-22-

Model G0708 (Mfd. Since 1/15)

Basic Operation

This section details the correct order of operations

for using the Model G0708.

To use the blast cabinet:

1.

Conduct the daily check listed in Maintenance

on Page 29.

2.

Prepare the workpiece as discussed in Pre-

Use Overview on Page 20.

3.

PUT ON safety goggles and a respirator.

4.

Select and load the blasting media through

one of the doors. Never load media that

contains free silica, as this is a leading cause

of silicosis. Refer to Page 25 for media

types.

Note: Loading just enough media for the job at

hand will help you prevent over-using or having

to screen excess media. Typically use enough

media to cover the metering valve opening by

6" Keep the metering valve adjusted properly

for the type of media blasting being done and

the media being used.

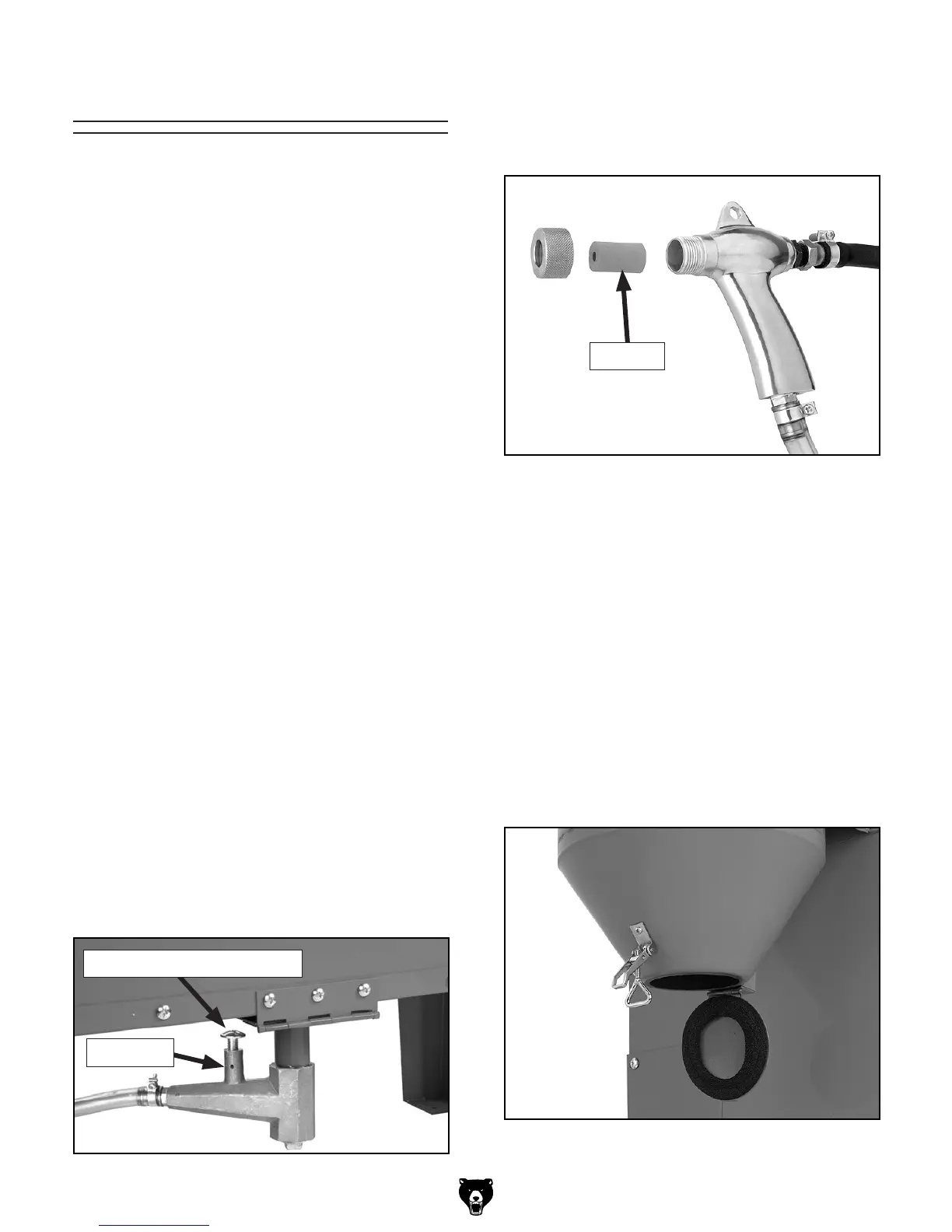

Note: If the metering valve screw (Figure 18)

is turned clockwise and restricts the vents too

much, the gun will pulsate and a low-velocity

rich-media spray will result. If the metering

valve screw is turned counterclockwise too

far, opening the vents too much, the gun will

be noisy and a lean media spray will result.

