32

3.6.4 Duty cycle monitoring

The duty cycle monitoring ensures that when a defined duty cycle has been reached, the control unit is taken out of

operation for a defined time (e.g. after 2 minutes of continuous operation, the control unit is automatically disabled for

the next 18 minutes – the initiated lifting movement, however, can always be completed).

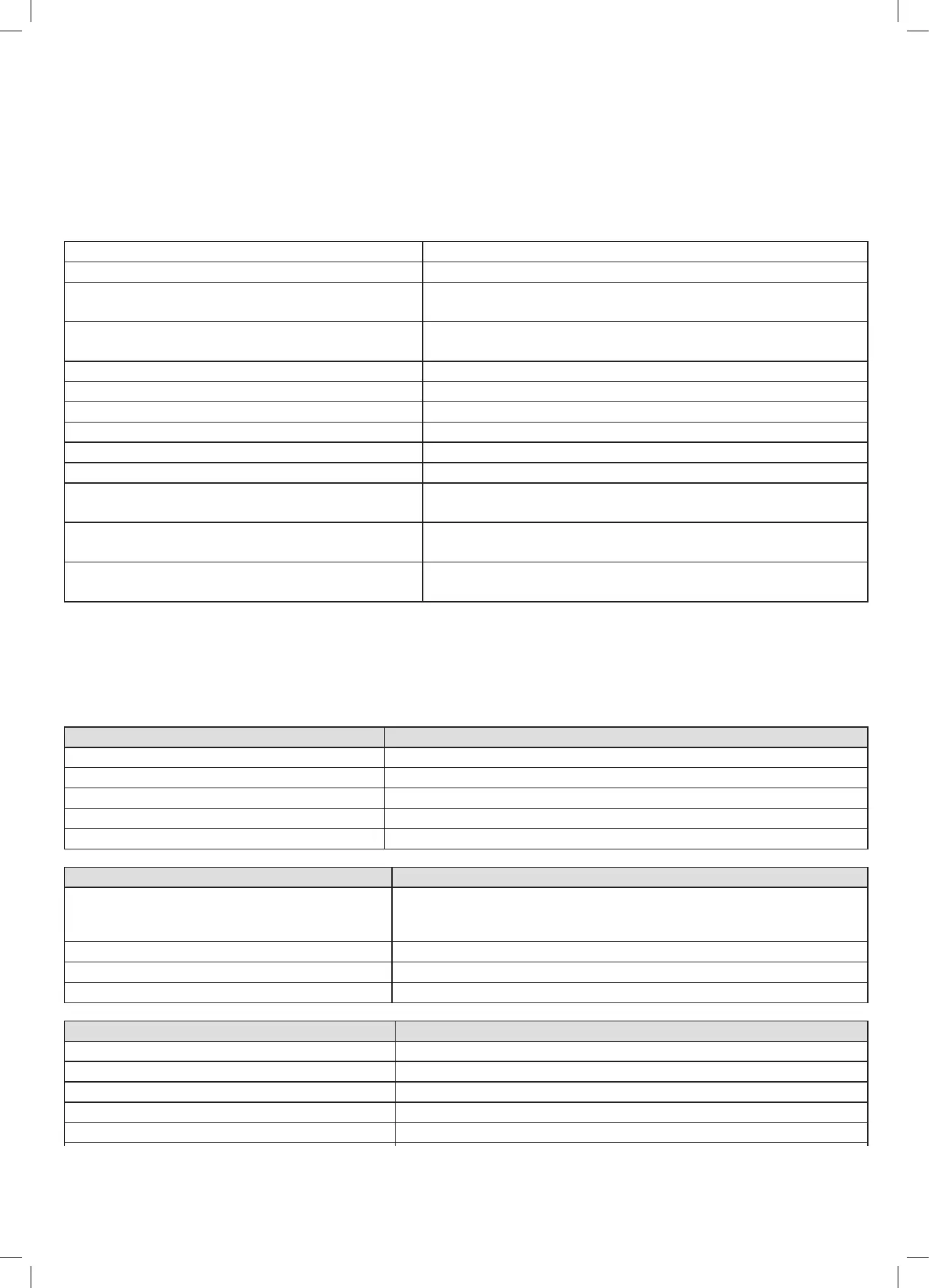

4. Technical data of the control unit

Standby power, (typically)

Operating voltage, internal and external

electronics and Hall sensors

Accuracy of the motor current measurement

at 100% output voltage and 4-8 A per motor

Relative humidity (for operation)

Storage and transport temperature

Relative humidity (for storage)

Dimensions of the control unit (L-W-H) [mm]

Tolerances

319x119x37 mm

In accordance with DIN ISO 2768-1 c

Normal-cycle 2/18:

