6

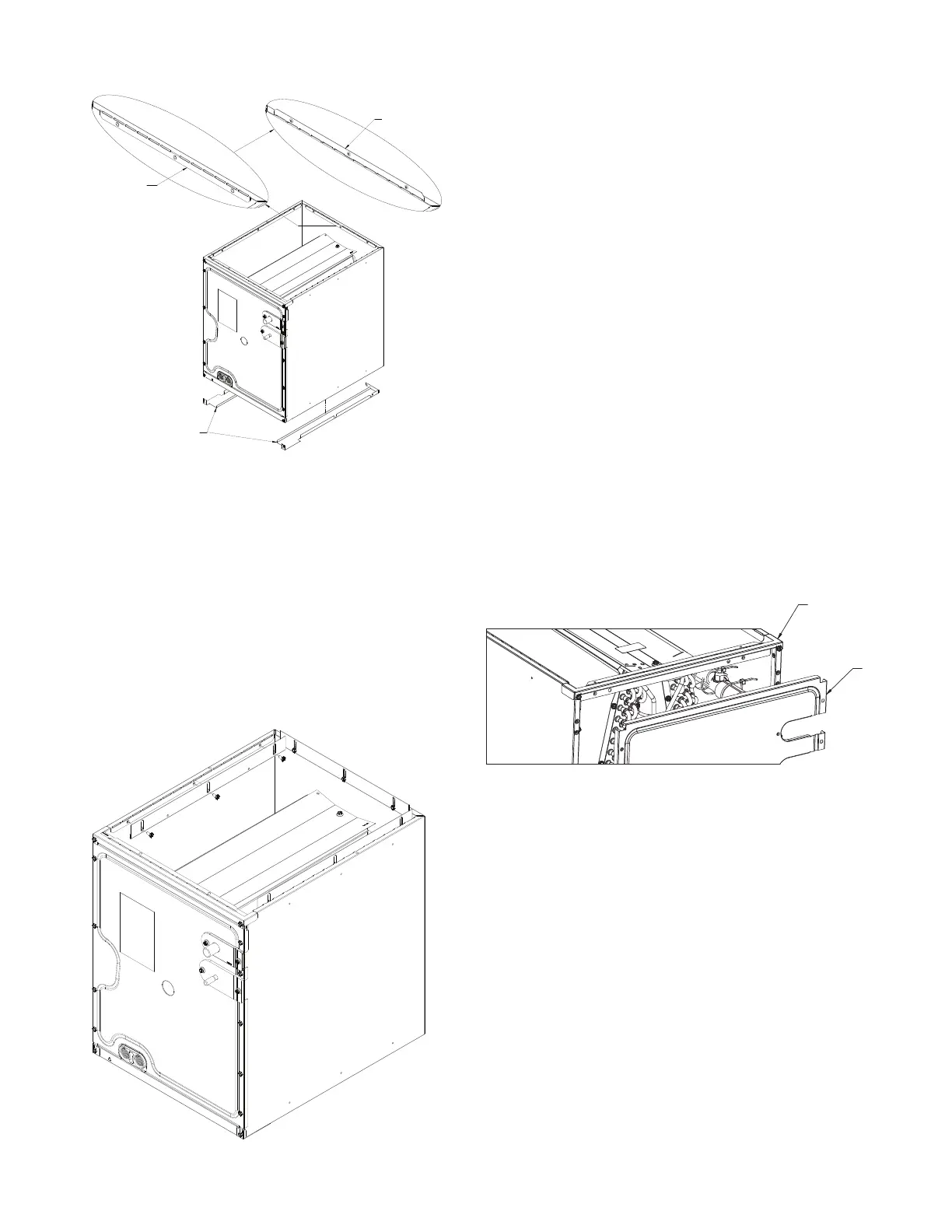

FILLER PLATE

FLANGE BENT DOWN

FLANGE UNFOLDED UP

Figure 6

2. A duct ange kit can also be purchased from your dis-

tributor. (See Figure 7)

• 14 inch chassis - CLDUCTFLGA

• 17.5 inch chassis - CLDUCTFLGB

• 21 inch chassis - CLDUCTFLGC

• 24.5 inch chassis - CLDUCTFLGD

Figure 7

11. Filler Plates

Filler plates are supplied on all 17.5, 21, & 24.5 inch chassis

to be used for adapting the unit to a furnace one size smaller.

If the plenum and furnace openings are the same size, the

ller plates must be removed. See Figure 6.

12. Return Ductwork

DO NOT TERMINATE THE RETURN DUCTWORK IN

AN AREA THAT CAN INTRODUCE TOXIC OR OBJEC-

TIONABLE FUMES/ODORS INTO THE DUCTWORK.