Under both conditions, low productivity is the

ultimate outcome. Trial-and-error is the best

way to sort out your adjustments for the type

of media and blasting to be done.

5.

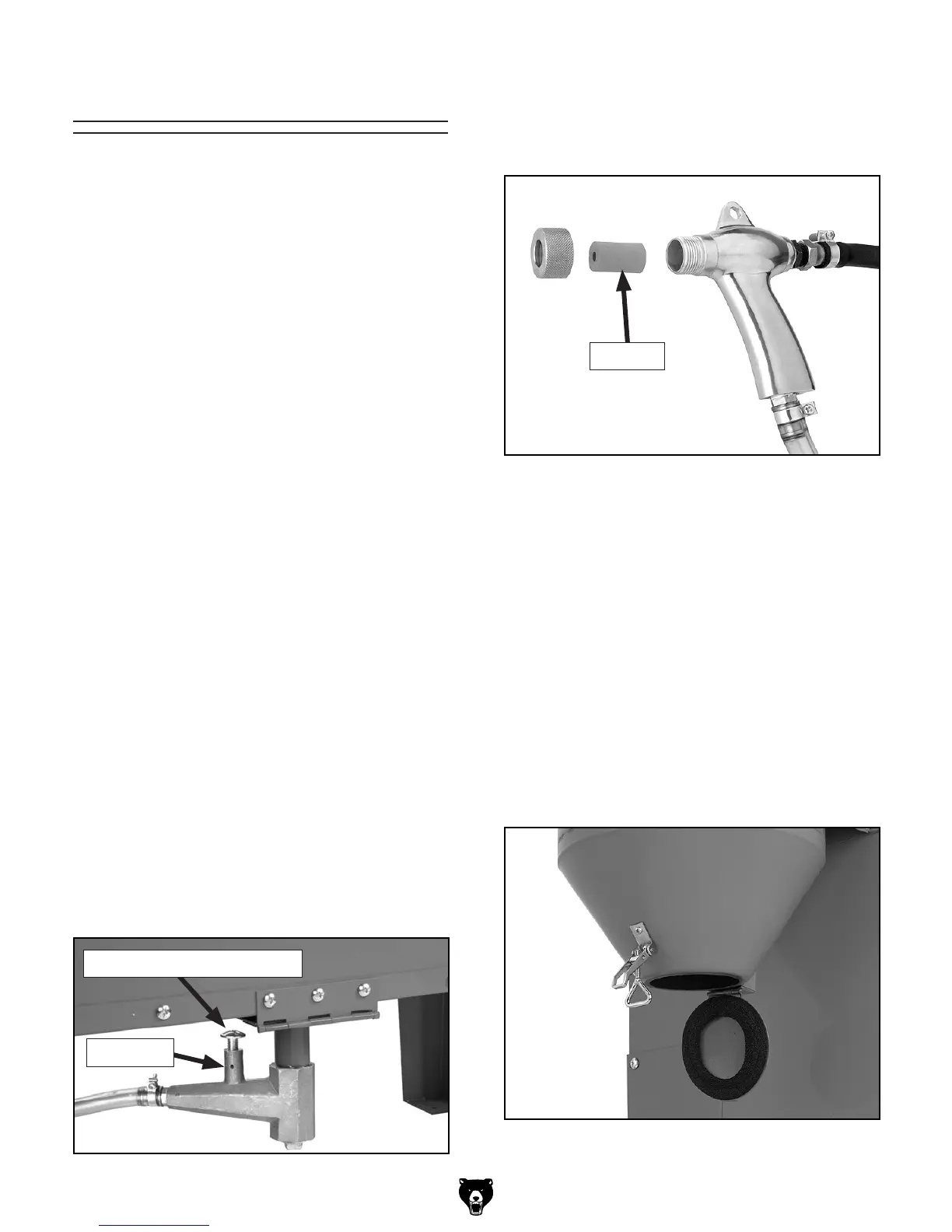

Install the correct tip into the blast gun, in the

order shown (Figure 19). For lower air use

the 6mm tip is used most often. Refer to Page

25 for air pressure and media options.

Figure 18. Metering valve.

Metering Valve Adjustment

Vent Hole

Figure 19. Blast tip installation.

Figure 20. Dust collector dump chute.

Note: It is very important to maintain

concentricity of the tip orifice as it wears. To

do this you must rotate the media blasting tip

1

⁄4-turn every 10 to 12 hours of use. Worn tips

make an inconsistent media spray pattern. As

a result, surfaces can be left with streaking

or spots of tear-out. Replace any tip that has

worn

1

⁄16" in diameter larger than its original

size.

6.

Empty the dust collector canister periodically

during long blasting operations and after every

use. Every five hours of blasting operations,

clean the canister filter using compressed air

(Figure 20).

Blast Tip

Loading...

Loading...