2 min movement: 7 A@33 V 231 W Pause: 18 min

Max. current per motor channel

8 A per motor channel

Maximum total current limited

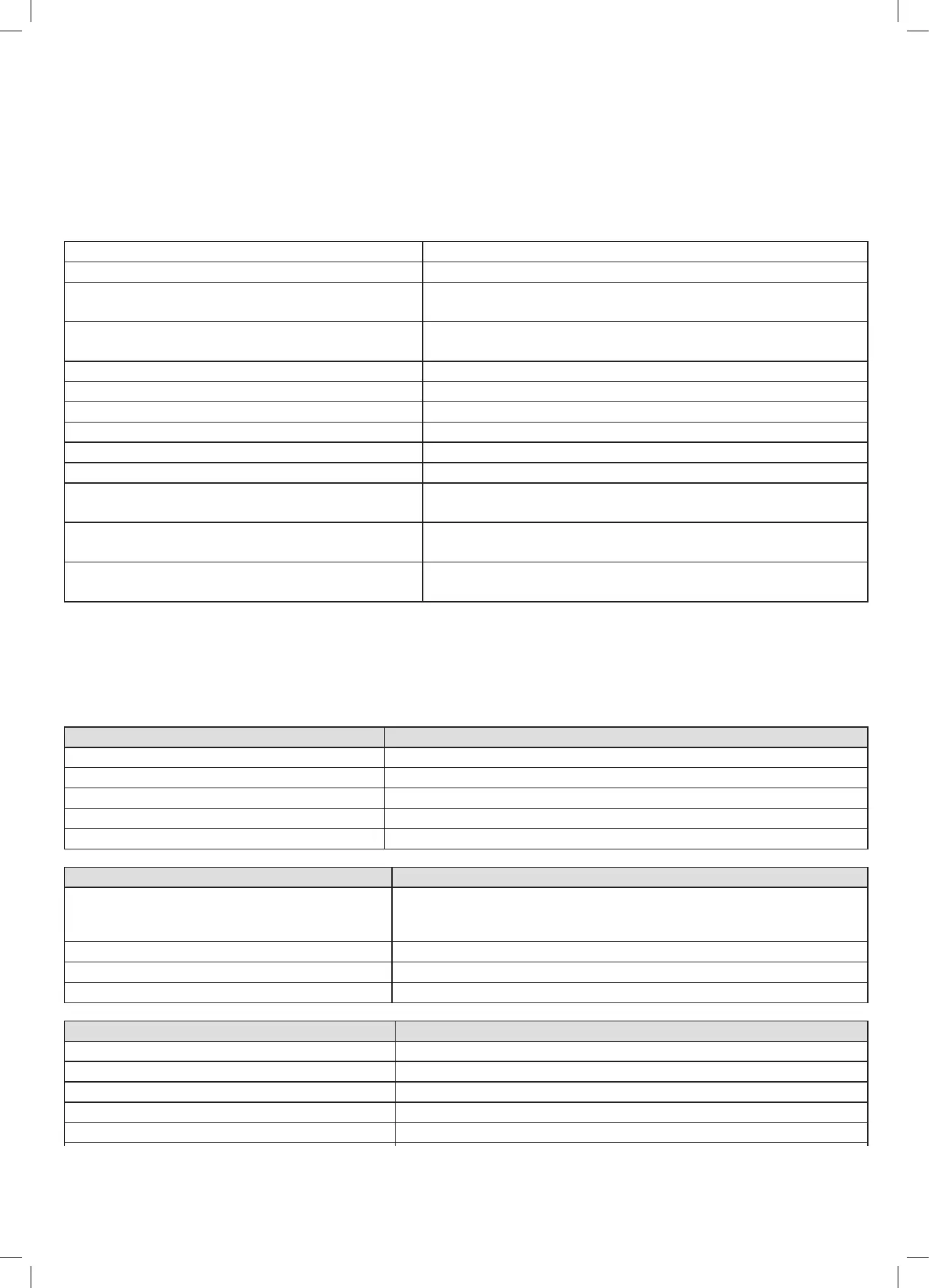

5. Trouble-Shooting

5.1 Possible faults and remedies

Drives do not function

Mains cable is not plugged in

Connect the mains cable of the control unit

The drives are not plugged in

Connect the motor cable with the control unit

Connect the motor cable, mains cable and the hand switch properly

Control unit is defective

Drives only run in one direction

Power outage during drive movement, or the

control unit was disconnected during drive

Manual reset (see section 3.3)

(If the drives only move downwards)

Control unit is defective

Control unit or hand switch do not function

Mains cable is not plugged in

Plug in the mains cable into the control unit

Control unit is defective

Hand switch is not plugged in

Connect the plug properly

3.

Operation of the desk

During the initial start-up process a reset is compulsory to put the product into operation.

Through the reset, e.g. of a desk, all lifting columns are brought to the same level in the middle desk position to ensure

that the desktop proceeds parallel to the floor level.

In the standard version, the control system remembers the settings of connected components like lifting column

positions and connected sensors (if any). After the reset, any configuration changes are detected and classified as

faults. The system will not proceed, until the saved settings are restored.

