Fluidemittedunderhighpressurehomleaksorrupturedcompo

-

nents can penetrate the skin and cause extremely serious bodily

injury, inciudingthe need for amputation.

AIs0,fluid injected into

or splashed into the eyes can cause serious damage.

The

MMMUM

WORKiNG

PRESSURE

Of

your hose reel assem-

System Pressure

biy

is determined

by

the lowest

-

rated component in the assem

-

bly. The HOSE REEL MODEL charts on pages

4

to

6

give the

maximum working pressure of the assemblies listed there.

If

you

are adding a

sewice hose and dispensing valve to a bare hose

reel,

be

sure you know the maximum working pressure of all

components1

To reduce the risk of serious bodily injury, including fluid

Pressure

Rellef Procedure

from moving parts. always follow this procedure whenev-

injection. splashing in the eyes or

on

the skin, or injury

er you shut

off

the pump, and before inspecting, remov

-

ing, cleaning or repairing any part of the pump or system.

2.

Close the supply pump's bleed

-

type master air valve

1.

Close the supply pump's air regulator.

3.

Open the dispensing valve until pressure is fully

(required in pneumatic systems).

If

you suspect the dispensing valve, extension or grease

relieved.

fitting

coupier is dogged, or that pressure has not been

fully relieved after foiiowing

all the steps above, VERY

SLOWLY

lwsen the couoier or hose end CouDiina and

allow pressure to be relieved gradually, then

ibs&

the

part completely. Now clear the clog.

Do

not modify any part of the dispensing valve. Only use exten-

Dispensing Valve Safety

siansandgreasefittingcouplerswhicharedesignedforusewith

your dispensing valve. Modifying parts can cause a malfunction

and result in serious bodily injury.

Flexible Extension

Safety

extension you are using. Never exceed that pressure, even

if

Be

sure you knowthe maximum working pressure of the flexible

your dispensing valve

and/or pump

is

rated for higher working

pressures.

..

Never use a low pressure, flexible extension, designed for low

pressure dispensing valves or hand

-

powered lubricatingequip

ment,

on

a high

-

pressure dispensing valve.

Never attempt to force the lubricant into

a

fitting1

If

the lubricant

is not flowing, STOP DISPENSING IMMEDIATELY.

The

fitting

may be clogged. Forcing lubricant may cause excessive back

pressureintheflexibieextension,whichcouidcauseittoNpture

and result in serious bodily injury, including

fluid

injection and

eye injury.

Grease Fitting Coupler Safety

Use

extreme caution when cleaning or changing grease fitting

couplers.

if

the coupler clogs while dispensing, STOP

DIS

-

PENSING IMMEDIATELY.

Follow

the Pressure Relief Proce-

buildup around the coupler until pressure is fully relieved.

dure

,

at left. Then remove the coupler to clean it. Never wipe

off

General Safety

Check the operation of all equipment safety devices before each

use.

NEVER point the dispensing valve at anyone or any

parl

of

the

body.

NEVER put your hand or fingers over the grease fitting coupler.

NEVER alter or modify any part of this dispensing equipment;

doing

so

could cause

it

to malfunction.

CHECK

all dispensing equipment regularly. Repair or replace

worn or damaged parts immediately.

NEVER

try

to stop or deflect leaks

with

your hand or body,

Medical

Treatment

. . .

-

-.

-

-.

.

.

-

-

..

.

.

-. .

.

If

any fluid appears to penetrate your skin, get EMERGENCY

.

MEDICAL CARE AT ONCE.

DO

NOT TREAT AS A SIMPLE

CUT1

Tell

the doctor exactly what fluid was injected.

Note

to

Physician: injection into the skin is a traumatic

injuw

It

is important tolreat the injury surgically

as

soon

as

possl-

ble.DonotdeiaytreatmenttoresearchtoxicityToxicityisacon-

cern with some exotic coatings injected directlyinto the blood

stream. Consultation with a plastic surgeon or reconstructive

hand surgeon may be advisable.

USE

EXTREME CAUTION WHEN HANDLING THE SPRING!

