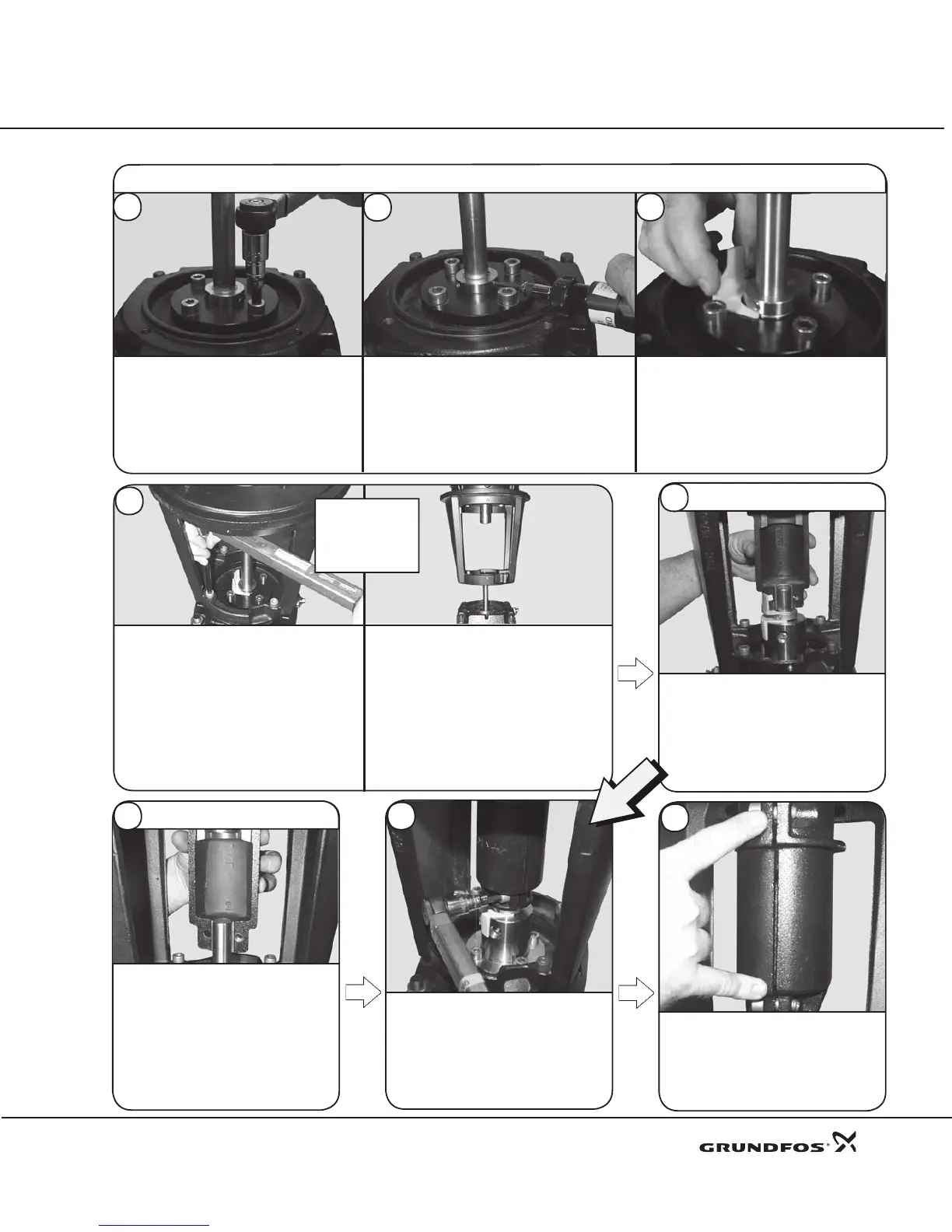

The motor, motor stool, and/or bearing ange

will be assembled as a complete unit. Place

the entire assembly onto the pump head.

Lubricate the threads on the 8 mm hex socket

Retaining Screws (Pos. 28) with Gardolube or

Thread-Eze. Install and diagonally torque to

46ft.-lbs./62Nm. If the motor was removed

during disassembly, reattach the motor.

Lubricate the threads of the Motor Bolts (Pos.

28a) and then tighten the bolts diagonally to:

30 ft.- lbs./41 Nm for 1/2" x 13 UNC, 3-40 HP

59 ft.- lbs./80 Nm for 5/8" x 11 UNC, 50-60 HP

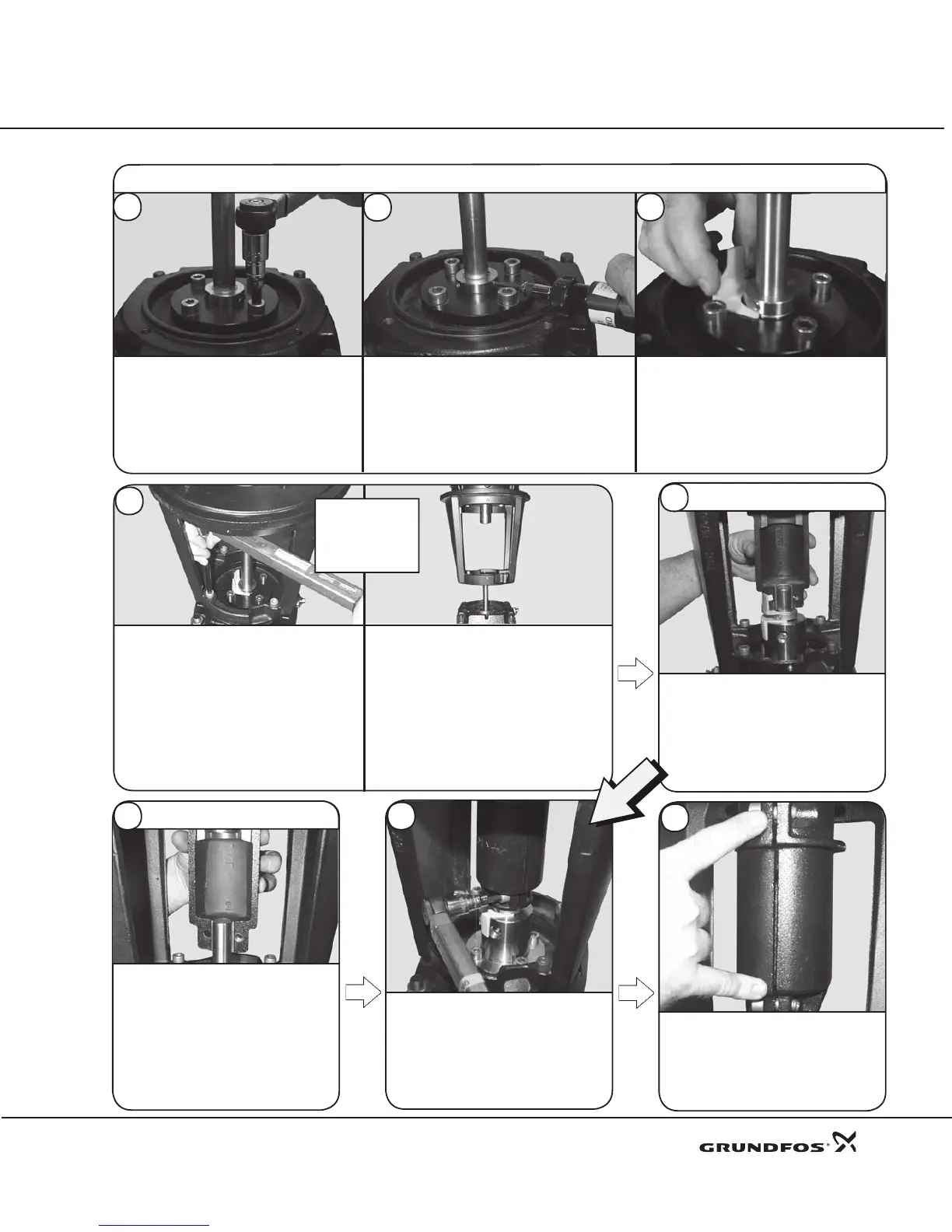

To install the Coupling Halves

(Pos. 10a), position the coupling

half relief area flushed with the

top of the shaft as shown in the

diagram. Lubricate the threads on

the 8 mm hex socket Coupling Screws

(Pos. 9) with Gardolube or Thread-Eze.

Loosely thread the screws in place.

Reassembly Procedures CR, CRN 32•45•64•90

Push the shaft downward (for Back-to-

Back units, continue downward pressure

as the inboard seal spring tension may lift

the shaft). Evenly tighten, then torque the

three 3 mm set screws to 6 ft.-lbs./8Nm.

Place a second adjusting fork

on top of the seal collar. Install

the Coupling Halves (Pos. 10a).

Lubricate the threads on the

8 mm hex socket Coupling Screws

(Pos. 9) with Gardolube or Thread-Eze.

Loosely thread the screws in place.

Torque the 8 mm hex socket coupling

screws to 63 ft.-lbs./85Nm. This step

is the same for all pump types (in the

photo a tandem seal version is shown).

61

Li ft th e sh aft and i nsert t he

adjusting fork under the seal collar.

Lo we r a nd s eat t h e Ret a in er

(Pos. 58). Lubricate the threads of

the 8 mm hex socket Retaining

Screws (Pos. 58a) with Gardolube

or Thread-Eze. Install and diagonally

torque the screws to 46ft.-lbs./62Nm.

62

Make sure the gaps on both sides of

the coupling are even. Applies to all

pump types.

Attach the motor and motor stool separately

to the pump head. Lubricate the threads

on the 8 mm hex socket Retaining Screws

(Pos. 28) with Gardolube or Thread-

Eze. Install and diagonally torque to

46ft.-lbs./62Nm. Place the motor

ont o the mo tor st ool , lub ric ate

the threa ds of the M otor B o lts

(Pos. 28a) and tighten the bolts diagonally to

30 ft.-lbs./41Nm.

58

Placement of the

Motor Stool (Pos. 1a)

differs depending on

model size.

15 HP

and up

3 - 10 HP

and Up

Tandem Seal Only

59

Standard, Cool Top®, &

Back-to-Back Seal Units

60

21

Standard, Cool Top®, & Back-to-Back Seal Units

56

57

55

ALL PUMP TYPES

Loading...

Loading...