6 309255

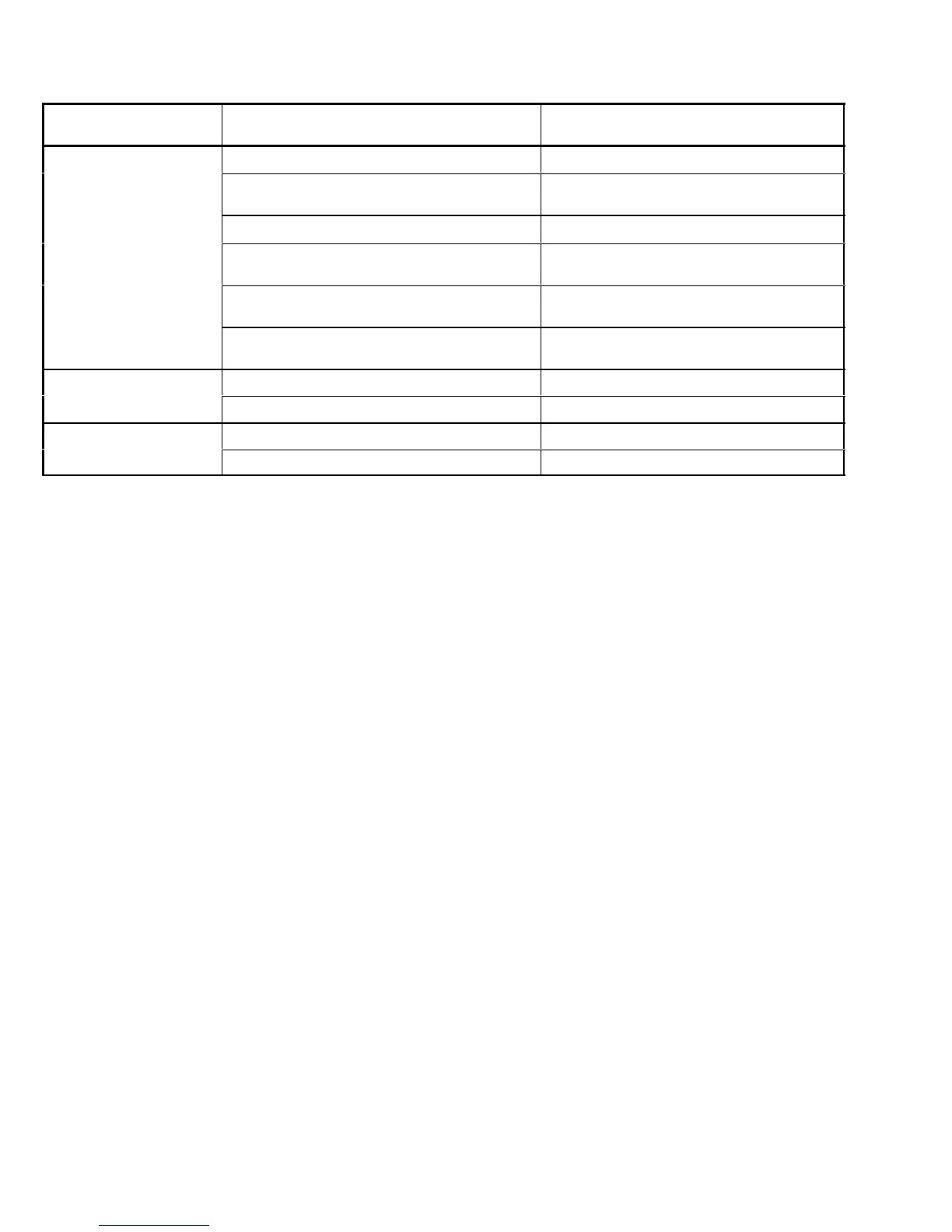

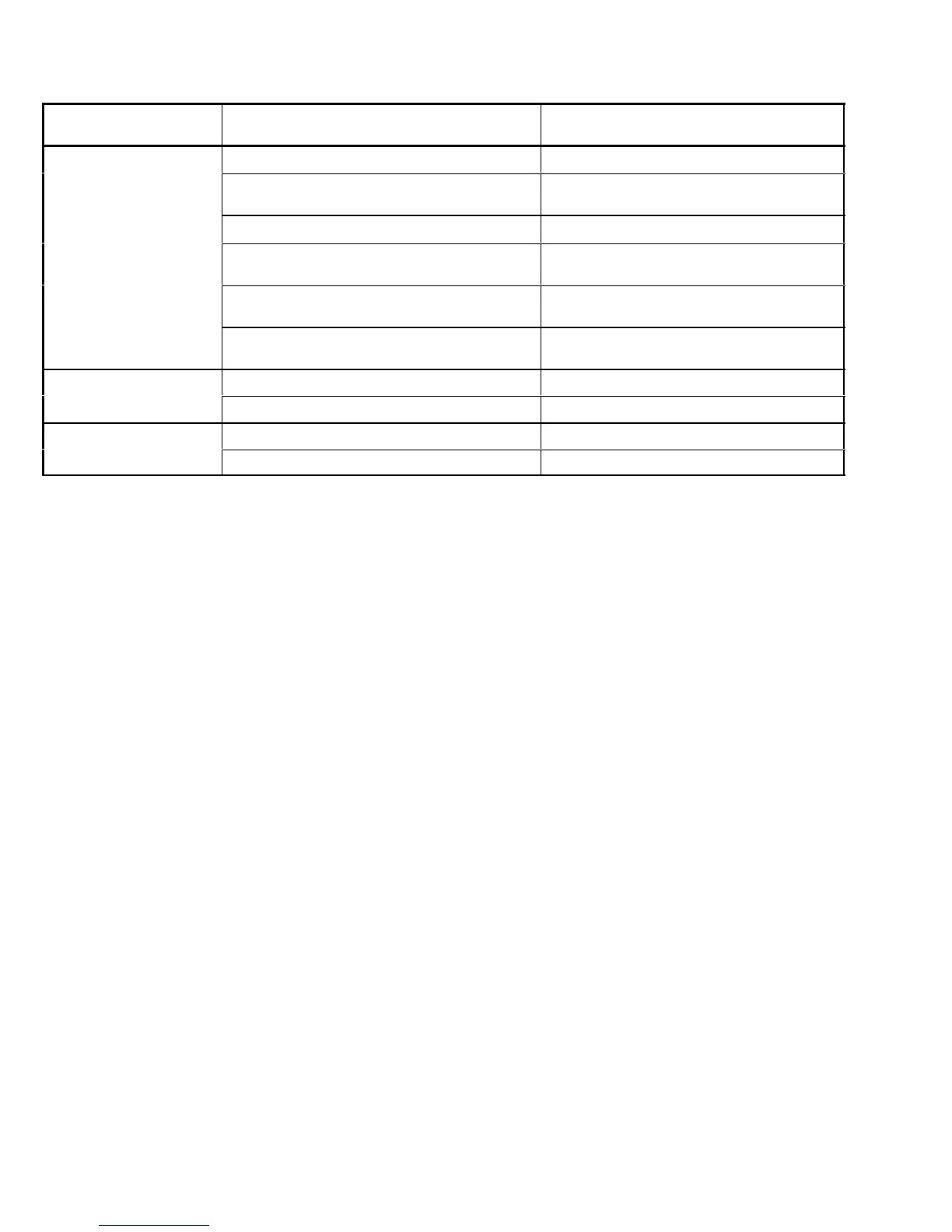

Troubleshooting

PROBLEM

WHAT TO CHECK

If check is OK, go to next check

WHAT TO DO

When check is not OK refer to this column

Motor

1. Connections at control board and brushes 1. Repair any loose connections

2. Brushes worn. Length must be 1/2 in. minimum.

Check both sides.

2. Replace brushes. Page 9.

3. Broken or misaligned brush springs 3. Realign or replace springs

4. Brushes or springs binding in brush holder 4. Clean brush holder and align brush leads for

free movement

5. Check for armature short using an armature

tester (growler) or perform spin test. Page 9.

5. Replace motor

6. Check motor armature commutator for burn

spots or other damage

6. Remove motor and have motor shop resur-

face commutator if possible. Page 20.

Control board or wiring 1. Loose control board wiring 1. Repair any loose connections

2. Damaged control board 2. Replace control board

Control/sensor 1. Potentiometer damaged 1. Replace potentiometer

2. Pressure transducer damaged 2. Replace pressure transducer

Loading...

Loading...