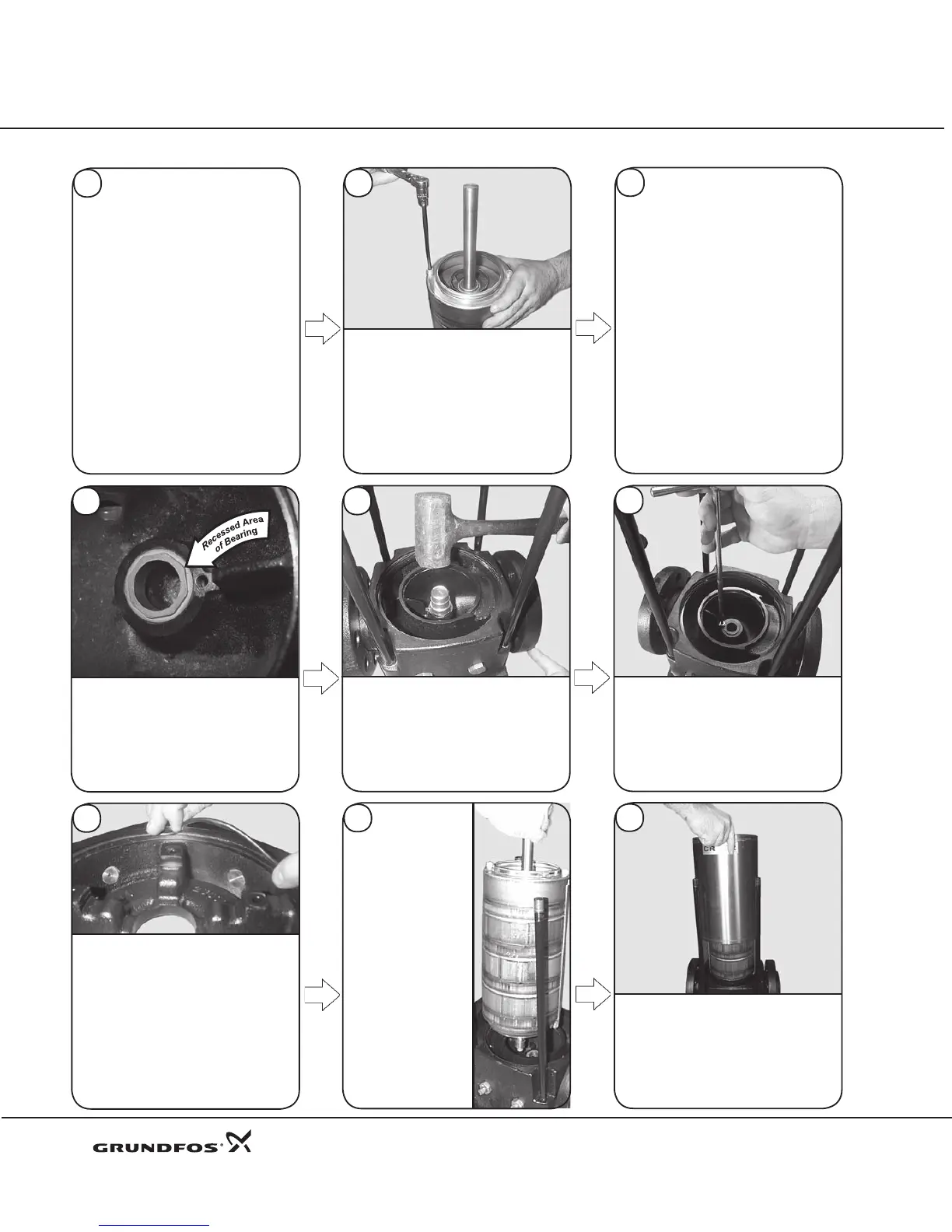

Refer to the diagrams on pages

22-26 for the appropriate staging

sequence for your particular

model pump. Once the last

chamber has been installed,

continue with step 9.

Hook the Chamber Straps (Pos. 26a)

through the Base Interface (Pos. 44).

Position top end of straps into relieved

area of the Top Chamber (Pos. 3).

Place the Washer (Pos. 26c) and Allen

Screws (Pos. 26b) loosely threaded

into the straps. Allen screws must

be pre-lubricated with Gardolube.

Torque evenly to 11 ft.-lbs./15 Nm.

Remove the holding pin from the

assembly/dismantling fixture.

Lift the STACK® (Pos. 80) out of

the xture. Lay the stack on a at

surface and check the rotation and

end play*. Movement should be

free and without binding.

* End play is shaft travel (up and down)

through the chambers.