13. Sealing Along The Panel Gap

IMPORTANT NOTE: To prevent cabinet sweating and airow

leak, apply eld provided insulation tape along all joining

surfaces between the coil, gas furnace, duct work and panels.

See Figure 8.

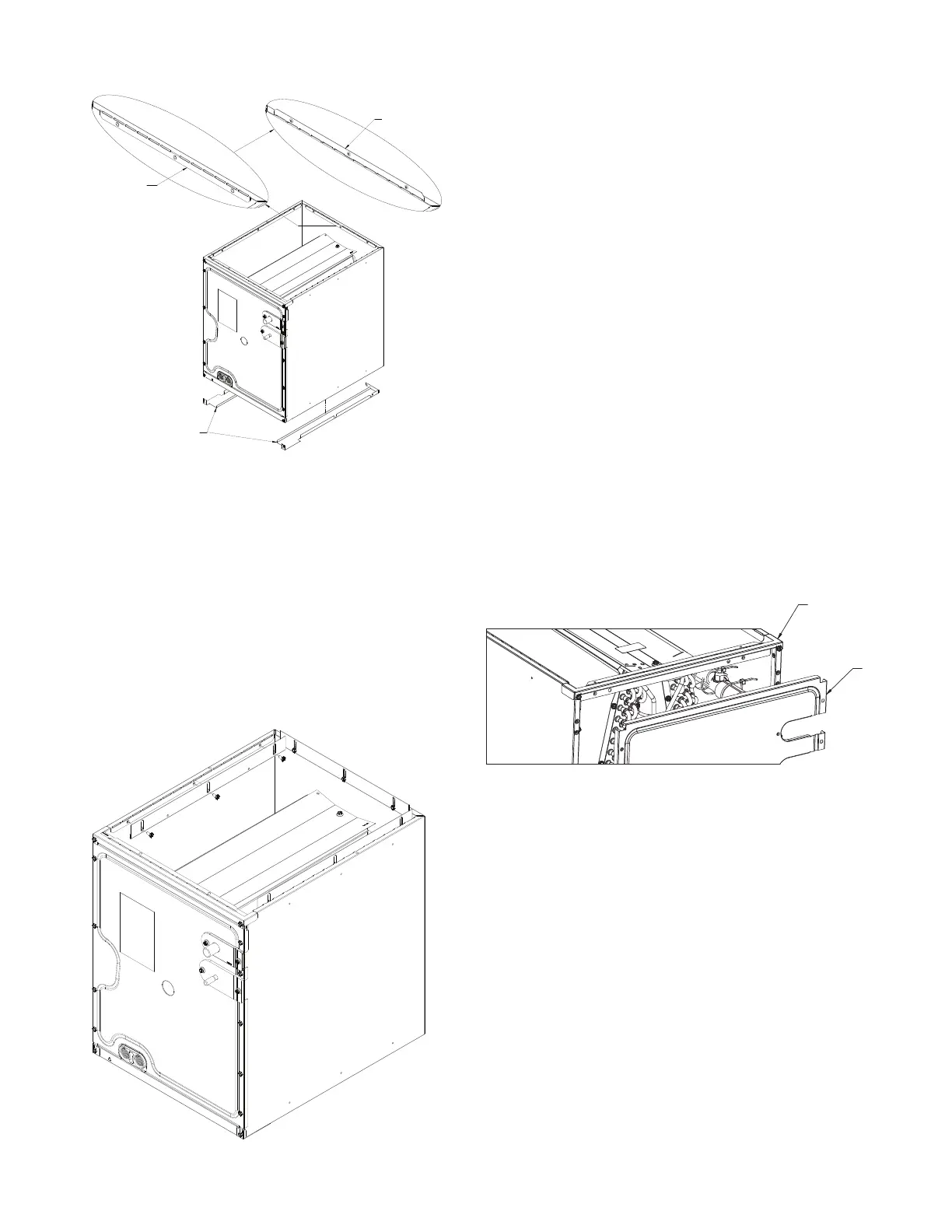

14. Removing Coil from Cabinet

In an event of removing taller coils from cabinet to service or

replace; remove access panel, remove top tie rail to allow the

coils to slide out of the cabinet.

After service or replacement slide the coil back in the cabinet

and secure the top tie rail and re-install access panel.

See Figure 9.

TOP TIE

PANEL

Figure 9

Clean Comfort brand UV coil puriers also can be purchased

from distributor. Maximum UV lamp diameter to be used per

delta plate knockout design is 1.375” to reduce the possibility

of air leak.

Refer to UV coil puriers product specication and installation

manual for additional details.

Loading...

Loading...