4. Installation

PNEG-2381 2000 Series U-Trough Bin Sweep Auger Unload System (72' - 78') 41

Measuring Misalignment

Gates engineers say the best tool for measuring misalignment is a laser alignment device. However, when

one is unavailable, the next best tool is a straightedge such as a long level, a strip of extruded aluminum,

or a ruler, depending on the center distance of the drive. The laser tool and straightedge are used to

project the orientation of one sheave or sprocket face with respect to the other.

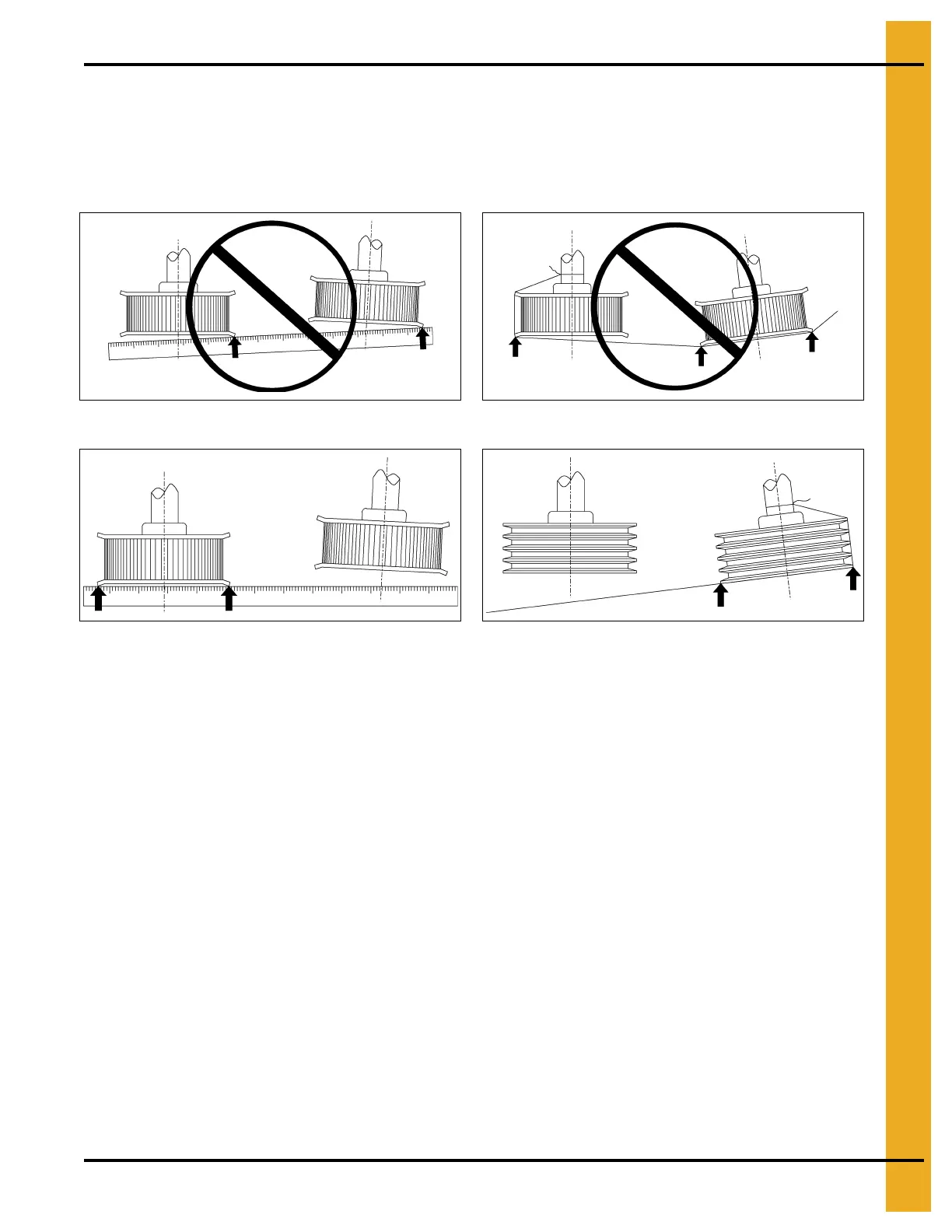

Figure 4BF Incorrect

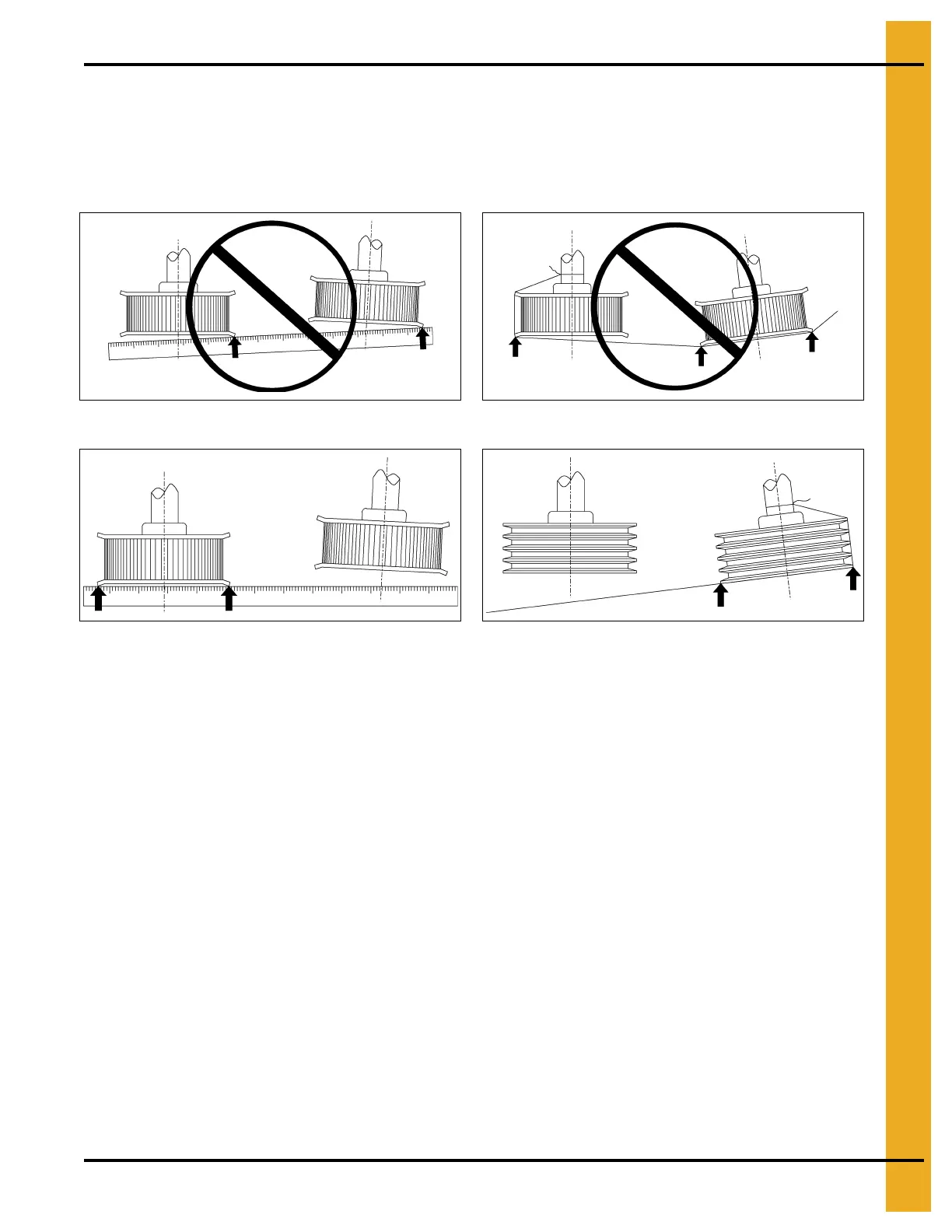

Figure 4BG Correct

Figure 4BH Incorrect

Figure 4BI Correct

When preparing to measure parallel misalignment, the maintenance technician must first verify that the

edges of both sheaves and sprockets are of equal thickness, or quantify the difference in thickness. It is

important to align the sheave grooves or sprocket faces directly in line with one another, rather than just

the outside surfaces of the sheaves or sprockets (flanges). It may be necessary to mount sheaves or

sprockets with the outside surfaces offset with respect to one another in order to properly align the grooves

or sprocket faces.

Sprocket flanges should also be inspected to be sure that they run true. A bent flange could result in

erroneous measurements if the laser tool or straightedge rests against the outside edge of the damaged

flange during the inspection process.

To determine how much misalignment is acceptable and at what point it becomes excessive, the

alignment must first be measured, quantified, and then compared to the belt manufacturer’s

recommendations for the particular type of belt. These recommendations can be found in drive design

manuals.

Quantifying Misalignment

Misalignment can either be quantified mathematically, or be compared to some general rules of thumb for

quicker and easier results. While using a straight edge to project the plane of the outside face of sheave

or sprocket #1 with respect to sheave or sprocket #2, angular misalignment can be quantified as the

difference in clearance between the straightedge and the outside surface of the sheave or sprocket #2

across the diameter.

Loading...

Loading...