4. Installation

42 PNEG-2381 2000 Series U-Trough Bin Sweep Auger Unload System (72' - 78')

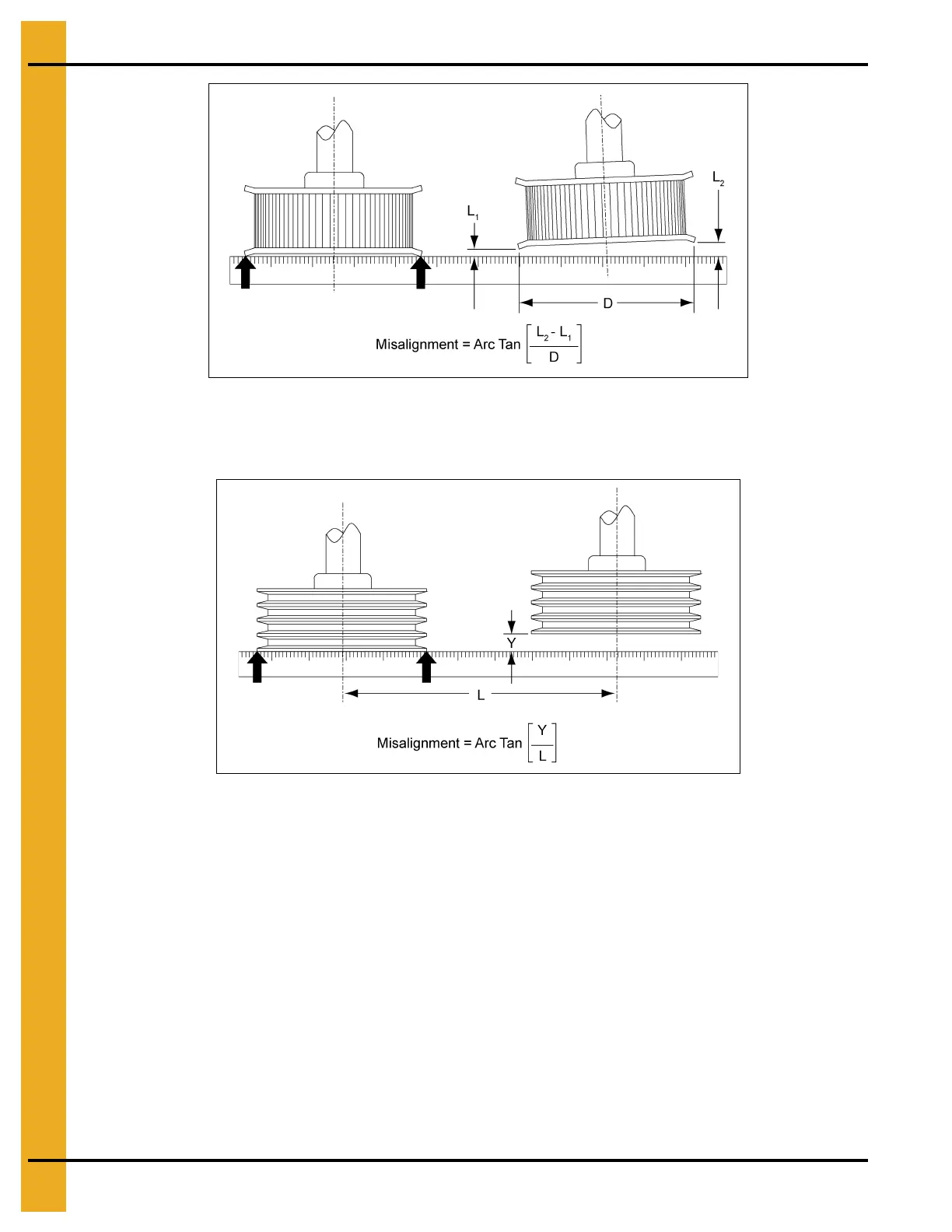

Figure 4BJ

The angle of parallel misalignment can be quantified as the difference in clearance between the

straightedge and the outer surfaces of the two sheaves or sprockets across the separation distance.

