29 5105862_-_HI

8. FAULT ISOLATION CONTINUED

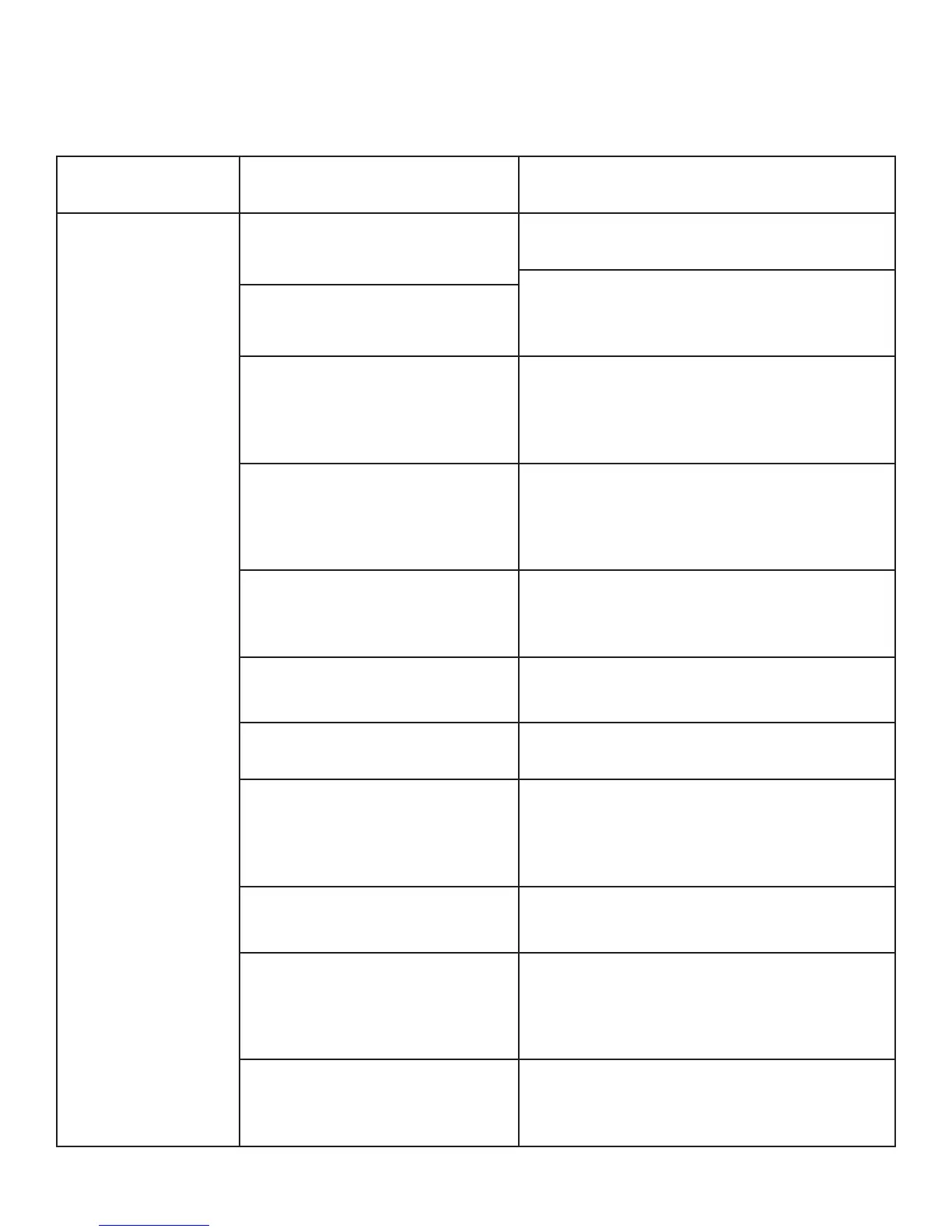

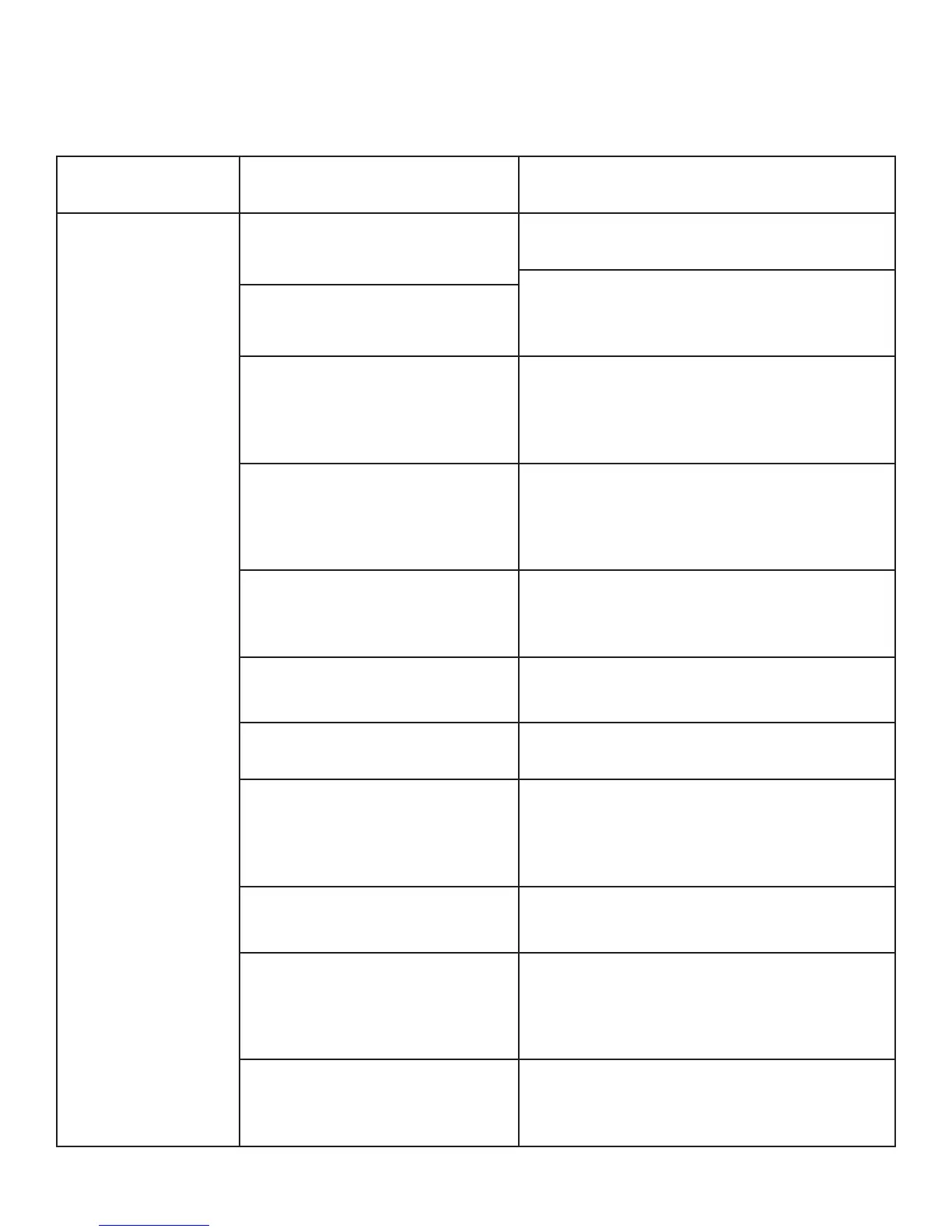

8.3 SPRAYING SYSTEM OPERATES INCORRECTLY

FAILURE MODE CAUSE OF PROBLEM CORRECTIVE ACTION

Spraying pattern is

uneven or spraying

system does not op-

erate.

The spray nozzle tips are out of

position.

Rotate the spray nozzle tips so that the tip ori-

ce is directed straight in front of the machine.

Verify that the lower nozzle (trim nozzle) is posi-

tioned approximately 30 degrees and the upper

nozzle (broadcast nozzle) is positioned straight

up and down.

The spray nozzles are out of

position.

The spray valve is not in the cor-

rect position.

Verify that the spray valve is in the horizontal

position when spraying. The valve lever can be

moved either forward or backward to the hori-

zontal position to operate. The valve is “OFF” in

the vertical position.

The pressure relief valve is set

incorrectly.

Verify that the pressure gauge reads approxi-

mately 25 psi at full engine speed. Adjust the

pressure relief knob in or out to obtain this

pressure. Tighten the locking nut against the

pressure relief knob.

The strainer or tip is clogged. Remove the spray nozzle tip and inspect the tip

orice and the strainer to make sure they are

not clogged. Clean or replace these compo-

nents as necessary.

The lter is clogged. Remove the sediment bowl from the lter

housing and inspect the lter screen. Clean or

replace the screen as necessary.

The spray pattern knob is incor-

rectly set.

Move the spray pattern knob all the way to side

of the desired pattern setting.

The spray tank volume is low. Rell the spray tank. Note that in very rough

or hilly conditions, the liquid in the spray tank

may slosh around and the tank discharge tube

may starve when the tank level is low. This can

cause poor spraying performance.

The engine speed is too low. Operate the machine at full engine speed. The

spray system is designed to operate most ef-

ciently at full engine speed.

The pump is worn or damaged. Loosen the suction tting on the pump to verify

that there is liquid ow to the pump. Tighten the

suction tting and loosen the discharge tting

to verify that the pump is operating correctly. If

there is no ow, replace the pump.

The pump input shaft is not spin-

ning.

Verify that all of the belts are in good condition

and are tensioned properly. Verify that the pump

pulley is securely fastened to the pump shaft

with a setscrew.

Loading...

Loading...