1 0991 486

EN

-

29.09.2016

ENG

DLV

VALVE MANUAL

I

NSTALLATION

,

U

SE AND

M

AINTENANCE

5 / 11

DLV are manifactured in different sizes and can be used for the following range(see the tab. 1).

Type

Max

interv.flow

Nominal

flow

Working

press.

Working

temp.

Viscosity Tens.DLV Power

Emerg.

Pw.

l/min bar °C cSt Vdc

Vac W Vdc

DLV A3 – ¾”

45 8 - 45

12 - 45 5 - 70

14-290

(ISO VG 46

I≈120)

24-12

48-12

80-12

90-12

110-12

180-12/24

110

220

230

30

12 24

DLV A3 - 1” ¼

210 15 - 210

30

DLV A3 - 1” ½

430 25 - 430

30

DLV A3 - 2”

600 30 - 600

45

Tab. 1

1.2 DELIVERY PACKAGING

Upon picking up the material,before signing the delivery,be care the goods match the packing list and the order

list.

The packing list should includes:

- Installation use and maintenance manual

- DLV device (factory assembled)

- Connection fittings

- Cartboard box

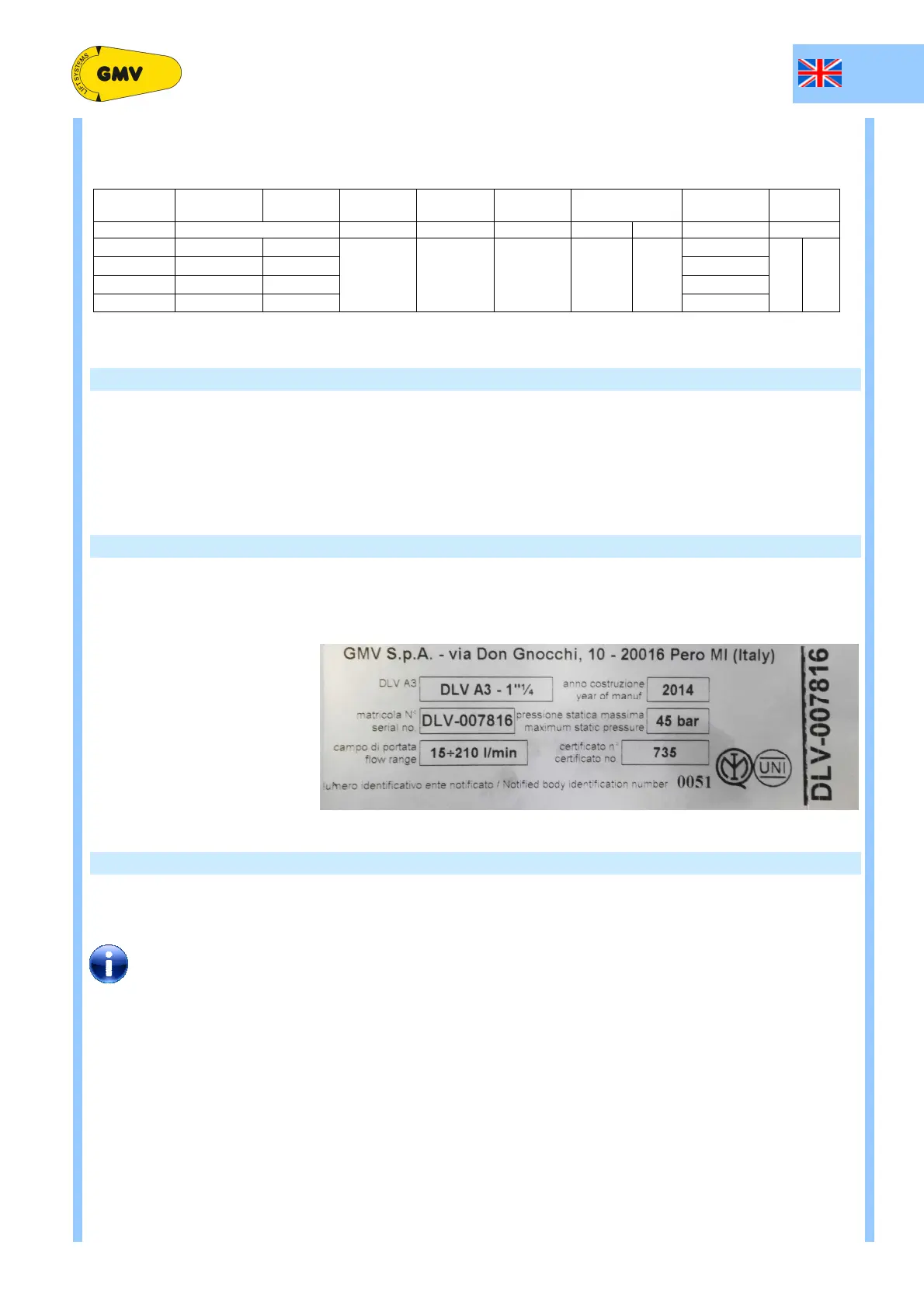

1.3 IDENTIFICATION PLATE

The indentification plate with the main factory data (see picture below), is directly placed on DLV.

The plate should include:

- Type of DLV device

- Serial number

- Year manifacturing

- Flow range

- Max static pressure

1.4 THE FLUID

The hydraulic fluid is very important for an hydraulic lift

Especially in systems with medium or intensive traffic,choosing a good fluid increases the temperature range of

comfortable working and enhances the service life of the components.

When we choose the fluid we must take into account both the characteristics of the elevator

(temperature , power unit ventilation room, amount of trafic) and the characteristics of the fluid

(temperature-viscosity).In case of replacement,follow the local pollution.Waste should be placed in a

proper box to protect the environment.

Loading...

Loading...