9

Combi 90 Outdoor Module

3 - GENERAL BOILER INFORMATION

General - Grant boilers are compatible with both

copper and plastic pipe. Where plastic pipe is used it

must be of an oxygen barrier type. The first metre of

pipe connected to the boiler must be made in copper.

Sealed systems - Where a sealed heating system is

fitted to the boiler only copper tube may be used.

1 Carefully remove the packaging from the boiler

and lift it off the pallet.

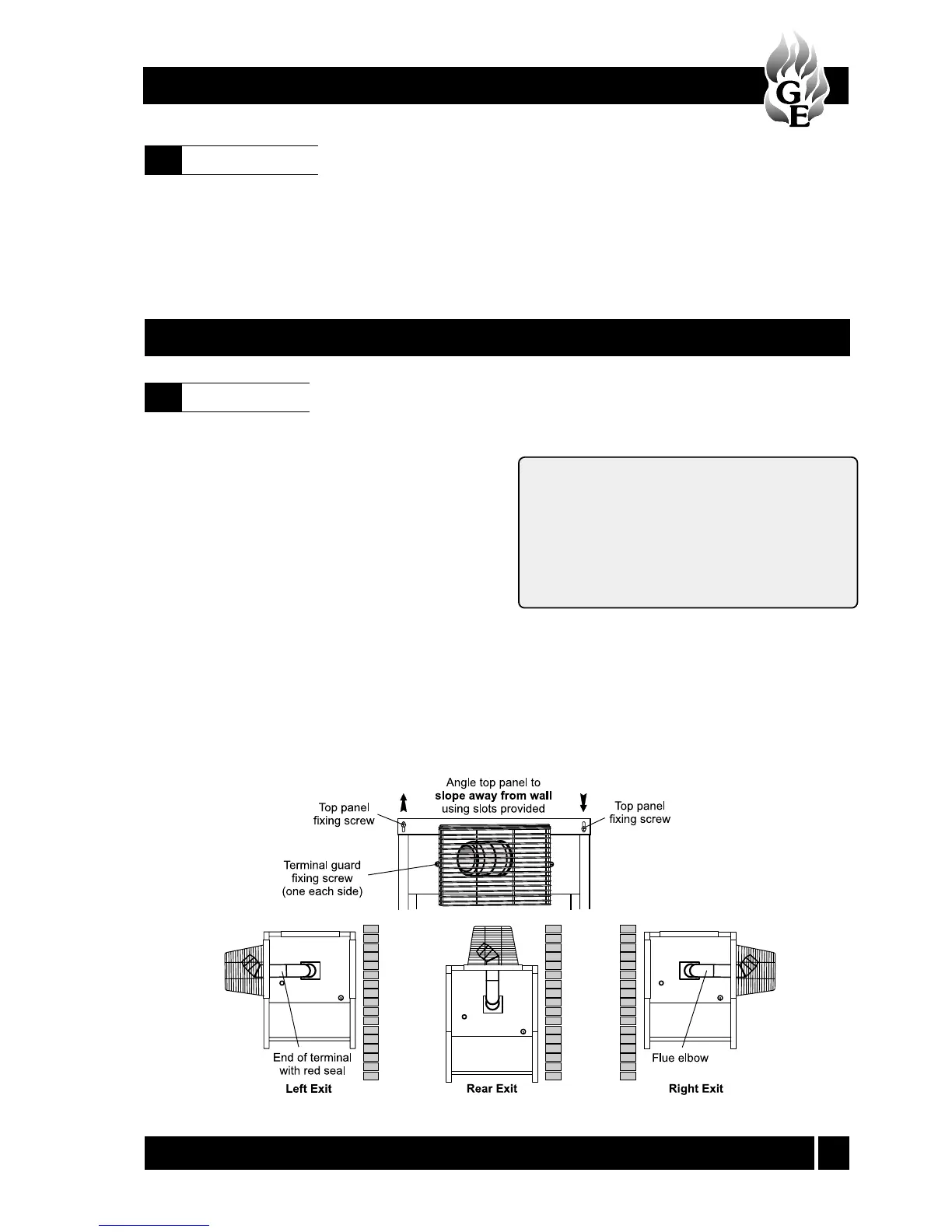

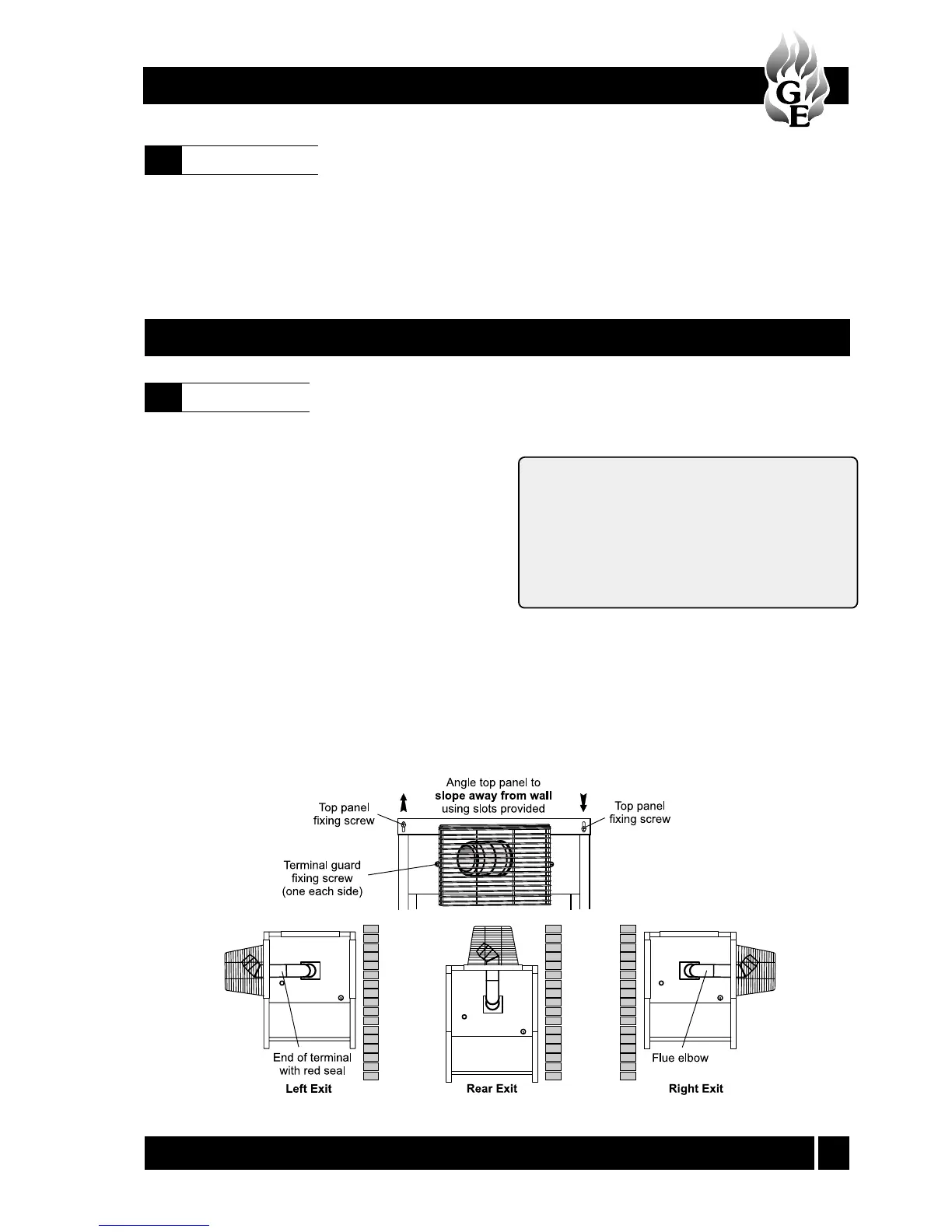

2 The flue terminal guard is supplied loose inside the

packaging.

3 Remove the case top panel (four screws).

4 The flue may exit the casing from the left, right or rear

of the casing. The casing has two removable blanking

panels and a flue exit panel. Fit the panel with the flue

exit hole and seal in the required position.

5 Slacken the wing nuts holding the flue elbow and

rotate the elbow to the required direction for the

flue to exit the casing.

6 Push the end of the flue terminal section with the

red seal through the seal in the casing. The terminal

has been factory lubricated. Take care not to

dislodge or damage the red seals.

Fig. 4

Unpack the boiler

4.1

Pipework materials

3.10

4 - BOILER INSTALLATION

Underfloor systems - Plastic pipe may be used on

underfloor systems where the plastic pipe is fitted after

the thermostatic mixing valve. Copper tube must be

used for the primary pipework between the boiler and

the underfloor mixing/blending valves.

7 Carefully insert the terminal into the flue elbow until

the bend of the terminal contacts the outer casing,

then, pull the terminal forward approximately 25 mm

and rotate the bend so that the outlet is horizontal.

Rear Exit - The flue must discharge away from the

building.

Side Exit - The flue should discharge towards the

rear of the casing to prevent flue gases re-entering

the boiler casing through the air inlet vents on the

casing front door.

The flue terminal must be fitted horizontally to

prevent dripping from the end of the terminal.

8 Tighten the wing nuts holding the flue elbow and fit the

stainless steel flue guard using the two screws provided.

9 The top panel of the casing has been designed so that

it may be fitted to create a slight slope away from the

side positioned against the wall. To tilt the top panel,

loosen the four top panel casing screws, one at each

corner and push down on the side furthest from the

wall. Tighten the screws. See Fig. 4.

Loading...

Loading...