6

Setting and executing additional control functions

• Remote on/off (byte 2/bit 0)

– Switches the pump on and off. For switching on, the pump

must not have been manually stopped or switched off via

external remote on/off. External remote off and switching off

via PROFIBUS switch the pump off independently of each

other.

• Slow mode (byte 2/bit 1)

– Slow-mode operation is switched on and off.

• Continuous operation for deaeration and suction (byte 2/bit 2)

• Deletion (resetting) of the total capacity dosed (byte 2/bit 3)

– The display of the total capacity dosed (since the pump was

last reset) is reset to zero.

• Error resetting (byte 2/bit 4)

– Resetting of an error that has occurred and restarting of the

pump if it was set to "Start" locally.

• Dosing controller (byte 2/bit 5)

– An installed Flow Monitor can be switched on and off.

6.3.2 Messages returned from the pump

Data flow from the pump to the PROFIBUS master

8 bytes are available for returning messages from the pump:

The following data is sent from the pump to the PROFIBUS

master via PROFIBUS-DP:

• Actual value: volume flow (ml/h) / chamber pressure (mbar)

(bytes 1, 2)

– The set setpoint is determined if "Transfer of actual value" is

set to "Volume flow" (DDI 209 in ml/h, DDI 222 in cl/h).

The chamber pressure in mbar is transferred when

"Pressure value" is set and "Pressure control" is activated.

• Display of the total capacity dosed (bytes 3, 4)

– Display of the total capacity dosed in dl (decilitres) since the

value was last reset.

• Error messages (bytes 5, 6/bits 15-0)

– dosing controller

– diaphragm leakage detection

– external pre-empty signal

– empty signal

– Hall sensor (for motor monitoring)

– PROFIBUS communication

– current control – for operating mode "manual" 4-20 mA.

An error message is sent if the current input is < 2 mA.