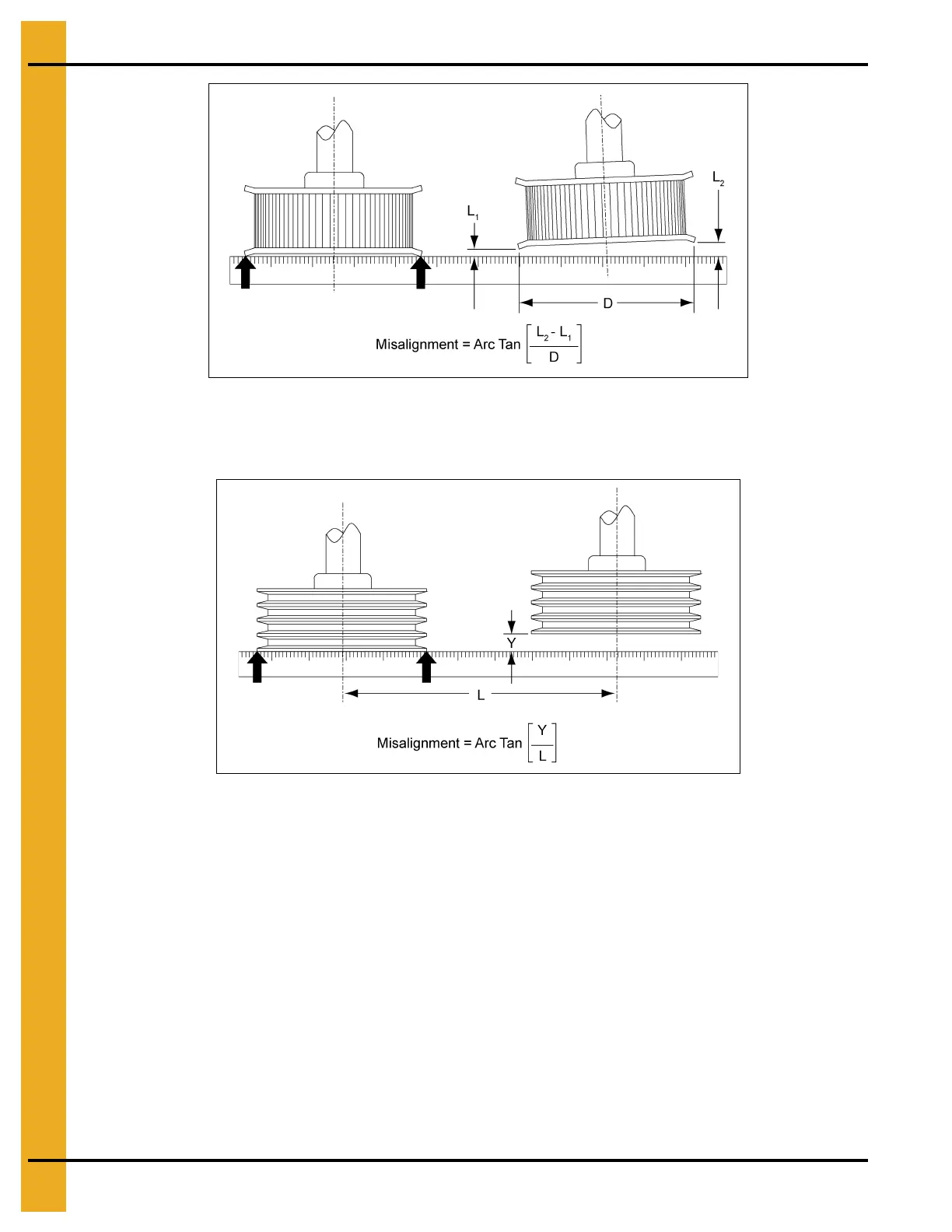

Figure 4BK

The total allowable misalignment recommended for V-belts, in general, is 1/2°. While individual V-belts are

known to be capable of handling greater amounts of misalignment before becoming unstable, maintaining

the misalignment to within 1/2° will maximize belt life.

The total amount of misalignment recommended for synchronous, urethane 60° belts (Polyflex), and

poly-V belts (Micro-V) is 1/4°. These drives are less tolerant of misalignment than conventional

V-belt drives, and must be aligned more accurately.

When determining if a V-type drive system is aligned within these recommendations, the angular and

parallel misalignment must both be measured and quantified individually, and then added together.

The total sum of angular and parallel misalignment can then be compared to the belt manufacturer’s

recommendations for the particular type of drive.

The sprockets for synchronous belts are made with face widths greater than the belt width to prevent belt

fit problems from tolerance accumulations. This additional sprocket face width allows the belt to free float

across the sprocket faces.

Loading...

Loading...