Danger: During reset the collision protection is inactive, and no detection is taking place.

Consequently there is an increased danger of pinching. You must therefore ensure that no people or

objects are located in the hazardous area (in the entire lifting and movement area of all components),

or can reach into it.

3.1 Operation of the hand switch – standard function

desktop up

desktop down

3.2 Operation of the hand switch – memory function

Desk/2nd motor group Containerstop-LED desktop up

(not occupied) Reset-LED

memory position key 1 save key memory position key 4

Desk/2nd motor group memory position key 2 memory position key 3 desktop down

(not occupied)

1.3 Important notes for service

Danger: In the event of a fault, please contact your customer service immediately. Only original spare

parts may be used for repairs. Parts may only be replaced by qualified service technicians; otherwise

the warranty/guarantee shall be null and void.

Danger: Never open the housing of the control unit or the hand switch.

Unauthorised opening and improper repairs could result in dangers for the user, and the entitlement to

guarantee claims shall be null and void.

Only the qualified technicians of the manufacturer are authorised to open or repair the electrical

equipment.

2. Functions and features

The desk system Contec-plus is exclusively intended for indoor use as office furniture in the commercial sector.

The hand switch of the desk serves as the control of the electrically powered, height-adjustable desk system.

The basic function is to raise and lower the desktop.

Advanced functions are to store height positions, and to move to these positions (memory control).

During commissioning, an initialization (manual reset) must be carried out (see section 3.3).

This will normally be carried out by the qualified technician of the specialized dealer/manufacturer during assembly

and commissioning at the installation site.

In the event of a power outage while the drives are operating, another reset must be carried out, before the desk can

be used normally again.

The reset movement will be performed at a reduced speed.

The movements of the drives are electronically monitored by the control unit. On exceeding the maximum duty cycle,

the electronics will prevent any further travel of the drives in order to protect the electrical and mechanical components

against overload.

In the event of unacceptably high temperatures, a shutdown will occur.

In this case, the LED display on the hand switch will blink, when pressing the keys.

The maximum duty cycle is 2 minutes, after which the control unit is automatically disabled for the next 18 minutes.

If the control system detects excessive weight loads it will also be automatically disabled.

The maximum distributed load of the desk is 70 kg.

The maximum noise emission during movement of the desk is 50dB(A).

After starting and before stopping, the drives will temporarily run at a reduced speed (soft start/soft stop).

A certain zone (ca. 40 mm before the lower end position), is defined as a safety area. If the drives reach this point, a

safety stop will be triggered. After pressing the key again, movement will be resumed at a reduced speed.

If a desk meets an obstruction when moving downwards, the internal collision protection system will prevent a tilting

position and stops the desk from toppling over. If an obstruction is detected, a safety function is triggered and the

desktop automatically moves a defined distance in the opposite direction.

Danger:

In spite of the collision protection system in place, there may still be a risk of pinching in exceptional cases.

For physical reasons „soft“ obstructions are difficult or impossible to detect and evaluate. In the event of a

collision with an obstruction, damage occurring to the obstruction cannot be ruled out.

5.2 Error messages on the hand switch display

The display reads HOT.

The control unit is fitted with overheating protection.

Overheating has caused it to stop.

Wait until the control unit has cooled down and the

display message HOT is no longer displayed. The

control unit is then operational again.

The display reads E + an error code

There is an internal fault in the control unit.

Proceed as indicated in the following error list.

Switch the control unit off. Contact customer service.

Unplug the control unit. Fix the external short circuit. Or, plug correct

motor into the corresponding socket. Start the control unit again.

Remove the jammed object from the area of movement.

Desk overloaded Remove the load from the desk.

Contact customer service.

Plug detection on motor socket M1

Plug correct motor into the corresponding socket.

Perform a reset (see section 3.3).

Plug detection on motor socket M2

Plug detection on motor socket M3

Synchronization of motor group 1

not possible

Remove the load from the desk. Perform a reset (see section 3.3).

If after the reset, the fault continues to be displayed, contact customer

service.

Synchronization of motor group 2

not possible

Unplug the control unit and contact customer service.

Drive configuration changed

Sensor configuration changed

Check to see if a sensor has come loose.

Unplug the control unit and wait at least 5 seconds. Put the control unit

into operation again and perform a reset (see section 3.3). If the fault

continues to be displayed, contact customer service.

Perform a reset (see section 3.3). Unplug the control unit, and after

several seconds plug it back in.

If this fault occurs regularly, unplug the control unit and contact

customer service.

Note: The Power Fail Detection detects power outages and saves all relevant data before the voltage

drops below a critical level.

In a few exceptional cases this may not be possible and when the control unit is next switched on, the

code E81 will be displayed and the control unit will click three times.

To remedy the fault a manual reset is necessary (see section 3.3).

Loading...

Loading...