NOTE:

To install a200 Series

Reel

into a K

-

Frame Enclo

-

sure, part no. 206

-

604, order the

Hose

Retainer

Kit, part no.

220-897. See manual 307-844.

supplied with the

kit,

for installation instructions.

1.

Select the reel bank mounting location.

If

the ceil

-

ings are very high, Suspend a suitable support struc

-

ture for the reels,

so

the hoses will be long enough

to

reach your service area.

The

reel bank should be mounted in a one

-

lift service

See

Fig

1.

In

a two

-

lift bay, mount the bank equal dis-

bay, at least

6

ft

(1.9 m) from the center line

of

the

lift.

tance between the lifts.

A

bank of all motor

oil

reels

should be mounted about 5

ft

(1.5 m) from the center

bracket

to

secure the mounting base to an I

-

beam

is

of

the lift, toward the front of the

lift

rails.

A

mounting

available.

See

ACCESSORIES,

page 25.

-.

6'

(1.9

m minimum

JOR.

1 UFTY

I

CENTER

BETWEEN

TWO

LIFTS

303

CAUTION

Be

sure the mounting surface is strong enough

to

support the reels. the weight of the lubricants, and

the stress caused by hard pulls on the service

hoses.Seethebackcoverforthedryweightsofthe

hose reel assemblies.

2.

If

you are

NOT

installlng

a

hose reel enclosure,

25 and install the frame (303) and base plate (304) as

OrdertheREELMOUNTlNGBASEpartsiistedonpage

shown in Fig 2.

reel base (103 or 304) to the mounting channel

(A),

It

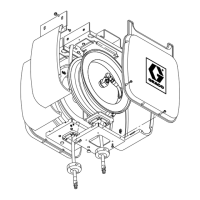

you are lnstalllng the hose reel enclosure,

bolt the

using the lockwashers

(B)

and screws (C) which are

supplied with the mounting channel. See Fig 3.

3.

If

you are Installing permanent supply lines,

drill

1.5

in.

(38 mm) diameter

holes

through the ceiling on

the inlet side of the reels.

4.

Slide the hose reel onto the mountlng base

and

(105 or

301).

Tighten the screw firmly.

See

Fig 3.

install the hold

-

down plate (104

or302)

and capscrew

5.

Connect the supply line

to

the inlet hose of the reel.

NOTE:

All

other hose reels listed in this manual are

supplied with a Hose inlet Kit.

6.

Adjust the sprlng tension

of

the reel.

NOTE:

If

you are installing a hose on a bare reel, connect

the Service hose to the swivel (31). Then wrap

the

fully and latch

it.

Wrap one or

two

loops around

hose

loosely around the flange. Extend the hose

the hose reel, then retract the hose again.

Check the spring tension: the hose must pull out fully

and retract fully. Wrap

ONE

more loop, extend the

hose, and latch

it.

Do

this as many times

as

necessary

until the spring has the desired tension.

CAUTION

Do

not put.so many loops onto the reel that the

spring winds

up

tigMly before the hose is fully

extended.

A

spring that is wound

too

tightly stops

rotating before the hose

isfullyextended. That puts

excessive

strain

on

the hose and reel sprina and

could damage the reel.

To

decrease tekion,

remove two or three loops of hose from the reel.

I

7.

Install

the

hose stop

(D)

and dlspenslng valve.

Po

-

sition the hose stop

so

the hose extendsfar enoughfor

all operators

to

reach

it.

See

Fig

3.

Loading...

Loading...