10

8

9

14

Reassembly Procedures CR, CRN 32•45•64•90

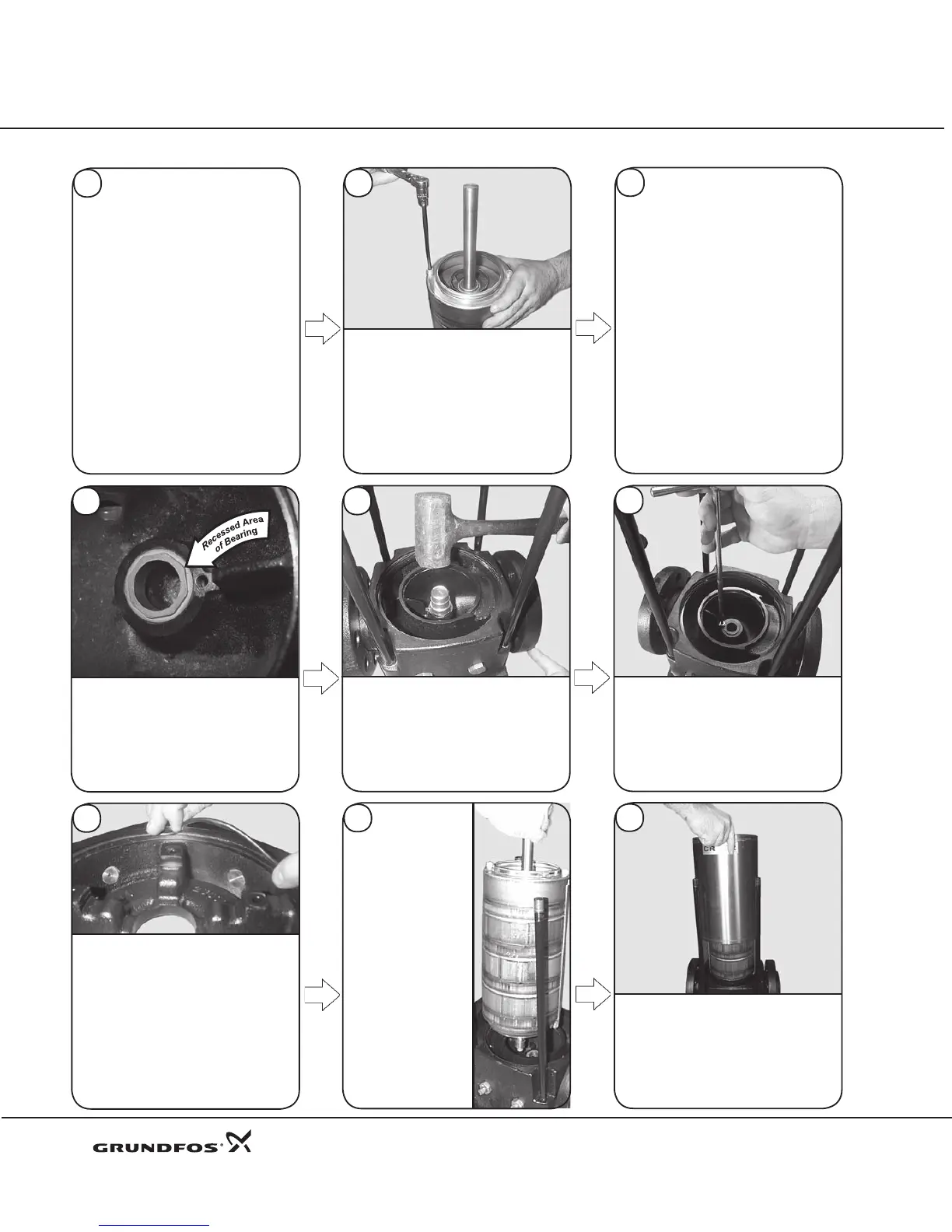

Place the Washer (Pos. 32) and

the 5 mm Allen Screw (Pos. 31)

into the suction/discharge base.

Torque the screw to 6ft.-lbs/8Nm.

To install the Bottom Bearing (Pos.

6g) into the Suction/Discharge Base

(Pos. 6), place the bearing into the

hole provided in the base. Ensure

the recessed area of the bearing

is located where the hole for the

allen screw is machined in the base.

Use the bearing punch (00SV0015

or 00SV0212) and a rubber mallet

to drive the bearing into place.

13

11

12

16

15

Place the STACK®

into the suction/

discharge base. Rotate

the straps so they center

between the Staybolts

(Pos. 26) or line up

with the suction and

discharge ports of the

base. Recheck the shaft

end play (shaft travel up

and down) and the shaft

rotation. Movement

should be free without

binding. If binding

occurs stop, remove

the stack and check

clearance between the

bottom shaft bearing,

be a ri n g cl a mpi ng

washer and the bearing

in the base.

Place Sleeve (Pos. 55) into the

suction/discharge base. Press

sleeve firmly into the base.

Place the Sleeve O-ring of EPDM or

FKM (Pos. 37) into the recessed groove

in the Pump Head (Pos. 2, 2b, & 2c)

and the suction/discharge base for

standard units. Specialty O-rings in

FXM or FFKM (Pos. 37a) are used in

the lower hot section of the pump in

Cool Top equipped pumps. Lubricate

the O-rings with Rocol (00RM2924)

or Dow Corning 111. Never use oil or

grease as this will attack the O-rings.

14

Loading...

Loading...