Spray Techniques

311764D 11

Spray Techniques

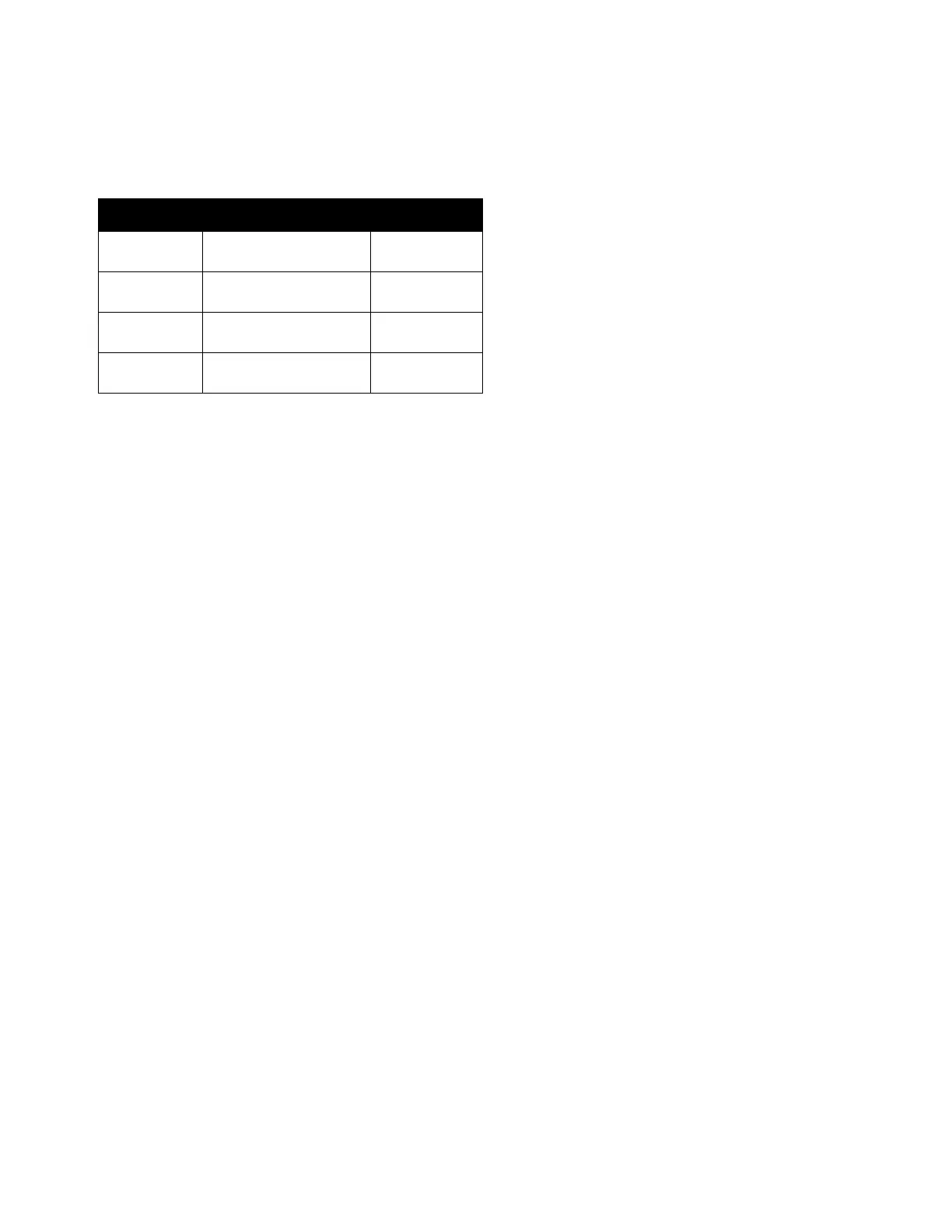

Recommended Nozzle Selection Chart

1

Control air volume with gun air valve.

2

For more material volume try a larger nozzle.

Adjusting the System

Sufficient fluid output (volume and pressure) and good

atomization is a balance of atomozing air, material thick-

ness/material flow and nozzle selection. Achieving the

correct balance for your application requires experimen-

tation to achieve desired results. Keep in mind these

important points when adjusting gun:

• Select proper nozzle for your application. See Noz-

zle Selection Chart. Remember, the larger the noz-

zle, the heavier the pattern.

• Start sprayer with gun air flow valve completely

open. If needed, slowly close gun air flow until you

get a good spray pattern. Use minimum amount of

air at spray gun to achieve proper spray pattern and

to minimize bounce back.

+ Test spray pattern on cardboard. Hold gun 18 to

24 in. (45.7 to 60.9 cm) from surface. Use this

spraying distance for most applications.

• Air and material flow adjustments can be made at

the gun on all units. TX 125 units have a material

flow control knob (G).

+ Opening air valve increases air flow through gun,

which decreases texture material flow through

pump.

+ Closing air valve decreases air flow through gun,

which increases texture material flow through pump.

To Get Less Material

Try one or a combination of these methods:

• Open air valve.

• Turn gun flow adjustment nut to decrease flow,

counter-clockwise.

• Use smaller nozzle.

To Get More Material

Try any one or a combination of these methods:

• Close air valve.

• Turn gun flow adjustment nut to increase flow, clock-

wise.

• Use thinner material mixture.

• Use a larger nozzle.

Preventing Material Surge at Gun Trigger

Pressure will build up in the system when you stop trig-

gering the gun. To prevent material surge at initial gun

triggering:

• Point gun away from surface you are spraying when

you first pull trigger.

• When you first start to spray, hold the gun away from

the surface and gradually work your way closer to it.

• Keep gun moving.

• After you begin spraying, trigger the gun as little as

possible.

For Continuous Spraying

Use trigger lock to hold trigger open and reduce fatigue.

Check Material Consistency Periodically

Check and thin material as needed to maintain proper

consistency. The material may thicken as it sits and slow

down production. Agitate periodically.

Application

Nozzle Size

2

Air Volume

1

Simulated

Acoustic

6 mm, white (fine to medium)

8 mm, gray (coarse)

medium to

high

Orange peel

4 mm, beige,

6 mm, white

medium to

high

Splatter

coat

6 mm, white

8 mm, gray

low to

medium

Knockdown

8 mm, gray

12 mm, black

low

Loading...

Loading...