The spring, which is located behind the flange,

isALWAYS under

great tension and could be propelled from the lower flange

with

TO reduce the risk of serious bodily injury when replacing the

enough force to cause serious bodily injury.

spring, use extreme caution when removing the top reel flange.

flange to expose the spring.

Be sure the reel

is

laying flat, and then carefully lift

up

on

the

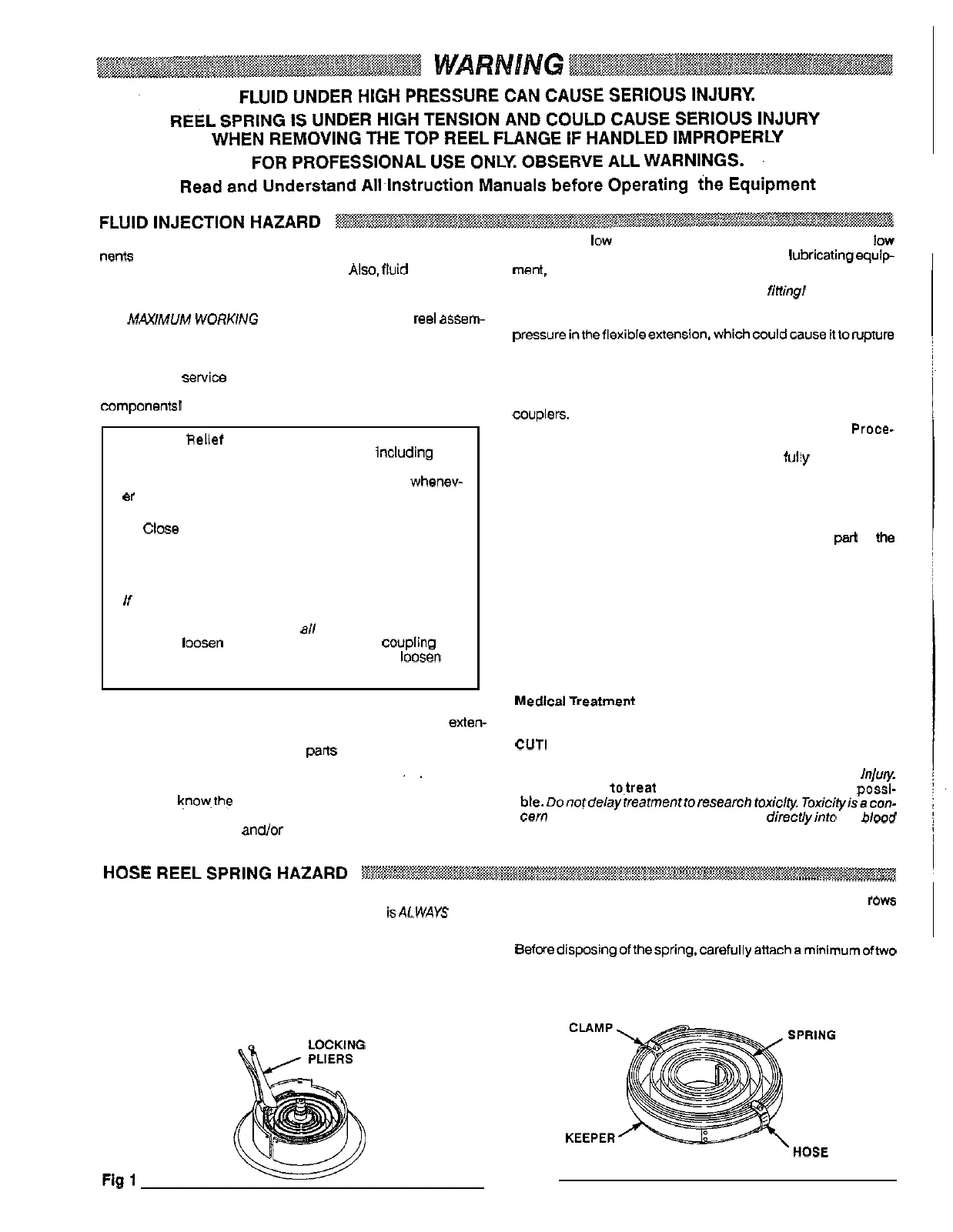

ALWAYS use locking pliers to compress and hold several

row

of the spring together when removing and when installing a

spring. See Fig

1.