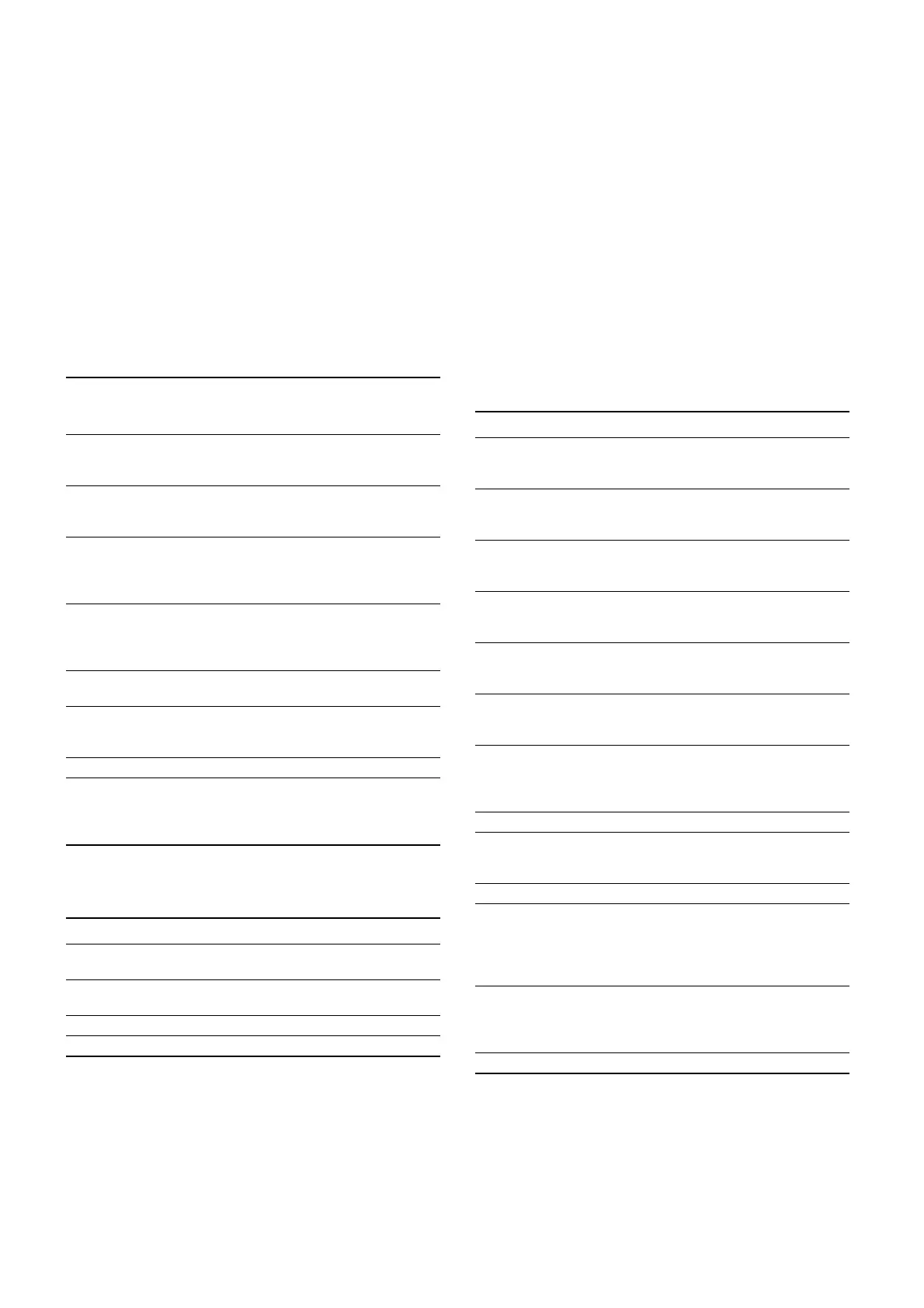

Bit

Byte 2:

Control functions for

DDI 209

Byte 2:

Control functions for

DDI 222

0

Remote on/off

0 = off

1 = on

Remote on/off

0 = off

1 = on

1

Slow mode

0 = off

1 = on

Slow mode 1

0 = off

1 = on

2

Continuous operation

(deaeration mode)

0 = off

1 = on

Continuous operation

(deaeration mode)

