Technology for safety

16

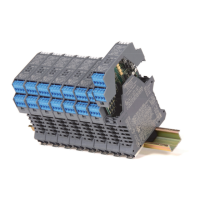

D1000 series - Intrinsically Safe Isolators

Approvals and Certifications

Intrinsically Safe products

G.M. International’s products have been granted IS certificates from the most credited Notified bodies in the world.

Certificates are available for ATEX (Europe), IECEX (International), Russian and Ukrainian standards, USA and Canada.

Certificates have been integrally scanned and are available for download from our website.

SIL Certifications according IEC 61508 and IEC 61511

G.M. International offers a wide range of products that have been proved to comply with the most severe quality and safety requirements.

IEC 61508 and IEC 61511 standards represent a milestone in the progress of industry in the achievement of supreme levels of safety through

the entire instrumented system lifecycle.

The majority of our products are SIL certified; reports and analyses from TUV and EXIDA are available for download from our website.

Marine Type Approval

G.M. International offers Type Approval Certificates for its line of Intrinsically Safe Isolators D1000 Series and Power Supplies for use in

Marine and Offshore applications.

Certificates have been released both by Korean Register of Shipping and Det Norske Veritas.

Company Quality System

G.M. International’s Production Quality System is certified by Det Norske Veritas (Norway) to be compliant with ATEX 94/9/EC Directive

and ISO 9001/2000.

This means our production facilities are periodically re-assessed throughout the whole manufacturing process, to ensure that the highest quality

standards are met.

Storage

If after an incoming inspection the unit is not installed directly on a system (parts for spare or expansion with long storage periods) it must be

conveniently stocked. Stocking area characteristics must comply with the following parameters: Temperature: –20 to +60 °C, the –45 to +80 °C

in the data sheet is meant for limited periods, mainly to arrange for air transport, -10 to +30 °C are preferred.

Humidity: 0 to 90 %, long period high humidity affects the package integrity, 0 to 60 % humidity is preferred.

Vibration: no prolonged vibration should be perceivable in the stocking area to avoid loosening of parts or fatigue ruptures of components terminals.

Pollution: presence of pollutant or corrosive gases or vapors must be avoided to prevent corrosion of conductors and degradation of insulating

surfaces.

Disposal

The product should not be disposed with other wastes at the end of its working life. It may content hazardous substances for the health and the

environment, to prevent possible harm from uncontrolled waste disposal, please separate this equipment from other types of wastes and recycle it

responsibly to promote the sustainable reuse of material resources. This product should not be mixed with other commercial wastes for disposal.

In each case the product must be disposed in compliance with the applicable laws and guidelines of the respective country.

Maintenance and Repair

Series D1000 modules do not require particular maintenance under normal operating conditions. They are designed to operate trouble free and

with high stability for long time. If a unit is found not meeting specifications or in a failure condition then it requires recalibration or servicing.

Any repair made by unauthorized personnel may completely invalidate the safety characteristics of the card. Repair not made by GM. International

is prohibited. If a barrier failure condition is actually found, replace the defective card with a good one and send it for repair to the nearest authorized

representative of GM International.

Loading...

Loading...