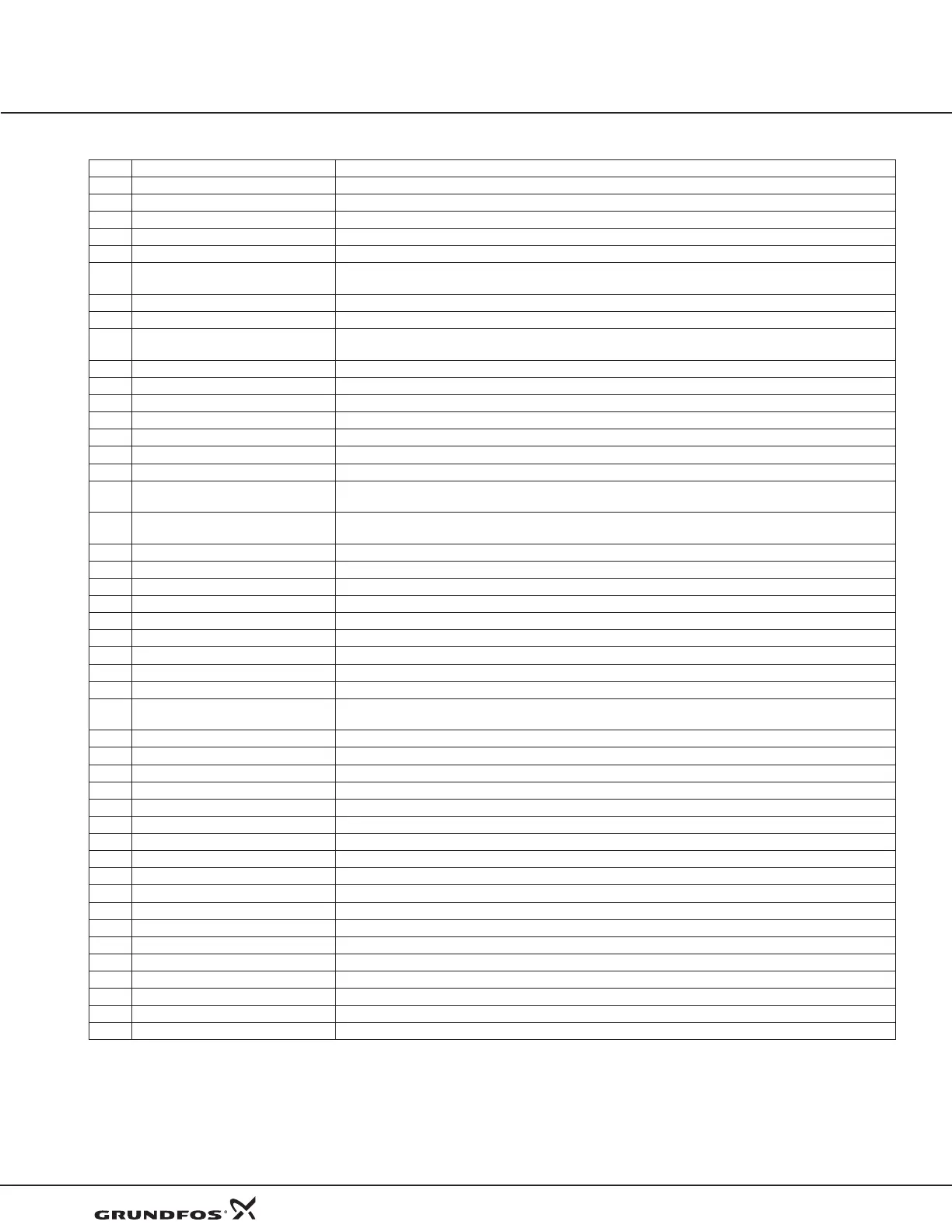

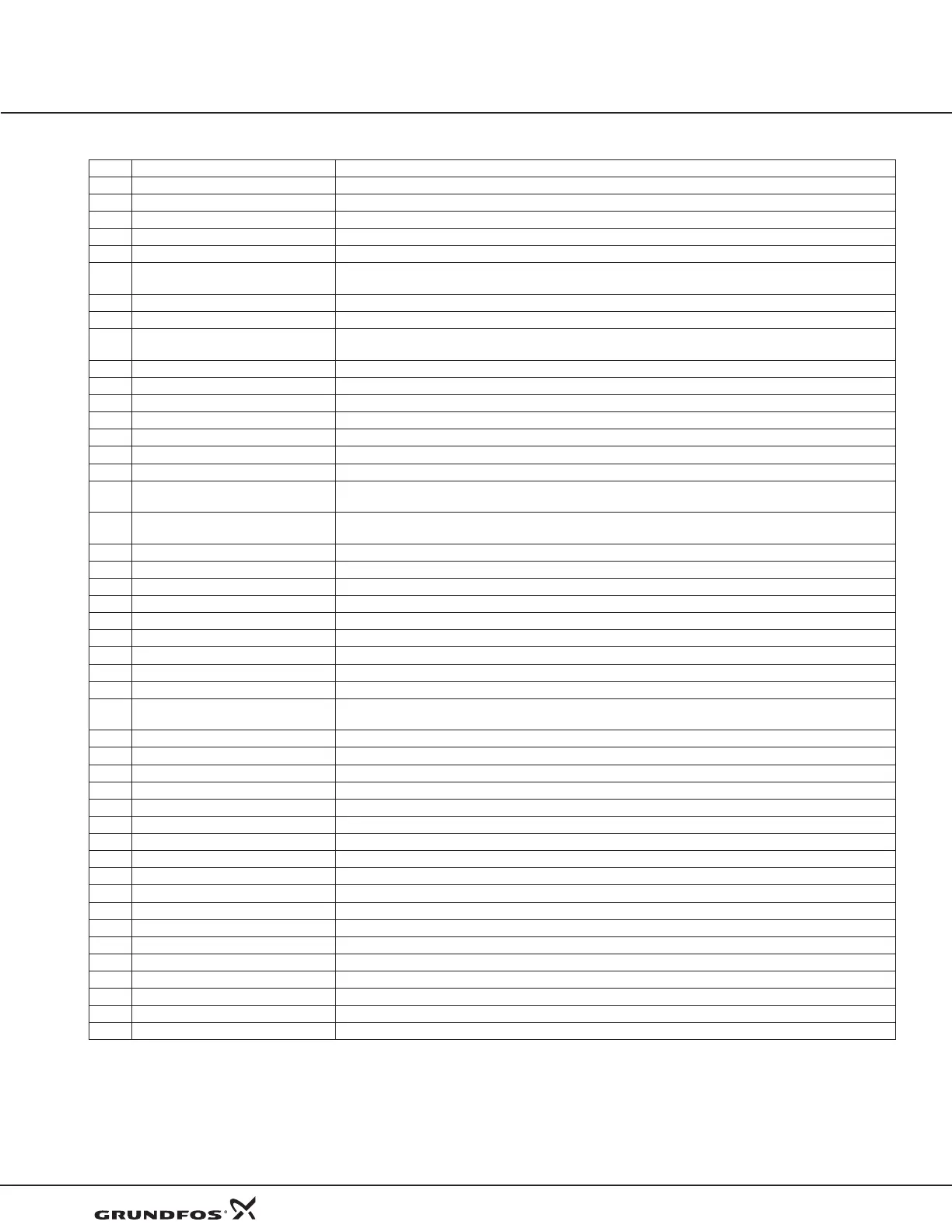

Troubleshooting 5‐9MN740

Fault Messages

Table 5‐1 Fault Messages

Type Fault Message Display Description

No fault exists Control is operating properly, no faults recorded.

F Unknown system fault Reset the control. Restore parameter values to factory settings.

F Configuration Reset the control. Restore parameter values to factory settings.

F SPI timeout Serial Peripheral Interface (SPI) failure between control board and power board. Check connections.

F Param checksum Reset the control. Restore parameter values to factory settings.

F New base ID Changing the Power Base, Control board, or new firmware will most often cause this error.

Reset the control. Restore parameter values to factory settings.

