Lubrication

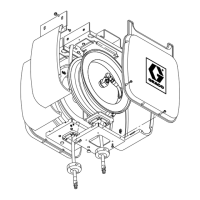

(See Fig

5)

to relieve pressure from the service hose. Every six

Shut

off

the air or fluid supply. Open the dispensing valve

months, apply one or

two

drops of light motor

oil

to lubri

-

cate the hose reel at points

E,

F,

and

G.

I

nism

to

fail.

1

Improper lubricating will cause the latching mecha-

increasing Spring Tension

(See Fig

6)

Pull

the hose

out

fullv and enoaae the latch. Remove the

dispensingvalveandthe

hosGsGp

(D).

Pullthe hose back

through the hose rollers

(33).

Wrap a loop of hose

onto

the

reel

flange

(13).

~

Check the spring tension; the hose must pull out fully and

retract fully. Wrap more loops, one at a time, around the

reel flange until the spring has the desired tension.

NOTE:

Do

not put

so

many loops onto the reel that

the

spring winds up tightly before the hose is fully

extended. Remove loops to decrease tension.

Route the hose through the hose rollers and rein

-

stall the hose stop and dispensing valve.

hose stop and dispensing valve.

Route the hose through the hose rollers and reinstall the

Replace the Service Hose

(See Fig

6)

to relieve pressure from the service hose. Remove the dis-

Shut

off

the air or fluid supply. Open the dispensing valve

pensing valve and the hose stop. Hold the reel with

GLOVED

hands and let it slide

slowly

through your hands

until the reel stops. When the reel stops the spring tension

the reel.

has been released and the hose can be unwrapped from

NEVER

allow the reel

to

spin freely. Doing

so

causes the hose to spin out of control, which could

cause serious bodily injury if

you.

are hit by the

ALWAYS

wear heavy gloves when unwinding the

spring tension to protect your hands from being cut

on the hose reel.

Fig

6

307

-

694

17

Loading...

Loading...