6

ASSEMBlING ThE REDI-FlO VFD SYSTEM

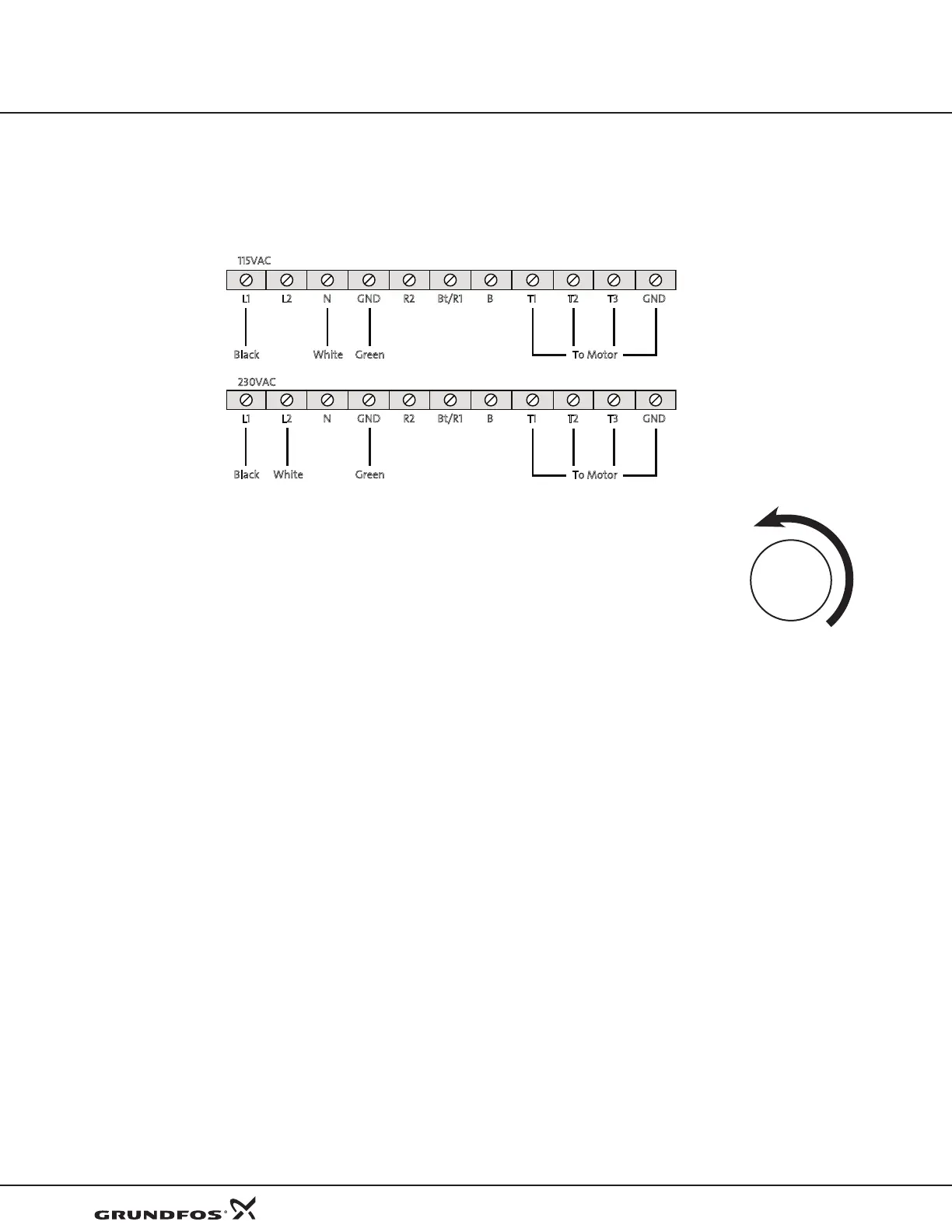

Input power terminals

The input voltage can be changed between 115V and 230V by changing the line input connections as shown below:

Warning – If the Redi-Flo VFD is miswired for the incoming voltage, internal damage may occur to the drive.