F Over current Motor current exceeded peak limit. Check: motor connections, motor load, increase accel/decel times.

F Desaturation Output current exceeds desat limit. Check: motor for short circuit, motor load, increase accel/decel times.

F Ground fault Ground Fault detected (output current leakage to ground).

Disconnect motor, check motor for insulation leakage to ground.

F Logic supply Logic power supply failure detected.

F Power Base Fault Usually occurs with other faults. Fault detected in power base, see FPGA in event log trace.

F Low Initial BUS Bus volt less than 200/400/500V on 230/460/575V units at power up. Check: line volt, resistors on R1/ R2.

F Current Sense Occurs on power up, motor current sensor(s) out of tolerance.

F User ref Internal reference power supply out of tolerance.

F User 24 V 24V at J1-23 and J1-24 out of spec. Check 24V, if below, remove wiring from terminal strip, re-check.

F Current reference Reference volt for current readings out of tolerance.

F Overload - 1 minute Peak output current exceeded the 1 minute rating value. Check motor and wires, Level 2 Pk CUR Limit value,

Accel time or reduce motor load. Change Level 2 Drive Protect, Overload to “Foldback” and try again.

F Overload - 3 seconds Peak output current exceeded the 3 second rating value. Check motor and wires, Level 2 Pk CUR Limit value,

Accel time or reduce motor load. Change Level 2 Drive Protect, Overload to “Foldback” and try again.

F Motor Overload Motor current exceeded preset limits: 125% for 590 sec., 150% for 150 sec. or 200% for 50 sec.

F Following Error Speed error beyond Set Speed Band parameter value. Verify motor is not overloaded.

F DC Bus High DC Bus V over 405/810/1000V for 230V/460V/575V units. Check line volt, decel rates, resistor on R1/ R2.

F DC Bus Low DC Bus V below 220/440/550V for 230V/460V/575V units. Check line volt, B+ to B- voltage.

F Drive Over TEMP Heatsink temp exceeded 85/95qC. Verify ambient does not exceed 45qC. Clean fans and heatsink.

F Drive Low TEMP Heatsink temp is less than allowed (-10qC).

F External trip Connection at J2-16 is open and P2201 is set to ON.

F Torque Proving Failed to measure current in one or more motor phases. Check motor connections or open motor contacts.

F Regen R or PWR Excessive resistor power dissipation. Check resistor ratings, extend decel times, or add larger braking kit.

F EEPROM fault (Powerbase EE,

Control EE, Flt Log Mem, NV memory)

EE memory. Reset the control. Restore parameter values to factory settings.

F Internal Config Software boot error. Reset the control. Restore parameter values to factory settings.

F Dyn Brake Desat Dynamic braking current limit exceeded. Check for shorted braking resistor circuit.

A Line Loss All 3 input phases lost. Check input circuit breaker, fuses or input contacts.

A Phase Loss One input phase lost. Check input circuit breaker, fuses or input contacts.

F U Upper Fault Power transistor gate fault on T1.

F U Lower Fault Power transistor gate fault on T1.

F V Upper Fault Power transistor gate fault on T2.

F V Lower Fault Power transistor gate fault on T2.

F W upper fault Power transistor gate fault on T3.

F W lower fault Power transistor gate fault on T3.

F Ph 1 pulse Phase 1 (T1) curr limiting via pulse by pulse method; check motor: spiking loads, chattering contacts.

F Ph 2 pulse Phase 2 (T2) curr limiting via pulse by pulse method; check motor: spiking loads, chattering contacts.

F Ph 3 pulse Phase 3 (T3) curr limiting via pulse by pulse method; check motor: spiking loads, chattering contacts.

F Network Timeout Forced network fault. Possible reason: watchdog, timing, user control.

F Memory Option card problem, memory failure.

A Aux Filter Setup Filter Source should be set to Raw Speed when destination is set to Speed Loop.

F Power Base FPGA Power base communication loss or invalid FPGA version.

A Sel FB Source Encoder Source Not Selected/Feedback Board is absent. Choose the appropriate card for encoder feedback.

F = Fault, A = Alarm

Loading...

Loading...