English (GB)

13

4.1.4 Assembling the chamber stack

For chamber types, see section 7.4 Order of assembly for

chambers and impellers.

1. Install the inlet part (44) over the pump shaft (51) which is

placed in service tool H1 or H2.

2. Fit the impeller (49 or 49a) which was removed as the last one

during dismantling.

3. Fit a split-cone (49b) in the impeller (49 or 49a).

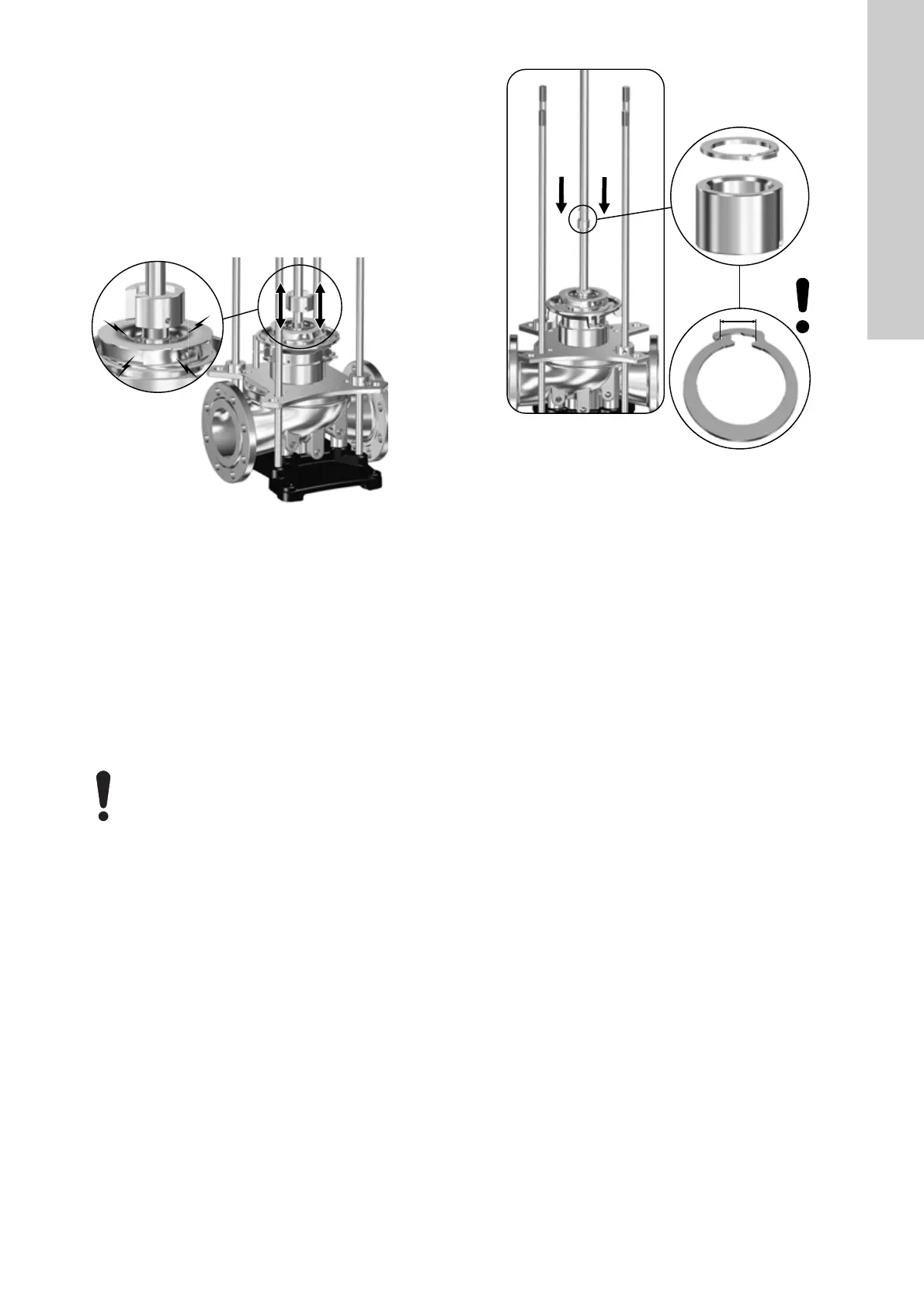

4. Turn service tool C around and knock it against the split-cone

(49b) to fixate the impeller (49 or 49a) to the pump shaft (51).

See fig. 27.

Fig. 27 Fixating the impeller (49 or 49a) to the pump shaft (51)

with service tool C

5. Fit a split-cone nut (48) to the impeller.

6. Hold the impeller (49 or 49a) with a hook spanner. Tighten the

split-cone nut (48) using the service tools C, O and P. See

section 7.1 Torques.