0 = off

1 = on

3

Deletion (resetting) of the

total capacity dosed

0 -> 1 = Resets the total

capacity dosed

Deletion (resetting) of the

total capacity dosed

0 -> 1 = Resets the total

capacity dosed

4

Error resetting 0 -> 1 =

Resets the error

Error resetting 0 -> 1 =

Resets the error

5

Flow

0 = off

1 = on

Flow

0 = off

1 = on

6 Reserve Slow mode 2

7

Pressure monitoring, only

with Flow Monitor option

0 = on

1 = off

Pressure monitoring

0 = on

1 = off

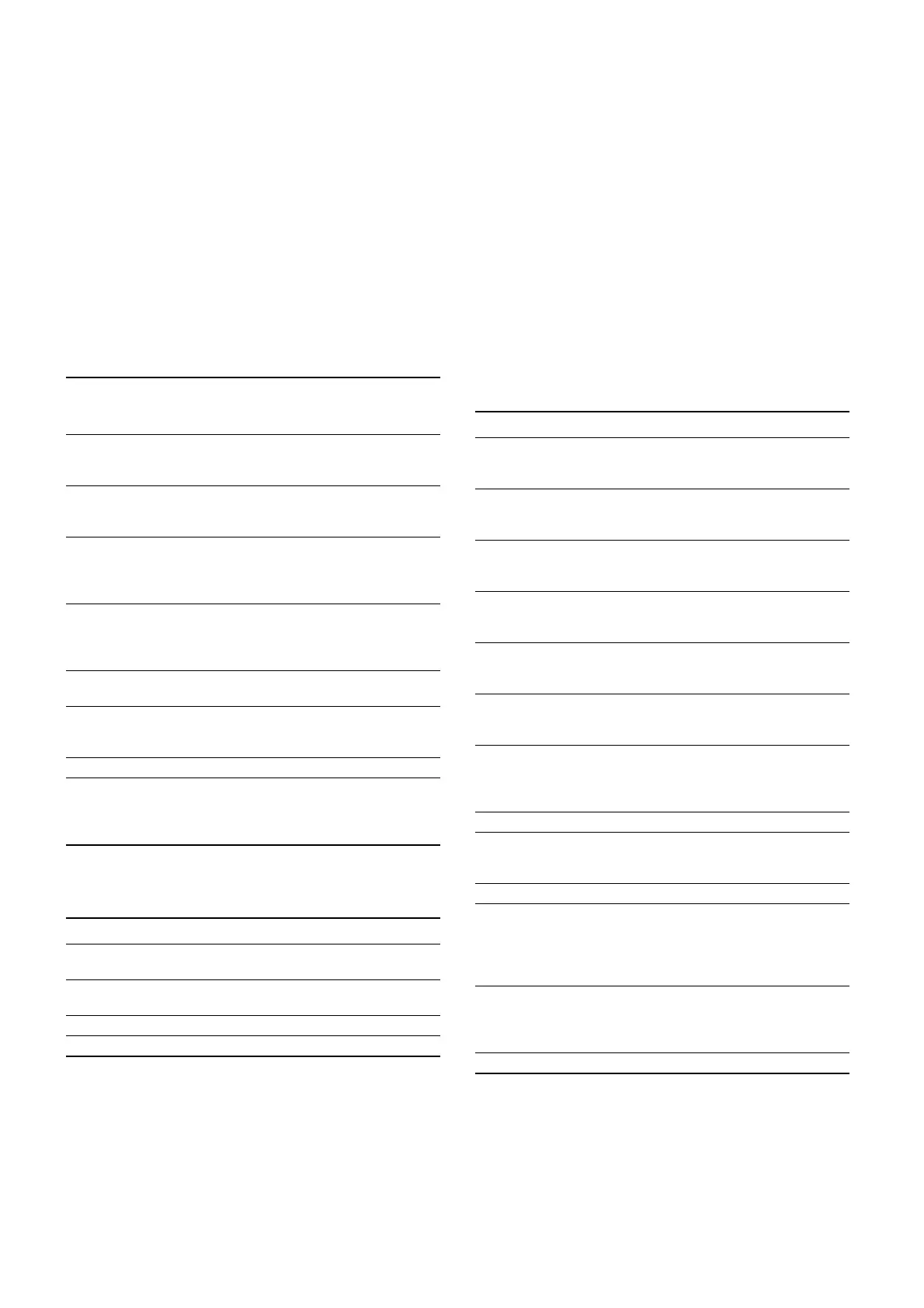

Byte Data type Data length [byte]

1, 2

Unsigned 16

Highbyte, Lowbyte

2

3, 4

Unsigned 16

Highbyte, Lowbyte

2

5, 6 Unsigned 16 2

7, 8 Byte 2

Bit Bytes 5, 6: Error messages

0

Dosing controller

0 = no error

1 = error

1

Diaphragm leakage detection (MLS)

0 = no error

1 = error

2

Pre-empty signal

0 = no error

1 = error

3

Empty signal

0 = no error

1 = error

4

Hall sensor (for motor monitoring)

0 = no error

1 = error

5

PROFIBUS communication (inverse)

0 = error

1 = no error

6

Current control

(< 2 mA in operating mode 4-20 mA)

0 = no error

1 = error

7, 8 Reserve

9

Internal pre-empty signal

0 = no error

1 = error

10 Reserve

11

Only for DDI 209 with Flow Monitor and DDI 222:

If the pressure is exceeded 5 times (starting can be

initiated after 10 minutes)

0 = no error

1 = error

12

Only for DDI 209 with Flow Monitor and DDI 222:

If the pressure is exceeded 1-5 times in succession

0 = no error

1 = error

13-15 Reserve

Loading...

Loading...