230VAC

115VAC

RGNDNL2L1

Black GreenWhite

2 Bt/R1 B- T1 T2 T3 GND

To Motor

To Motor

RGNDNL2L1

Black GreenWhite

2 Bt/R1 B- T1 T2 T3 GND

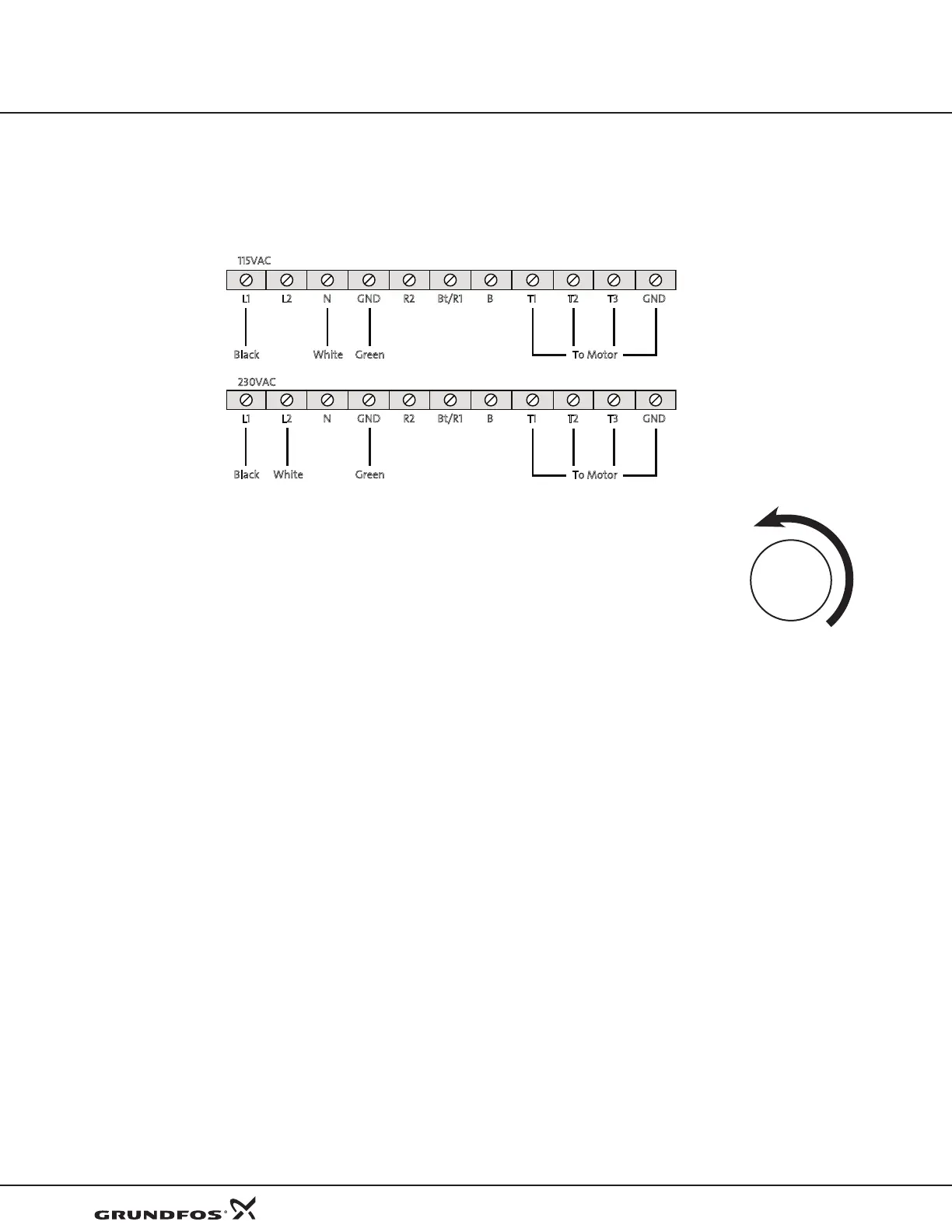

Reverse Rotation Test

Connect the motor lead to the Redi-Flo VFD and test the rotation of the pump. Submerge

the pump in water, start it at its slowest speed and make sure the pump shaft is turning

counterclockwise (when viewed from the top). If the rotation is incorrect, switching any two

power leads (with POWER OFF) will correct the problem.

Attaching the Pump to the Pipe

When connecting piping to the pump, a back-up wrench should be used. After the first section of pipe has been

attached to the pump, the safety cable should be connected to the pump (as shown if figure 6). Do not clamp

to the pump. When raising the pump, be careful not to place bending stress on the pump by picking it up by

the pump end only. It is recommended that a safety cable be attached to the pump (using special brackets and

cables, sold separately) anytime plastic pipe or flexible tubing is used. A check valve may also be added to

Redi-Flo2® pumps to prevent fluid from flowing back into the pump after it is turned off (backflow prevention). A

check valve is standard on Redi-Flo4™ pumps. Always check to ensure joints are fastened securely. The use of

a torque arrestor is not required when using the Redi-Flo VFD.

Lowering the Pump into the Well

Make sure the electrical motor leads are not cut or damaged in any way when the pump is being lowered into

the well. Do not use the motor leads to support the weight of the pump. To protect against surface water entering

the well and contaminating the well, the well should be finished off utilizing a locally approved well seal.

The motor lead should be secured to the discharge pipe at frequent intervals to prevent sagging, looping and

possible motor lead damage. Teflon® wire ties are recommended for environmental applications.

IMPORTANT

Plastic pipe and tubing tend to stretch under load. This stretching must be taken into account when securing

the motor lead to the riser pipe or tubing. Leave three to four inches of slack between clipped points. This

tendency to stretch will also affect the calculation of the pump setting depth. When plastic pipe or tubing is

used, it is recommended that a safety cable be attached to the pump to raise and lower it. Redi-Flo4™ pumps

are designed to accommodate this cable and Redi-Flo2® pumps can be fitted with a safety cable bracket (part

number 1A0019).

Top

View

Loading...

Loading...