English (GB)

12

13. Fault finding

The table below covers the most frequent faults.

Contact Grundfos if the table does not cover the specific fault.

14. Service

All repairs must be carried out in accordance with IEC 60079-19.

Observe the provisions of EN 50110-1 until all maintenance work

has been completed, and the motor has been assembled.

14.1 Motor bearings

Take care when replacing the motor bearings.

14.2 Service documentation

Service documentation is available on www.grundfos.com >

WebCAPS > Service.

If you have any questions, please contact the nearest Grundfos

company.

15. Disposal

This product or parts of it must be disposed of in an

environmentally sound way:

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest Grundfos company

or service workshop.

Subject to alterations.

Warning

Before starting fault finding, switch off the power

supply. Make sure that the power supply cannot

be accidentally switched on.

Motor service and fault finding must be carried

out by qualified personnel.

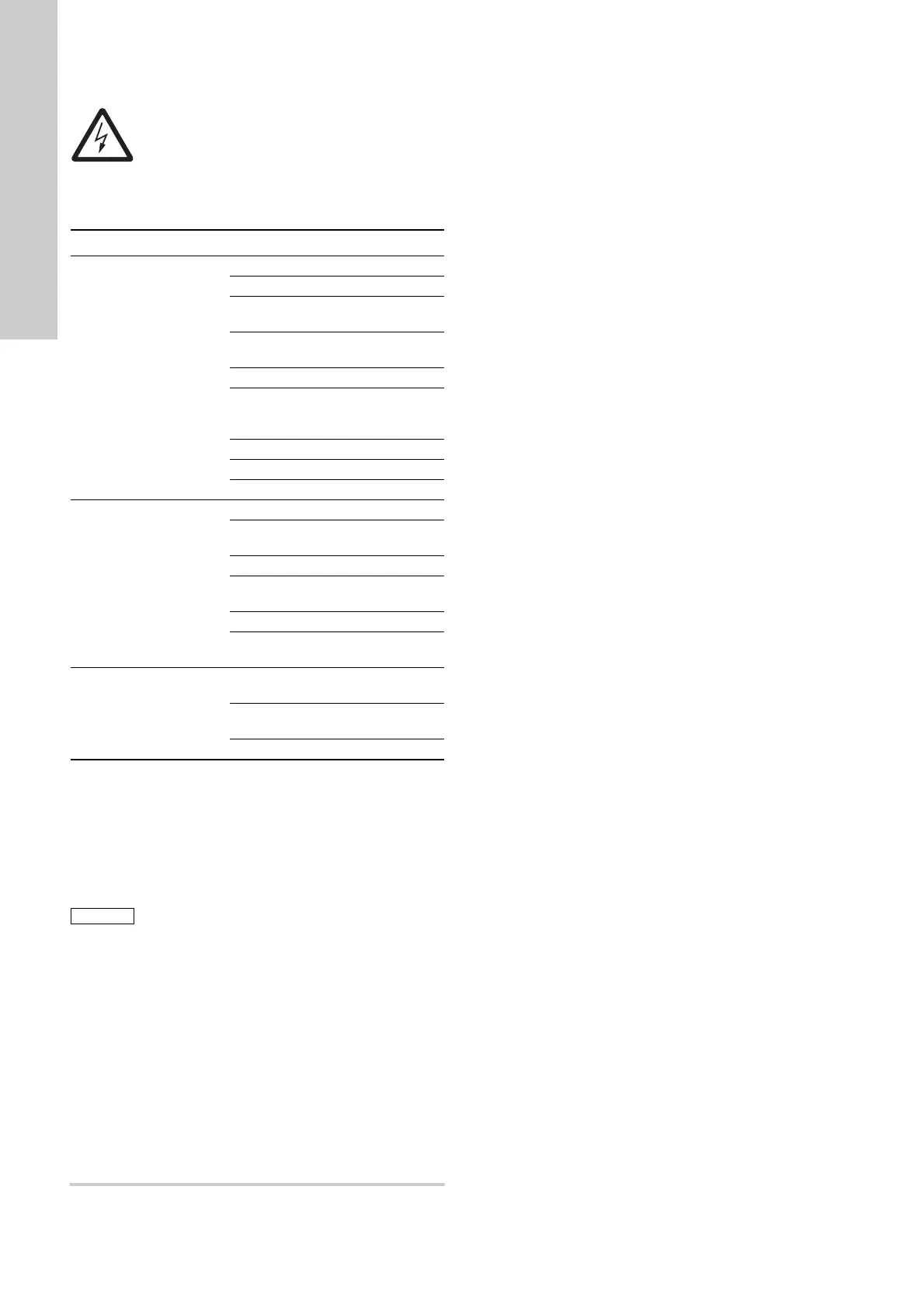

Fault Cause

1. Motor does not start. a) Power supply disconnected.

b) Fuses blown.

c) Automatic circuit breakers cut

out.

d) Motor-protective circuit breaker

tripped.

e) Thermal protection tripped.

f) Contacts of motor-protective

circuit breaker or magnet coil

defective.

g) Control circuit defective.

h) Blocked rotor.

i) Motor defective.

2. Motor-protective

circuit breaker trips

immediately when

supply is switched on.

a) A fuse blown.

b) Contacts of motor-protective

circuit breaker defective.

c) Blocked rotor.

d) Cable connection loose or

faulty.

e) Motor winding defective.

f) Motor-protective circuit breaker

setting is too low.

3. Motor-protective

circuit breaker trips

occasionally.

a) Motor-protective circuit breaker

setting is too low.

b) Mains voltage periodically too

low.

c) Voltage asymmetry

Do not expose the bearings to impacts or shocks.

Loading...

Loading...