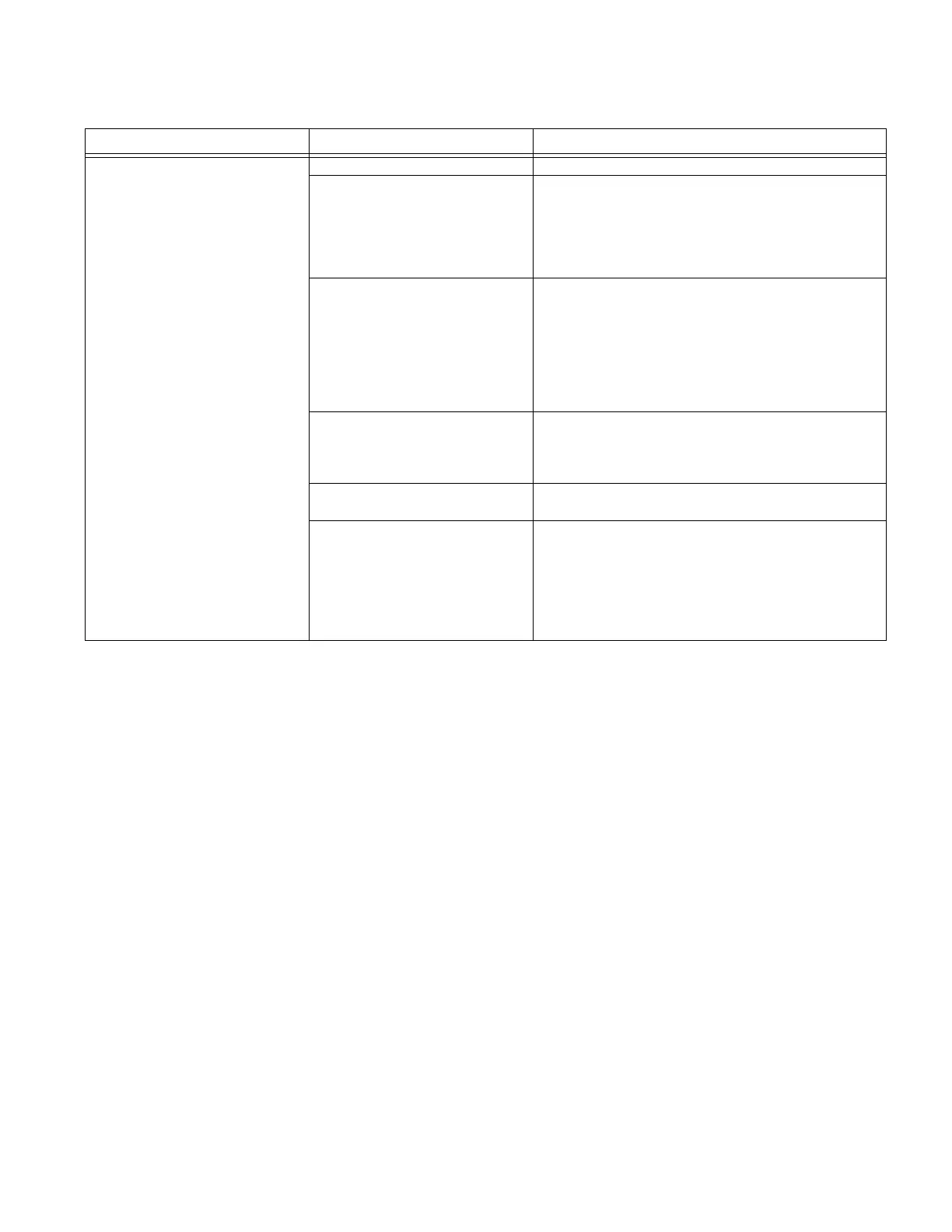

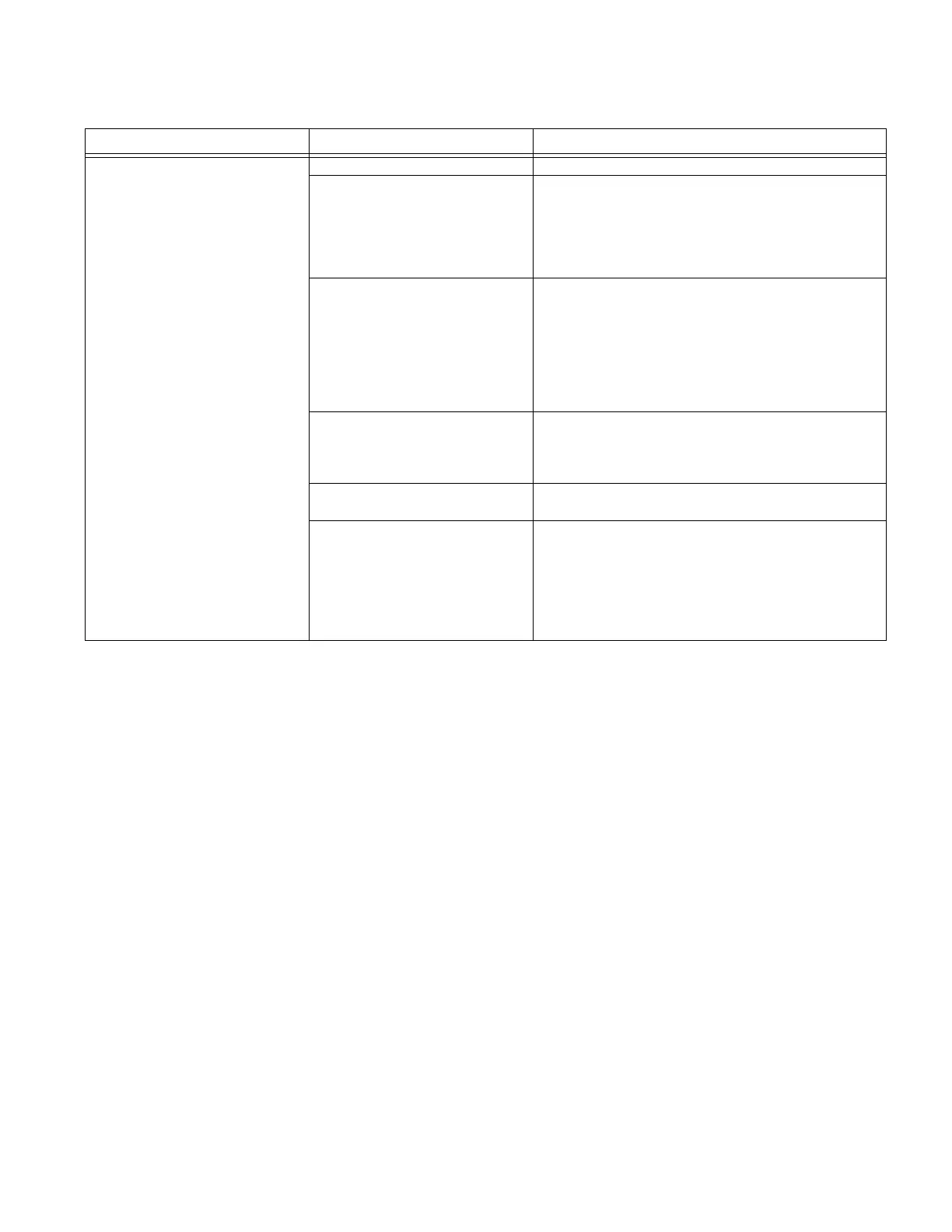

Troubleshooting

3A1222B 13

Basic electrical problems. Motor overheated. Allow motor to cool for 45 minutes. Retry.

Electrical outlet is damaged. Reset building circuit breaker or replace fuse. Try

another outlet.

Check electric supply with volt meter. Meter must read

220 to 240V AC. If voltage is too high, do not plug

sprayer in until outlet is corrected.

Control board leads are improperly

fastened or improperly mated.

Replace any loose terminals. Make sure all leads and

harnesses are firmly connected.

Check pressure control harness connection on front

side of drive housing.

Clean control board terminals. Securely reconnect

leads.

Motor brushes are worn. Check length of BOTH brushes (brushes do not wear

evenly on both sides of the motor). Brush length must

be 0.25 in. (6.4mm). If brushes are worn replace motor

using Motor Kit, page 15.

Motor armature commutator

damaged.

Check for burn spots, gouges and extreme roughness.

Replace motor using Motor Kit, page 15.

Control board damaged.

CAUTION: Do not perform control

board diagnostics until you have

determined the armature is good.

A damaged armature can burn out

a good control board.

See Control Board Diagnostics, page 17. Replace

control board if damaged using Control Board Kit,

page 15.

Problem Cause Solution

Loading...

Loading...