6

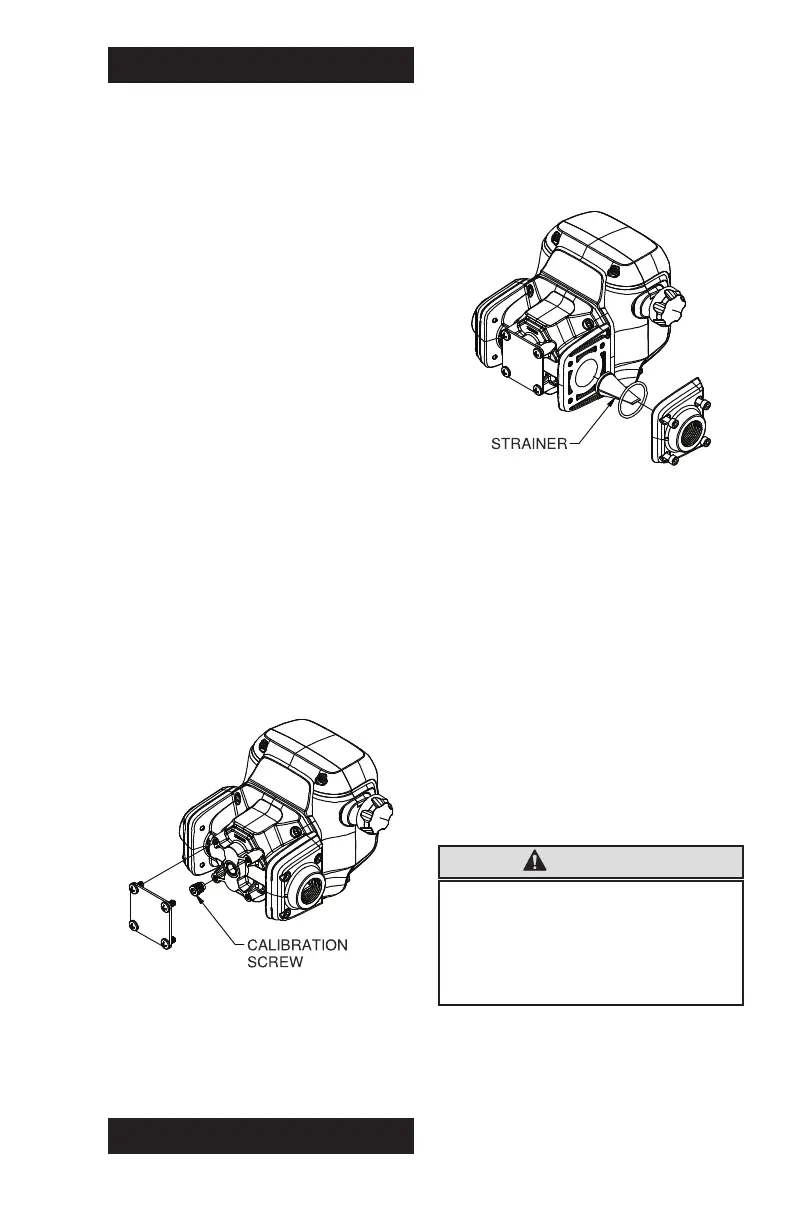

CALIBRATION

The meter is accurately calibrated at the

factory for use with diesel fuel� Due to

differences in viscosity and ow rates,

the meter may require recalibration

to measure other fuels or to adjust

for inaccuracies� A gear replacement

kit is available (PN 139500-15, see

Illustrated Parts List section) to

convert the meter to unleaded fuels�

1� To adjust the calibration of the me-

ter, gain access to the calibration

screw by performing the

following: (see Figure

5a

)