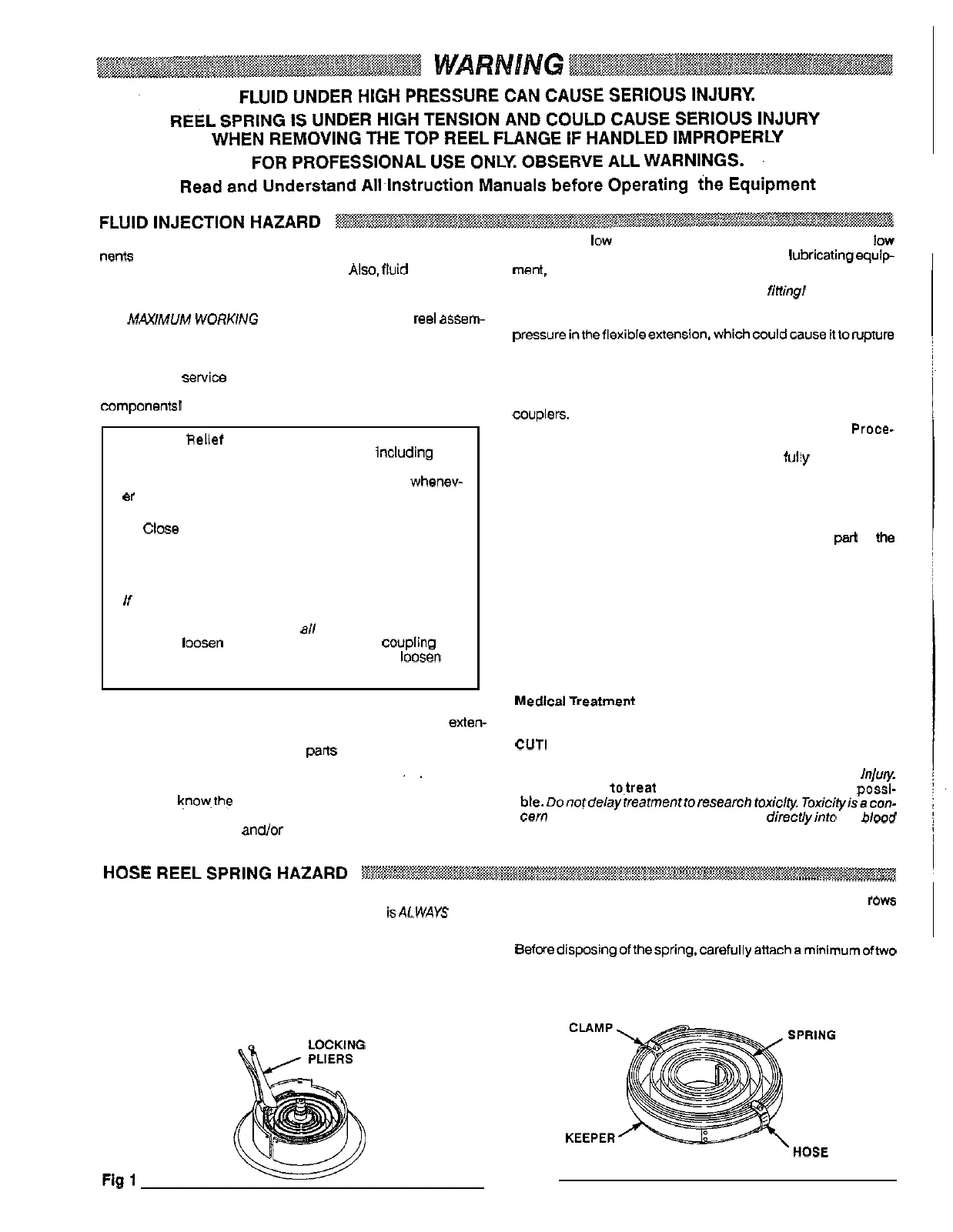

Beforedisposingofthespring,carefullyanachaminimumoftwo

hose clamps around the keeper and spring bands as shown in

Fig

2.

HOSE

Fig

2

CLAMP

307

-

694

3

Loading...

Loading...