Swivel

Shut

off

the air or

fluid

supply. Open the dispensing valve

to

relieve pressure fromthe service hose. Pull the hose

Out

fully and engage the latch.

Disassemble the parts as shown in Figures

7

and

8

(depending on your hose reel model). Clean the parts and

inspect them for wear or damage.

Grease the new parts, and fill the cavity of the swivel

assembly (31) with high

-

quality grease. Install the parts as

shown

in

Fig

7

or

8

(depending on your hose reel model).

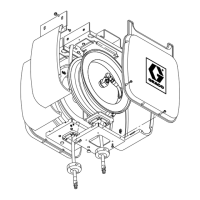

HIGH PRESSURE BARE REEL 218

-

344

32

r

REEL

FLANGE

-u

-

PACKING DETAIL

7

25 26

27

Fig

7

LOW PRESSURE BARE REEL 218

-

345

REEL

FLANGE

I

PACKING DETAIL

Reel

Spring

Shut

off

the air or water supply to the reel. Open the dis

-

pensing valve to relieve pressure from the Sewice hose.

Remove the service hose as described on page 15.

Remove the reel from its mounting base.

Lay the reel on

a flat surface

so

the pedestal

(1)

is on the bottom.

ForBareHoseReel218-344, removetheswivelassembly

(31) and the retaining ring

(1

1).

See

Fig

7.

For

Bare

Hose

Reel

218

-

345, remove the retaining ring

(28),

swivel (31) and retaining ring (1 1). See Fig

8.

Remove the screws (1

8)

and nuts (20) from the reel flanges

(13 and 17). Refer

to

the parts drawings, pages 18 or 20.

WARNING

USE MTREME CAUTION WHEN HANDLING THE

flange, isundergreattensionandcouldbepropelled

SPRING!

The

spring,

which

is

located behlnd the

from

the lower flange

(13)

with enough force to cause

serious bodily

iniory.

To

reduce the risk of serious bodily injury,

use

extreme caution when removing the top reel flange

(17).

Be

sure the reel is laying flat, and then carefully

lifl

up on the flange to expose the spring

(16).

ALWAYS

use

locking pliers

to

compress and hold

several rows of the spring together when removing

and when installing a spring.

See

Fig

9.

Before disposing of the

spring,

carefully attach a

minimum of

two

hose clamps around the keeper and

spring bands as shown in Fig 10.

3 3

Fig

8

Flg

9

-

18

307

-

694

Loading...

Loading...