2� Remove the back plate and the

(4) screws retaining it� The O-ring

seal under the plate must not be

damaged�

3� Using the 5mm hex L-wrench

provided with the meter, adjust the

calibration screw as required�

4� Note: The calibration screw set-

ting may have been adjusted at

the factory� The gasoline setting

is approximately fully closed (turn

clockwise)� Do not overtighten the

screw against the seat�

figure

5a

5� Reinstall the plate, (4) screws

and the O-ring seal if removed�

Tighten (4) screws to 42-46 lb-in

[4�7-5�2 N

•

m] torque�

MAINTENANCE

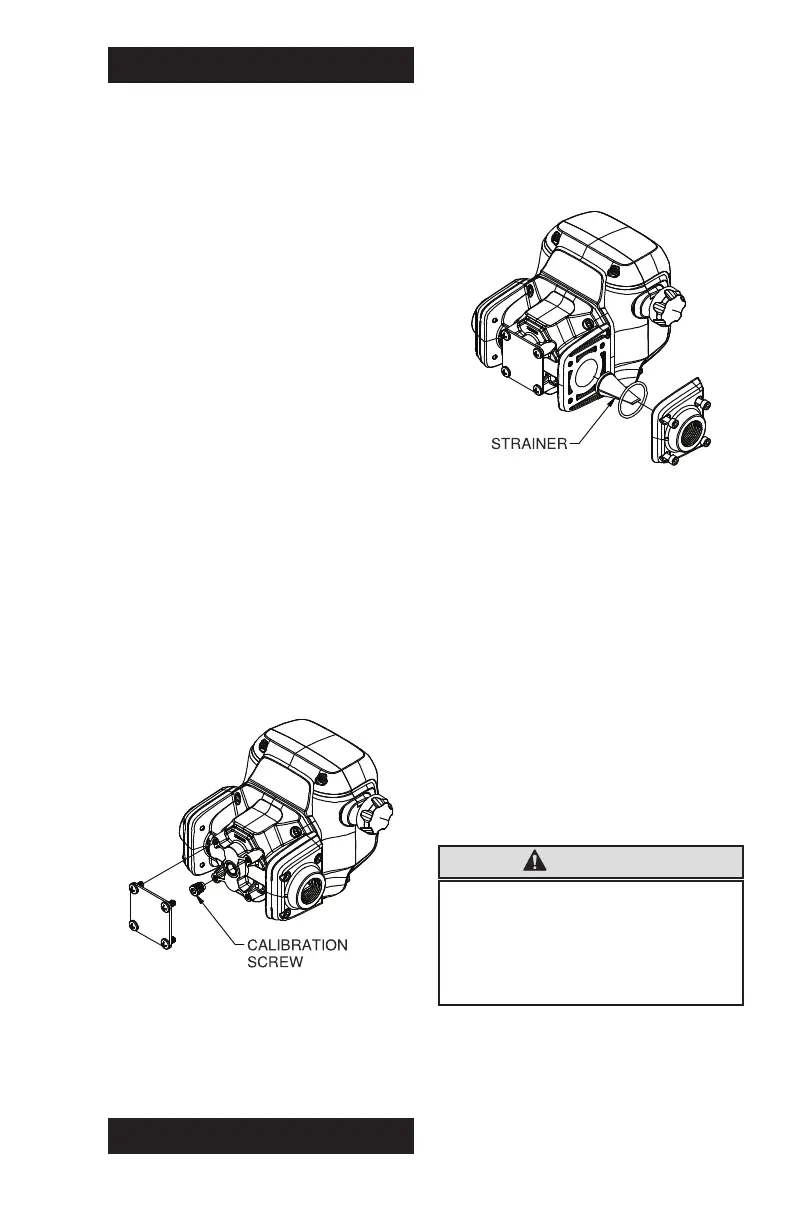

The meter’s strainer should be cleaned

at regular intervals, especially if reduced

ow is encountered�

Clean or Replace Strainer

1� Remove the socket screws at the

inlet fitting� Remove the fitting, O-

ring and strainer� (see Figure 5

b

)

figure 5

b

2. The strainer rim is pressed into the

housing inlet but can be removed

by carefully grasping the end with

pliers and pulling with a wiggling

motion until free�

3. Using a fine brush, clean the strainer�

Replace the strainer as necessary�

4� Wipe the housing inlet and re-

install the strainer by pressing it

into place with the end of a 1”

pipe nipple (or 1" electrical conduit

for QM40) or similar tube tool using

light hammer taps�

CAUTION

The mesh strainer must always be

installed when operating the meter;

otherwise, particles may enter the

meter chamber and disrupt the

operation of the oval gears�

5� Wipe the fitting and O-ring groove

clean� Coat the O-ring with oil or

light grease and seat into the

fitting groove�

6� Reinstall the inlet tting and screws�

Tighten screws to 42-46 lb-in

[4�7-5�2 N

•

m] torque�

Loading...

Loading...