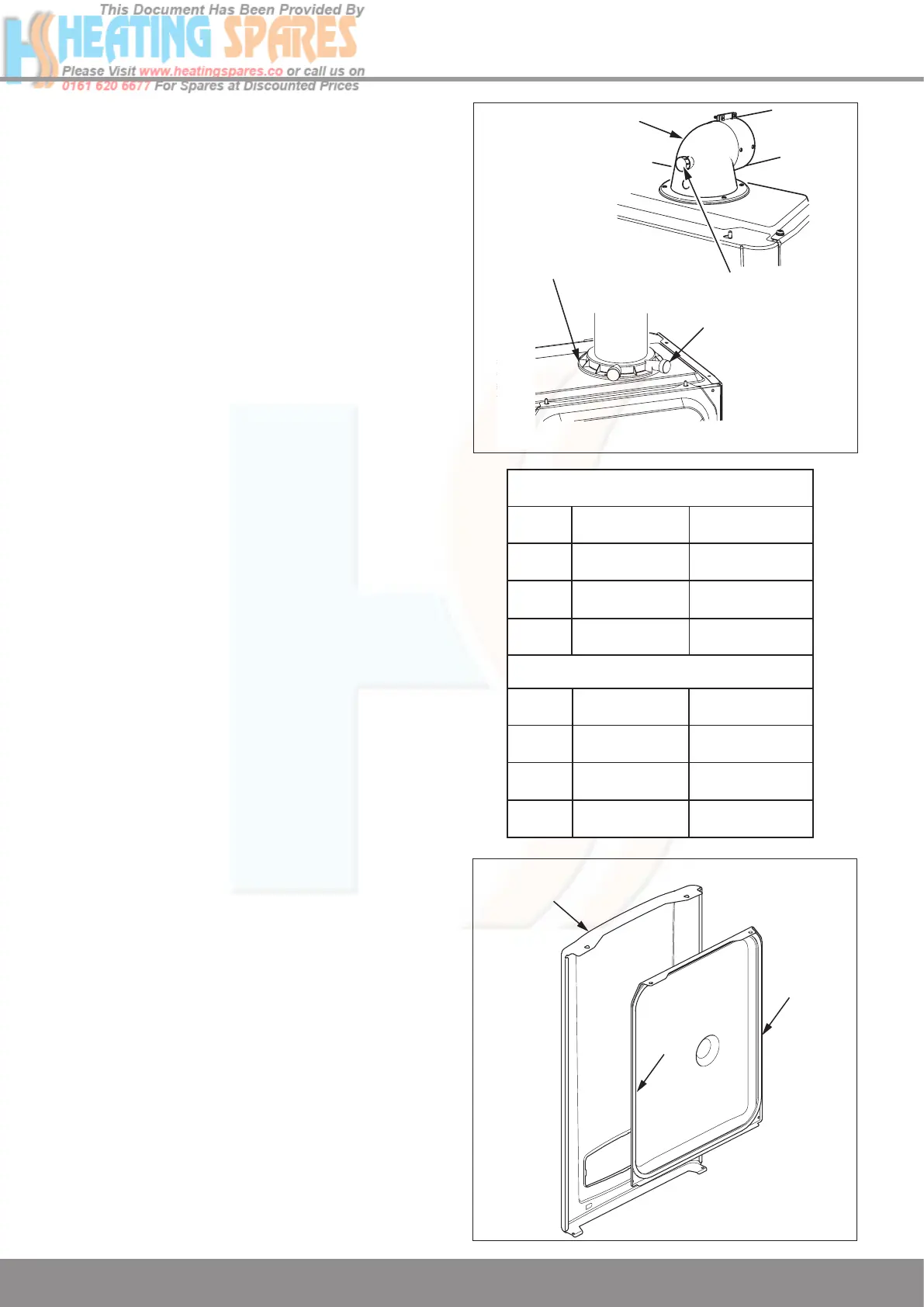

13.9 Inner Casing Panel Seal check

Check the condition of the seal, if worn or damaged remove

the seal and thoroughly clean the casing surface before fitting

the new seal, see diagram 13.10.

Refit the inner casing panel.

NOTE: Ensure the seal is fitted correctly giving an airtight

joint.

13.10 Service Completion

On completion of the service the “Benchmark” Service

Record should be completed.

FLUE ELBOW

COMBUSTION

ANALYSER

SAMPLE

POINT

VERTICAL FLUE

ADAPTOR

Diagram 13.9

13566

10063

INNER

CASING

PANEL

FRONT

CASING

PANEL

SEAL

Diagram 13.10

MODEL

24cxi

30cxi

38cxi

G31 BURNER % CO2

CHECK

(case on)

SETTING

(case off)

9.2 to 10.2

10.0 to 11.0

9.2 to 10.2

10.0

10.5

9.8

+ 0.0

- 0.9

+ 0.3

- 0.7

+ 0.2

- 0.8

MODEL

24cxi

30cxi

38cxi

G20 BURNER % CO2

CHECK

(case on)

SETTING

(case off)

8.5 to 9.6

8.5 to 9.6

8.5 to 9.3

9.1

9.1

8.8

+ 0.2

- 0.5

+ 0.2

- 0.5

+ 0.2

- 0.5

Loading...

Loading...