7. Lubricate and fit the bearing (47a). See section

7.2 Lubricants.

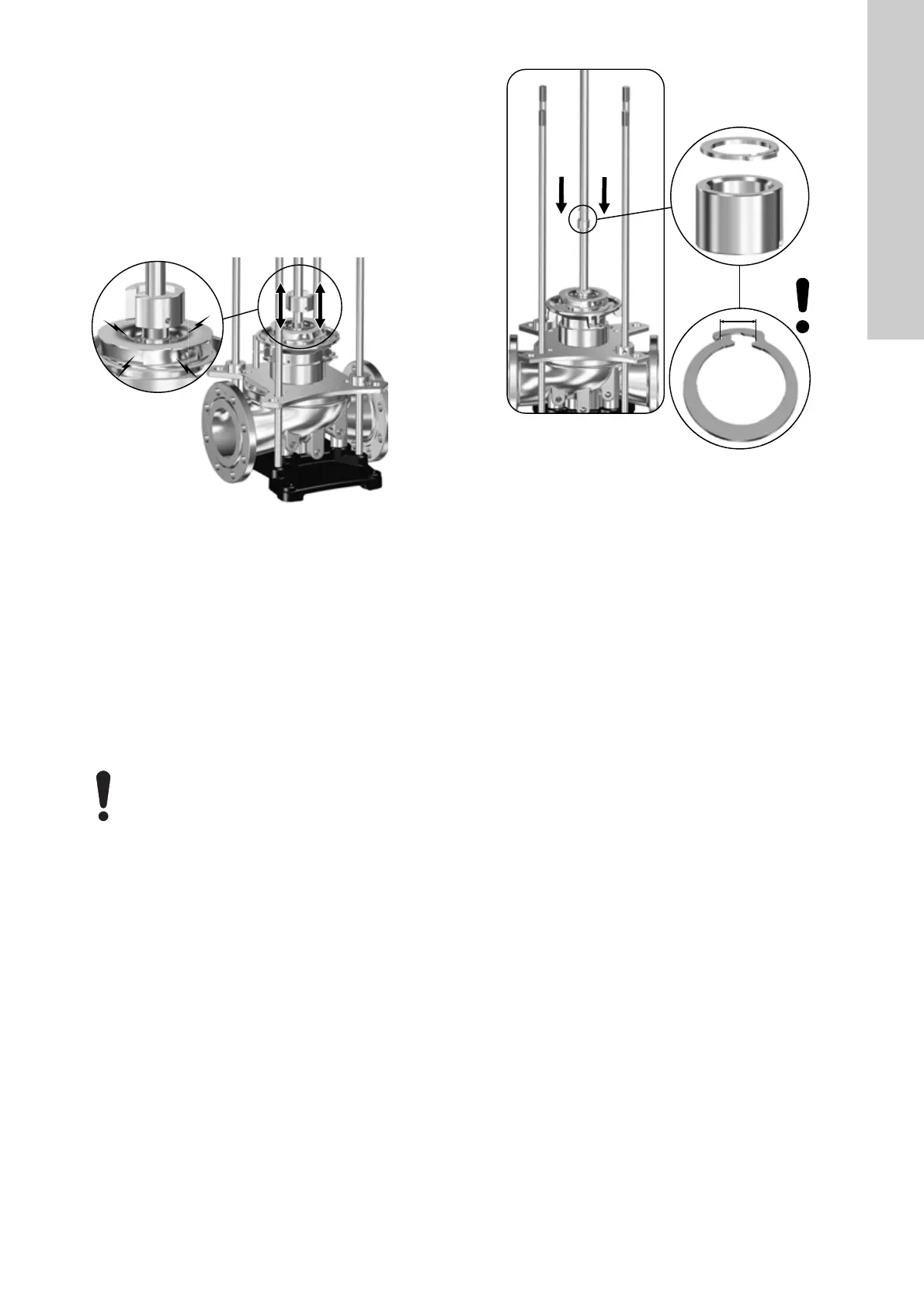

8. For pumps with ∅28 or ∅38 pump shaft: Note that for

pumps with ∅28 or ∅38 pump shaft, you must also fit the lock

ring (47g). See fig. 28.

Make sure that the lock ring (47g) tightens firmly around the

pump shaft and holds the bearing (47a) fixed on the pump

shaft.

Fig. 28 Maximum permissible opening of lock ring (47g)

9. Fit the bottom chamber with bearing (4a), and press it home

on the inlet part (44).

10. Continue installing the remaining chambers (4), split-cone

nuts (48), split cones (49b), impellers (49 or 49a) and

bearings (47a).

11. Fit the outlet part (3b) on the top chamber.

12. Fit the strap (26a), washers (26c) and screws (26b). Lubricate

and tighten the screws. See sections 7.1 Torques and

7.2 Lubricants.

13. Carefully lift the chamber stack with approved lifting

equipment.

14. Follow the assembly instructions described in section

3.2.3 Assembly.

TM07 1896 2218

Do not open the lock ring (47g) further than the

restriction of the integrated locking mechanism. See

fig. 28.

TM07 2073 2618

Loading...

Loading...